Waterproof Dry Bag Fabric | High Strength PVC & TPU Fabric for Dry Bags

Waterproof Dry Bag Fabric – Professional Materials for Durable & Reliable Dry Bags

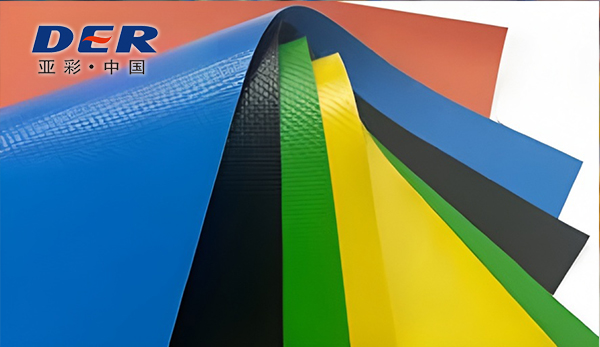

Derflex waterproof dry bag fabric is engineered for manufacturers of dry bags, waterproof backpacks, marine bags, and outdoor adventure gear. Designed to provide complete waterproof protection, high tear strength, and long-term durability, our dry bag fabrics are trusted by global brands and OEM factories.

Request Fabric SamplesProduct Overview

Waterproof dry bag fabric is the core material used to manufacture roll-top dry bags and sealed waterproof storage solutions. These bags are essential for protecting gear and valuables in environments exposed to water, rain, mud, sand, and harsh weather conditions.

Derflex produces premium waterproof dry bag fabrics using advanced PVC coating and TPU lamination technologies. By combining high-density base fabrics with flexible waterproof coatings, our materials deliver excellent impermeability, abrasion resistance, and mechanical strength while maintaining ease of welding and fabrication.

Applications of Waterproof Dry Bag Fabric

- Outdoor dry bags for hiking, camping, and trekking

- Waterproof bags for kayaking, rafting, and canoeing

- Marine dry bags and sailing storage solutions

- Waterproof backpacks and duffel bags

- Motorcycle and cycling waterproof luggage

- Military, rescue, and emergency waterproof storage bags

Available Material Types

PVC Coated Dry Bag Fabric

PVC coated dry bag fabric is widely used due to its excellent waterproof performance, cost efficiency, and strong weldability. It is ideal for mass production of dry bags where durability and price balance are required.

TPU Laminated Dry Bag Fabric

TPU dry bag fabric offers superior flexibility, cold resistance, and environmental friendliness. It is commonly used for premium dry bags and applications requiring soft hand-feel and low-temperature performance.

Key Performance Advantages

- 100% Waterproof Protection – Fully sealed surface prevents water penetration.

- High Tensile & Tear Strength – Reinforced base fabric ensures durability.

- Excellent Weldability – Suitable for hot-air, RF, and ultrasonic welding.

- Abrasion & Puncture Resistance – Ideal for rugged outdoor use.

- UV & Weather Resistance – Maintains performance under prolonged sunlight.

- Custom Colors & Finishes – Matte, glossy, embossed, or printed surfaces.

Technical Specifications

| Parameter | Specification Range |

|---|---|

| Base Fabric | Polyester / Nylon |

| Coating / Lamination | PVC / TPU |

| Weight | 250gsm – 900gsm |

| Thickness | 0.25mm – 0.9mm |

| Tensile Strength | Up to 3000 N / 5cm |

| Tear Strength | ≥ 300 N |

| Waterproof Rating | 100% impermeable |

| Standard Width | Up to 2.6 meters |

| Operating Temperature | -30°C to +70°C |

Manufacturing & Processing Compatibility

Derflex waterproof dry bag fabric is optimized for efficient bag production. The material supports multiple fabrication methods, including hot-air welding, high-frequency welding, sewing combined with seam sealing, and adhesive bonding.

Our consistent coating thickness and surface quality ensure stable welding strength, reducing defect rates and improving production efficiency for dry bag manufacturers.

Quality Control & Certifications

Derflex maintains strict quality management systems throughout raw material sourcing, coating, lamination, and final inspection. Each batch of dry bag fabric is tested for waterproof performance, tensile strength, abrasion resistance, and aging performance.

- ISO 9001 Quality Management System

- SGS & third-party material testing

- Water immersion and hydrostatic tests

- UV aging and abrasion resistance tests

About Derflex – Professional Waterproof Fabric Manufacturer

Derflex is a leading manufacturer of PVC coated and TPU laminated fabrics, serving outdoor, marine, industrial, and protective applications. With over 20 years of experience, Derflex supplies waterproof materials to OEM factories, global brands, and distributors worldwide.

Our waterproof dry bag fabrics are exported to more than 100 countries and are trusted for their consistent quality, competitive pricing, and technical support.

Global Market Applications

Derflex waterproof dry bag fabric has been used in outdoor equipment markets across North America, Europe, Australia, and Asia. The material performs reliably in extreme conditions, including marine environments, alpine climates, and tropical regions.

Frequently Asked Questions

Is Derflex dry bag fabric suitable for roll-top dry bags?

Yes. Our fabrics are specifically designed for roll-top and welded dry bag constructions.

Can Derflex provide customized colors and branding?

Yes. We offer OEM and ODM services including color matching, surface embossing, and logo printing.

PVC or TPU – which is better for dry bags?

PVC is cost-effective and durable, while TPU offers better flexibility and eco-friendly performance for premium products.

Contact Derflex for Waterproof Dry Bag Fabric

Looking for a reliable waterproof fabric supplier for dry bags? Contact Derflex today for samples, technical data, and competitive quotations.

Contact Derflex