Membrane Roofs | Architectural Tensile Membrane Roofing Solutions

Membrane Roofs

Manufacturer: DERFLEX | Official Website: https://www.derflex.com

Advanced Membrane Roofing Systems for Modern Architecture

Membrane roofs represent a revolutionary approach to modern architectural design, combining lightweight structures with exceptional durability, flexibility, and aesthetic freedom. DERFLEX specializes in manufacturing high-performance membrane roofs using advanced coated fabrics and tensile membrane technologies, serving architects, engineers, and construction companies worldwide.

As a professional manufacturer of functional coated textiles, DERFLEX provides membrane roofing materials engineered for long-term outdoor performance, energy efficiency, and structural reliability. Our membrane roof solutions are widely applied in stadiums, airports, commercial complexes, exhibition halls, parking structures, transportation hubs, and public spaces.

What Are Membrane Roofs?

Membrane roofs, also known as tensile membrane roofs or fabric roofing systems, are architectural structures made from high-strength flexible membranes that are tensioned and supported by steel frames, cables, or air pressure. Unlike traditional rigid roofing systems, membrane roofs rely on tensile forces to achieve stability, enabling large-span coverage with minimal structural weight.

DERFLEX membrane roofs are designed to deliver outstanding performance in terms of weather resistance, UV protection, fire retardancy, and visual appeal.

Key Advantages of DERFLEX Membrane Roofs

- Lightweight Structure: Reduced structural load compared to conventional roofing materials.

- Large Span Capability: Ideal for stadiums, arenas, and public spaces requiring column-free design.

- Excellent Durability: Resistant to UV radiation, wind, rain, snow, and temperature extremes.

- Design Flexibility: Enables complex shapes, curves, and iconic architectural forms.

- Energy Efficiency: High reflectivity and translucency options reduce energy consumption.

- Fast Installation: Prefabricated membrane panels allow quicker construction timelines.

Membrane Materials Used in DERFLEX Roofing Systems

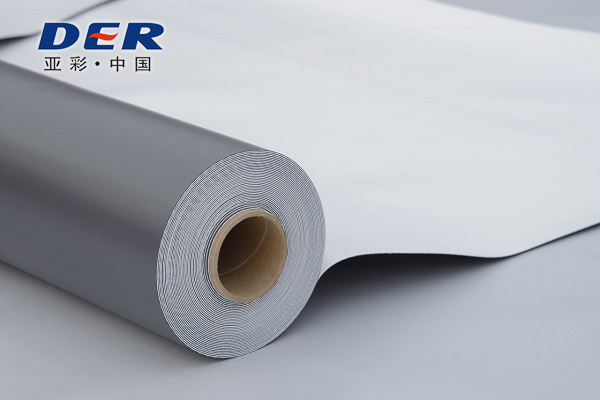

PVC Coated Polyester Membrane Roofs

PVC membrane roofs are the most widely used tensile fabric structures due to their excellent balance of cost, durability, and performance. DERFLEX PVC membranes feature high tensile strength polyester base fabric coated with PVC and optional PVDF or acrylic top coatings.

- Service life: 15–25 years

- High flexibility and weldability

- Excellent waterproof performance

- Available in multiple colors and translucency levels

PVDF Coated Membrane Roofs

PVDF-coated membrane roofs offer enhanced self-cleaning properties and superior resistance to dirt accumulation. DERFLEX PVDF membranes are ideal for architectural projects requiring long-term aesthetic performance.

PTFE Fiberglass Membrane Roofs

PTFE membrane roofs are engineered for extreme durability and longevity. With a fiberglass base fabric and PTFE coating, these membranes provide exceptional resistance to UV radiation, chemicals, and fire.

- Service life exceeding 30 years

- Non-combustible and fire-resistant

- Excellent light transmission

ETFE Membrane Roofing Systems

ETFE roofing systems use lightweight fluoropolymer films, often configured as air-inflated cushions. DERFLEX ETFE membranes offer superior transparency and energy efficiency, making them popular for stadiums, atriums, and botanical gardens.

Structural Performance & Engineering Design

DERFLEX membrane roofs are engineered to meet international building codes and structural standards. Each membrane fabric is tested for tensile strength, tear resistance, elongation, and weather resistance.

Our membranes are compatible with various structural systems, including:

- Cable-supported tensile structures

- Steel frame-supported membrane roofs

- Air-supported membrane structures

Weather Resistance & Long-Term Durability

DERFLEX membrane roofs are designed to withstand harsh environmental conditions:

- UV resistance for long-term outdoor exposure

- High wind load resistance

- Snow load and rainwater management

- Anti-mildew and anti-aging coatings

Fire Safety & Compliance

Fire performance is critical in architectural membrane roofs. DERFLEX membrane materials comply with international fire standards, including flame retardant and fire-resistant classifications depending on material selection.

Applications of Membrane Roofs

- Sports stadiums and arenas

- Airport terminals and transportation hubs

- Commercial complexes and shopping malls

- Exhibition centers and convention halls

- Parking structures and canopies

- Walkway shelters and public plazas

Customization & OEM Manufacturing

DERFLEX provides comprehensive OEM and customization services for membrane roofing projects:

- Custom fabric specifications

- Color, translucency, and coating options

- Project-based technical support

- Large-scale production capacity

Quality Control & Manufacturing Excellence

DERFLEX operates advanced coating and laminating production lines with strict quality control systems:

- Raw material inspection

- Mechanical and physical testing

- Weathering and aging tests

- Batch traceability and consistency control

Sustainability & Environmental Responsibility

Membrane roofs contribute to sustainable architecture by reducing material usage, enabling natural daylighting, and lowering energy consumption. DERFLEX continuously invests in eco-friendly coatings and long-life membrane solutions.

Why Choose DERFLEX as Your Membrane Roof Manufacturer

With extensive experience in coated fabrics and architectural membranes, DERFLEX is a trusted global supplier for membrane roofing projects.

- Manufacturer-direct supply

- Stable quality and large production capacity

- Global export experience

- Professional technical and material support

Frequently Asked Questions (FAQ)

How long do membrane roofs last?

Depending on material selection, membrane roofs can last from 15 to over 30 years.

Are membrane roofs waterproof?

Yes, DERFLEX membrane roofs are fully waterproof with high-frequency welded seams.

Can membrane roofs withstand strong winds?

When properly engineered, membrane roofs can withstand high wind and snow loads.

Next:Food Delivery Bags | waterproof delivery bags