Flex Banner Material Manufacturer | PVC Flex Banner Printing Material Supplier

Flex Banner Material Manufacturer & Supplier

Company: DERFLEX | Website: https://www.derflex.com

Flex Banner Material Overview

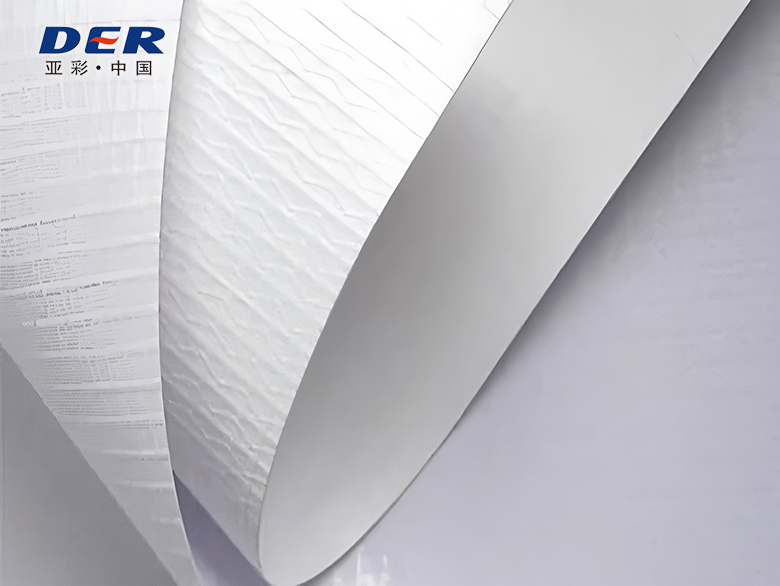

Flex banner material is one of the most widely used advertising substrates in the global signage and outdoor advertising industry. Made from PVC coated polyester fabric, flex banners are designed for large-format digital printing, offering excellent durability, print quality, and cost efficiency.

DERFLEX is a professional flex banner material manufacturer and exporter, supplying a full range of frontlit, backlit, blockout, and specialty flex banner materials to printing companies, advertising agencies, and distributors worldwide.

What Is Flex Banner Material?

Flex banner material refers to PVC coated textile designed specifically for printed advertising applications. It typically consists of a woven polyester scrim base fabric laminated or coated with PVC on both sides, creating a smooth, printable surface.

Flex banners are compatible with solvent, eco-solvent, UV, and latex printing technologies, making them suitable for both indoor and outdoor promotional use.

Types of Flex Banner Material

Frontlit Flex Banner

Frontlit flex banner is the most common type, designed for illumination from the front. It offers excellent image clarity and vibrant colors, making it ideal for billboards and outdoor signage.

Backlit Flex Banner

Backlit flex banner material allows light to pass through evenly, producing bright and uniform illumination when used with lightboxes and LED displays.

Blockout Flex Banner

Blockout flex banner features a black middle layer that prevents light transmission, making it suitable for double-sided printing and roll-up displays.

Specialty Flex Banners

DERFLEX also offers specialty options including anti-UV, anti-cold crack, and high-gloss flex banner materials.

Key Advantages of DERFLEX Flex Banner Material

Excellent Printability

Our flex banner materials feature optimized surface coatings that ensure superior ink absorption, color saturation, and image sharpness.

Strong Mechanical Performance

High-quality polyester scrim provides excellent tensile strength and tear resistance, suitable for large-format outdoor installations.

Weather & UV Resistance

DERFLEX flex banners are engineered to resist UV radiation, rain, wind, and temperature variations, ensuring long outdoor service life.

Cost-Effective Advertising Solution

Flex banner material offers an excellent balance between performance and cost, making it one of the most economical advertising substrates.

Wide Customization Options

We provide a wide range of weights, widths, finishes, and coatings to meet different market and application requirements.

Technical Specifications of Flex Banner Material

| Item | Specification Range |

|---|---|

| Base Fabric | Polyester scrim |

| Coating | PVC |

| Weight | 280gsm – 510gsm |

| Weave | 200x300D – 500x500D |

| Printing Method | Solvent / Eco-solvent / UV / Latex |

| Standard Width | Up to 5.1m |

| Outdoor Durability | 1–3 years |

Applications of Flex Banner Material

Outdoor Billboards

Flex banners are extensively used for large outdoor billboards due to their durability and vibrant print results.

Indoor & Outdoor Signage

Shopping malls, retail stores, and exhibition halls rely on flex banner material for cost-effective signage.

Lightbox Displays

Backlit flex banners are widely used in LED lightboxes and illuminated advertising displays.

Event & Promotion Advertising

Temporary events, promotions, and exhibitions benefit from the easy handling and installation of flex banners.

Flex Banner Material vs Other Banner Materials

- More economical than textile banners

- Better weather resistance than paper-based signage

- Wide compatibility with printing technologies

DERFLEX Manufacturing Capability & Quality Control

DERFLEX operates advanced PVC coating and lamination lines. Each roll of flex banner material undergoes strict inspection including thickness control, tensile strength testing, ink adhesion evaluation, and aging tests.

Global Export Experience

DERFLEX flex banner materials are exported to more than 120+ countries, serving advertising markets in North America, Europe, South America, the Middle East, Africa, and Asia.

Sustainability & Environmental Responsibility

DERFLEX is committed to improving production efficiency and developing durable flex banner materials to reduce waste and environmental impact.

Frequently Asked Questions (FAQ)

How long does flex banner material last outdoors?

Depending on coating and environmental conditions, outdoor durability typically ranges from 1 to 3 years.

Can flex banner material be welded?

Yes. Flex banners can be welded using high-frequency or hot-air welding for large installations.

Is customization available?

DERFLEX offers full customization including weight, width, coating type, and surface finish.