PVC Membrane for Hydraulic Structures | Waterproof & Reinforced Engineering Membrane

PVC Membrane for Hydraulic Structures – Advanced Waterproof Solutions for Water Engineering

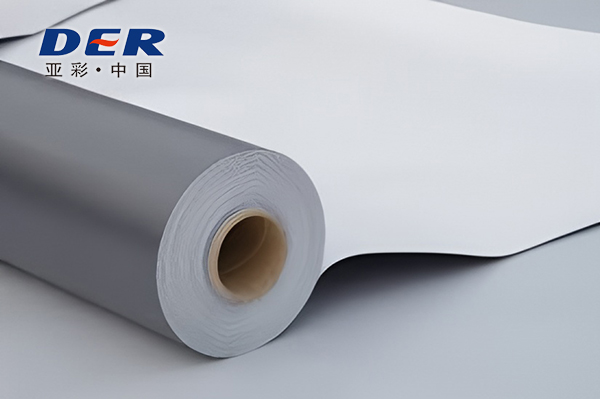

Derflex PVC Membrane for Hydraulic Structures is a high-performance engineered waterproof membrane specifically designed for modern hydraulic and water control infrastructure. Manufactured using reinforced polyester fabric combined with premium PVC formulations, this membrane delivers outstanding impermeability, mechanical strength, and long-term durability in demanding hydraulic environments.

Request Technical DatasheetProduct Overview

Hydraulic structures such as dams, reservoirs, canals, tunnels, spillways, and flood control systems require reliable waterproofing materials capable of withstanding constant water pressure, environmental exposure, and structural movement. Derflex PVC Membrane for Hydraulic Structures is engineered to meet these challenges through a combination of flexible reinforcement and advanced PVC coating technology.

Unlike rigid concrete liners or brittle geomembranes, PVC hydraulic membranes offer superior adaptability to structural deformation, reducing the risk of cracking, leakage, and long-term failure. This makes them an ideal solution for both new hydraulic construction and rehabilitation projects.

Applications in Hydraulic Engineering

- Dams and embankment waterproof lining

- Water reservoirs and storage basins

- Irrigation canals and water conveyance channels

- Hydropower stations and spillways

- Tunnels, culverts, and underground water structures

- Flood control and emergency water retention systems

- Industrial and municipal water treatment facilities

Key Performance Advantages

- Excellent Waterproof Performance – Fully impermeable PVC layer ensures zero water penetration.

- High Mechanical Strength – Reinforced polyester fabric resists tensile and tear stress.

- Flexibility & Structural Adaptability – Accommodates settlement and thermal movement.

- UV & Weather Resistance – Suitable for long-term outdoor exposure.

- Chemical & Biological Resistance – Resistant to algae, microorganisms, salts, and chemicals.

- Long Service Life – Designed for 10–30 years depending on application conditions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Base Fabric | High-tenacity polyester reinforced fabric |

| Coating | Flexible PVC with UV stabilizers |

| Weight Range | 700gsm – 2200gsm |

| Thickness | 0.7mm – 2.5mm |

| Tensile Strength | Up to 4500 N / 5cm |

| Tear Strength | ≥ 600 N |

| Water Pressure Resistance | 100% impermeable |

| Temperature Resistance | -30°C to +70°C |

| Standard Width | Up to 3.2 meters |

| Customization | Thickness, color, surface finish |

Installation Methods & Engineering Compatibility

Derflex PVC Membrane for Hydraulic Structures is compatible with multiple installation methods, including hot-air welding, high-frequency welding, and mechanical anchoring systems. This flexibility allows engineers and contractors to adapt installation techniques based on project scale, terrain complexity, and structural requirements.

The membrane conforms easily to slopes, curves, joints, and irregular substrates, minimizing stress concentration and enhancing long-term waterproof reliability.

PVC Membrane vs Traditional Hydraulic Lining Materials

- More flexible than HDPE geomembranes

- Lower crack risk compared to concrete liners

- Faster installation and reduced labor cost

- Easier repair and maintenance

- Better adaptability to complex hydraulic structures

Quality Control & Certifications

Derflex operates advanced production lines under ISO-certified quality management systems. Each batch of PVC hydraulic membrane undergoes strict inspection and laboratory testing to ensure consistent performance in hydraulic applications.

- ISO 9001 Quality Management System

- SGS third-party material testing

- UV aging and weather resistance tests

- Hydraulic pressure simulation tests

About Derflex – Trusted Manufacturer for Hydraulic Engineering Materials

Derflex is a professional manufacturer specializing in PVC coated fabrics and membranes for industrial, architectural, environmental, and hydraulic engineering applications. With more than 20 years of experience, Derflex supplies high-performance membranes to contractors, government projects, and engineering firms worldwide.

Our PVC membranes for hydraulic structures are trusted across Asia, Europe, Africa, the Middle East, and the Americas for their durability, consistency, and engineering reliability.

Global Project Applications

Derflex PVC Membrane for Hydraulic Structures has been applied in large-scale irrigation projects, reservoir waterproofing systems, flood control infrastructures, and hydropower facilities across diverse climates and geographic conditions.

Frequently Asked Questions

Is PVC membrane suitable for permanent hydraulic structures?

Yes. When correctly designed and installed, PVC membranes provide long-term waterproof protection for permanent hydraulic structures.

Can Derflex provide custom engineering solutions?

Yes. We offer OEM and ODM services including thickness, reinforcement, surface treatment, and color customization.

How does PVC membrane compare with HDPE geomembrane?

PVC membranes offer greater flexibility, easier welding, and better performance on uneven or complex hydraulic structures.

Contact Derflex for PVC Membrane for Hydraulic Structures

For technical consultation, project support, or quotation, contact Derflex today. Our engineering team will provide professional recommendations tailored to your hydraulic project requirements.

Contact Derflex