The most popular leaf tarpaulin factory supply

The most popular leaf tarpaulin factory supply?

Ⅰ,What is the leaf tarpaulin?

Leaf tarpaulin ,we can also called the PE tarpaulin.

PE: chemical name for polyethylene, it is a semi crystalline thermoplastic material, manufacturing PE tarpaulin material.

So what are the characteristics of PE? We know that polyethylene is odorless, non-toxic, feel like wax, has excellent resistance to low temperature performance, has good water absorption, good electrical insulation properties, can be used normally in -70 to -100 degrees Celsius, good chemical stability.

PE tarpaulin production is generally used in HDPE (high density polyethylene), this material has high temperature, hardness, mechanical strength and good chemical resistance. Polyethylene for blow molding, injection molding and extrusion of various products (hard), such as a variety of containers, nets, packaging tape, and can be used as cable coating, pipes, profiles, sheets and so on.

PE tarpaulin material generally refers to the color of the cloth, cloth is in double coated PE film PE woven polypropylene woven cloth is also useful, its production process is: drawing roleaf tarpaulin

und - weaving - double side film. This tarpaulin waterproof performance is bad, generally used once can not guarantee waterproof performance, the disadvantage is easy to wear, the advantage is that its quality is light, clean and pollution-free. Generally used in temporary cargo, rain, dust-proof, not suitable for long-term use in the open air environment.

Ⅱ,Product description of Because of the high quality materials, the tarpaulins withstand all weather conditions. Strong sunshine as well as wind, frost and hail do not matter to the materials.

Ⅲ,PRODUCT FEATURES of leaf tarpaulin:

- Water Proof, Rot Proof &Mildew Resistant

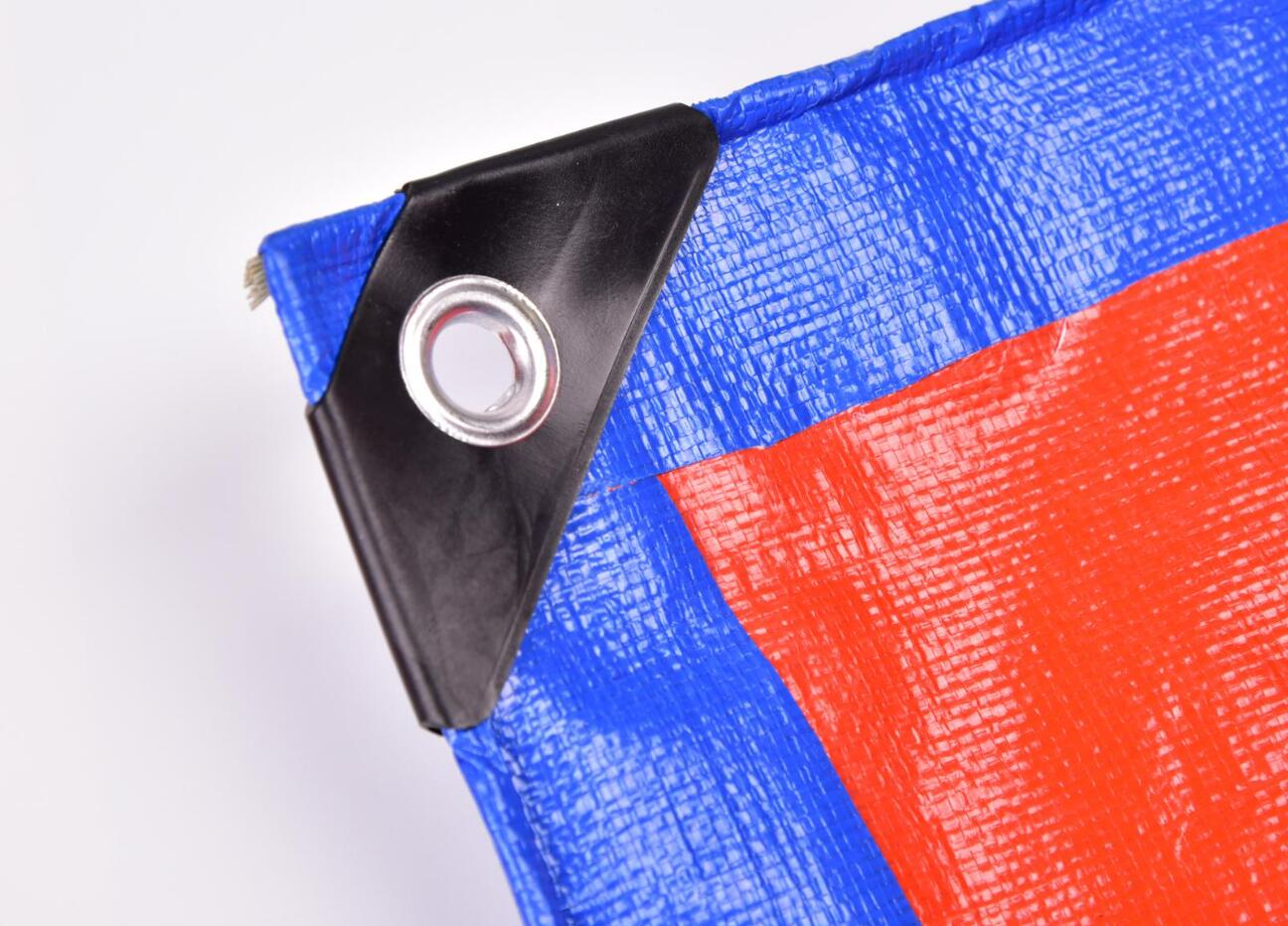

- Reinforced corners with grommets

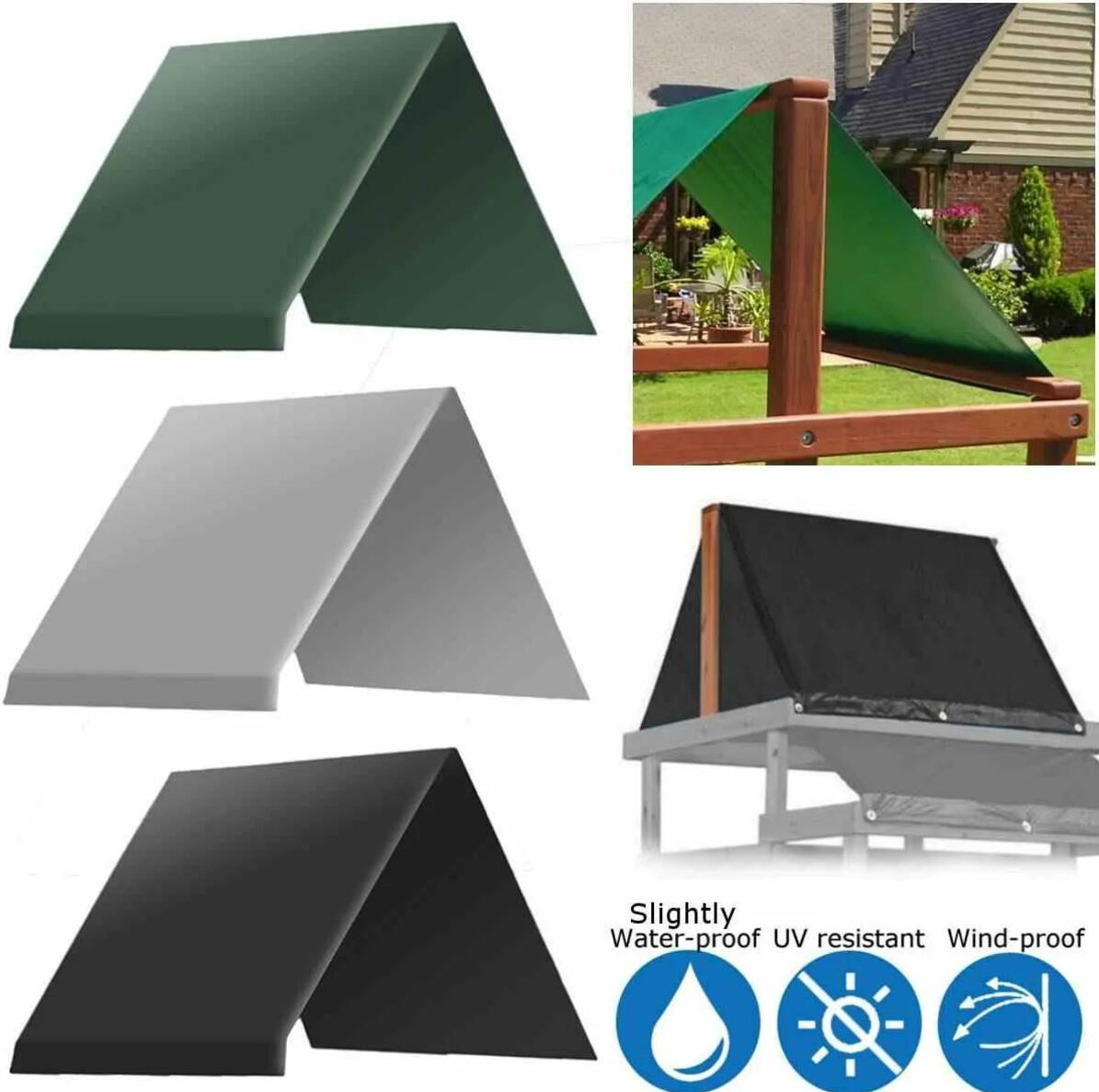

- Ideal for general cover tent fly, camping ground sheet, car covers, boat covers, machine covers, lumber covers, wind protectors, haystack cover, privacy walls, picnic mats and pool cover.

Ⅳ,Technical specifications of PE tarpaulin

- Material: PE plastic

- Gram weight: 200g/m2

Ⅴ,Versatile usage of heavy duty HDPE tarpaulin

- covering garden furniture, cars, motorcycles, bikes, boats, trailers, trucks, swimming pools, trampolines, BBQ grills, timbers, hutches, plants etc.

Ⅴ, Packaging of leaf tarpaulin roll

- After receiving the product, there may be a little glue smell Road, on the outside for ventilation

- Sizes listed are cut sizes, Finished sizes are about 20cm shorter in each dimension, All measurements with tolerances +/- 5%

- The displayed colour may slightly differ from the actual colour due to different settings of the monitor or screen

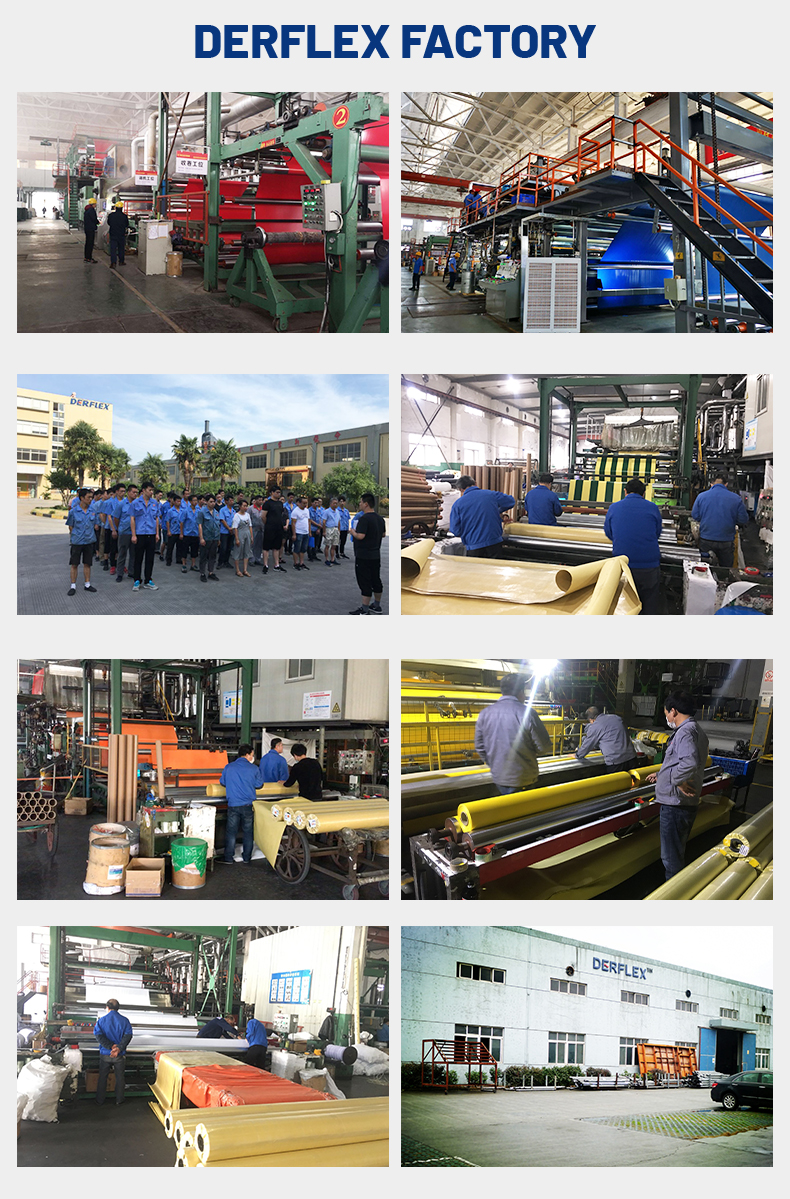

Ⅵ, About DERFLEX --The most popular leaf tarpaulin factory supply

1.Quality assurance: We will 100% return money if any quality problem, our QC department will inspect each order

before ship.

2.Experience: 20 years’ R&D and production experience.

3.Production area: 60,000 square meter, 20 senior engineers and 350 workers.

4.International exhibition: Every year we attend USA, Germany, Russia, Spain international exhibitions etc.

5.Product quality: Our enhanced products are products that combine European and American quality standards.

DERFLEX Production Lines

1. Knife coating production lines to make High adhesion coted fabrics, the high adhesion makes higher outdoor durance and Anti-UV characters

2. Hot-melt coating production line: With high water-resistant and water tight and air tight characters, which can make inflatable products

DERFLEX is exporting to more than 100 countries all over world.

Professional Sales and After-sale survice;

Experienced production team;

Good reputation on quality control;

Immediate response to customers' questions

Makes DERFLEX stronger business range on PVC coated fabrics industry, which can compete >95% products from other factories

Quality control

DERFLEX coated fabrics quality control process

During Production:

1. Online raw material quality control

2. Online surface flatness control

3. Online defects inspection

4. Online weight control

5. Fabric Structure

After production:

1. Roll Width

2. Roll Length

3. final product weight

4. tearing strength

5. breaking strength

6. adhesion

7. Aging test

8. Welding test

9. Abrasion test

10: Check fabric structure.

Application

DERFLEX Coated Fabrics applications

DERFLEX PVC knife coated tarpaulins widely used for tents, covers, inflatable products, water tank, fish tank, oil tank, air duct, oil boom etc. For any applications regarding waterproofing and anti-UV, DERFLEX coated fabrics would make most competitive constructions for you

Contact :

Sales manager: Masha

Cell Phone:+86-131 6285 8753(What"s App&Wechat)

Email: masha@derflex.com