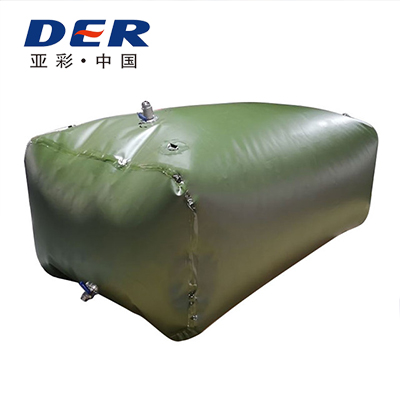

What Is an Oil Bladder?

An oil bladder (also known as a fuel bladder, collapsible fuel tank, or flexible oil storage bag) is a portable, lightweight, flexible container designed for the storage and transport of fuels and industrial liquids. DERFLEX manufactures oil bladders using industrial-grade PVC coated fabric and TPU fuel-grade coated textiles, meeting international standards for chemical stability, tensile strength, and fuel compatibility.

With a 20+ year manufacturing history, DERFLEX is one of China's leading suppliers of flexible liquid storage materials used in:

- Military fuel transport

- Mining and construction sites

- Remote fuel supply stations

- Aviation and helicopter refueling

- Marine and offshore platforms

- Emergency fuel or oil spill response

Our oil bladders are engineered for harsh environments and long-term durability, offering a safe and efficient alternative to rigid metal tanks.

Oil Bladder Material Options

1. TPU Fuel-Grade Coated Fabric (Premium Option)

TPU (Thermoplastic Polyurethane) is the best material for high-performance fuel bladders due to its outstanding:

- Chemical and hydrocarbon resistance

- Cold resistance down to –50°C

- High tensile and tear strength

- Environmental friendliness

- Long service life (8–15 years)

2. PVC Coated Fabric (Cost-Effective Option)

PVC oil bladder materials are suitable for engineering oils, diesel, and non-aggressive fuels. Key benefits:

- Economical and durable

- Strong welding performance

- High puncture resistance

- Thicker surface coating

3. Reinforced Base Fabric Options

- Polyester 1000D

- Polyester 1500D

- High-Tenacity Polyester Scrim

Each bladder is reinforced with welded seams, chemical-resistant coatings, and heavy-duty fittings.

Oil Bladder Technical Specifications

| Parameter | Specification |

|---|---|

| Material Options | TPU coated fabric / PVC coated fabric |

| Weight | 600gsm – 1800gsm |

| Thickness | 0.5mm – 1.4mm |

| Capacity Range | 100L – 300,000L |

| Chemical Resistance | Aviation fuel, diesel, JP-8, gasoline, lubricants, hydraulic oils |

| Temperature Resistance | –50°C to +70°C (TPU), –20°C to +60°C (PVC) |

| Standard Fittings | Aluminum/steel valves, drain ports, vents |

| Welding Technology | High-frequency welding / Hot air welding |

Available Colors

DERFLEX provides multiple functional and industrial colors:

- Army Green

- Desert Tan

- Navy Blue

- Black

- Grey

- Orange (Emergency Type)

- Custom Pantone Colors

Applications of Oil Bladder Tanks

✔ Military & Defense

Rapid deployment for field fuel supply operations.

✔ Aviation & Helicopter Fuel Supply

Compatible with Jet-A, JP-5, JP-8, AvGas.

✔ Marine, Offshore & Harbor Fuel Systems

Corrosion-resistant materials for long-term marine reliability.

✔ Mining, Forest & Construction Sites

Temporary or mobile fuel stations.

✔ Disaster Relief & Emergency Response

Ideal for post-disaster fuel storage and rapid supply.

✔ Residential & Agricultural Use

Safe storage of diesel or heating oils.

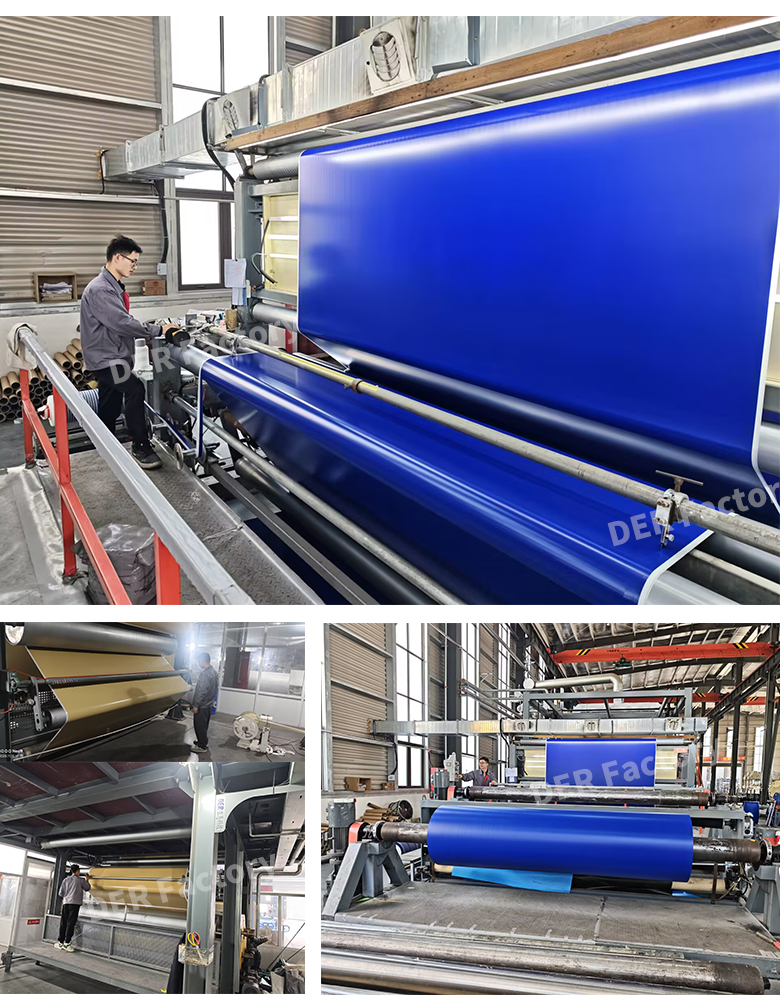

DERFLEX Company Profile

DERFLEX is a professional manufacturer of industrial coated fabrics and flexible liquid storage materials with more than 20 years of experience. Our factory is equipped with advanced knife-coating lines, calendering equipment, laminated production, HF welding technology, and intelligent QC systems.

We supply OEM fuel bladder materials and complete bladder tank systems to 120+ countries, serving industries such as military, energy, environmental protection, aviation, and marine engineering.

Our mission is to provide safe, reliable, and durable flexible storage solutions that perform in the harshest conditions.

Certifications

- ISO 9001 Quality Management Certification

- REACH Compliance

- RoHS Certification

- MSDS for TPU/PVC materials

- SGS Mechanical Testing

- Environmental Impact Report (Eco-Friendly Materials)

Why Choose DERFLEX?

✔ 20+ Years Industrial Manufacturing

Stable production, mature technology, and strong quality control.

✔ Global OEM/ODM Capabilities

Custom capacities, shapes, colors, materials, and fittings.

✔ Complete Material System

PVC, TPU, reinforced composites, chemical-resistant coated fabrics.

✔ Professional Engineering Support

Technical guidance for installation, welding, and application.

✔ Competitive Factory Prices

Large-scale production ensures cost advantages.

✔ Exported to 120+ Countries

Trusted by military suppliers, aviation companies, and fuel service providers.

Installation & Usage Precautions

- Ensure the ground surface is flat, clean, and free of sharp objects.

- Use a protective ground mat for rocky or uneven surfaces.

- Avoid dragging the bladder when filled with fuel.

- Regularly check valve connections for tightness.

- Do not exceed recommended pressure or fill level.

- Store in ventilated and shaded areas when not in use.

- For aviation fuel, use certified fittings only.

Countries We Export Oil Bladders To

DERFLEX products are widely supplied to:

- USA, Canada, Mexico

- Germany, UK, Italy, Spain

- UAE, Saudi Arabia, Qatar

- Australia, New Zealand

- South Africa, Kenya, Egypt

- Brazil, Chile, Peru

- Indonesia, Philippines, Japan, Korea

FAQs About Oil Bladders

1. What capacities are available?

From 100 liters to 300,000 liters. Custom sizes available.

2. Can oil bladders store gasoline?

Yes, TPU is recommended due to chemical resistance.

3. How long does an oil bladder last?

TPU: 8–15 years, PVC: 5–8 years depending on usage.

4. What accessories are included?

Valves, vents, repair kits, ground mats, and optional metal frames.

5. Can you manufacture custom-shape bladders?

Yes. Pillow type, onion type, cube type, and reinforced military types.