Agricultural Bale Wrap Film Manufacturer – High-Strength Silage Wrap Film

DERFLEX is a trusted agricultural bale wrap film manufacturer with more than 20 years of experience in industrial polymer materials and agricultural packaging solutions. Our agricultural bale wrap film is designed for silage preservation, hay storage, moisture protection, oxygen resistance, and long-term farm efficiency.

Made with premium LLDPE + multi-layer co-extrusion technology, DERFLEX bale wrap film offers excellent tensile strength, UV stability, puncture resistance, and airtight sealing to ensure optimal fermentation and stable fodder quality for livestock and dairy farms.

What Is Agricultural Bale Wrap Film?

Agricultural bale wrap film—also called silage wrap film, hay bale film, or agricultural stretch film— is a high-performance polyethylene film used to wrap silage, grass, alfalfa, corn stalks, and hay bales. The primary function of bale wrap is to:

- Create an airtight environment for anaerobic fermentation

- Prevent moisture infiltration and spoilage

- Protect forage from UV, rain, and mechanical damage

- Extend storage time and preserve nutritional value

DERFLEX bale wrap film is engineered to meet the needs of modern mechanized agriculture, supporting both round bale wrapping machines and square bale wrapping equipment.

Key Features of DERFLEX Agricultural Bale Wrap Film

1. Multi-Layer Co-Extrusion Technology (3–7 Layers)

DERFLEX uses advanced 3–7 layer co-extrusion machines to produce film with:

- Better elongation and elasticity

- Stronger tear resistance

- Higher puncture tolerance

- Smoother surface for consistent wrapping

2. Excellent Oxygen Barrier

Our film provides an airtight seal to support anaerobic fermentation, ensuring:

- Reduced nutrient loss

- Controlled fermentation

- Improved silage quality

3. UV Stabilized for 12–24 Months

DERFLEX bale wrap film contains UV stabilizers suitable for long-term outdoor storage in:

- Hot climates

- Cold weather

- Rainy & humid regions

4. High Stickiness & Self-Adhesion

The film layers bond tightly during wrapping, ensuring uniform sealing without adhesive residue.

5. Puncture & Tear Resistant

The film resists damage from:

- Sharp grass stems

- Handling and transportation

- Animal movement

6. Environmentally Friendly Material

Our agricultural bale wrap film is recyclable and meets global agricultural packaging standards.

Applications of Agricultural Bale Wrap Film

DERFLEX bale wrap film is widely used in:

Silage Storage

- Corn silage

- Grass silage

- Oat, ryegrass, alfalfa

Hay & Straw Packaging

- Round hay bales

- Square straw bales

Animal Feed Preservation

- Dairy cattle feed

- Beef cattle feed

- Sheep and goat forage

Outdoor Agricultural Storage

With its UV resistance, DERFLEX agricultural bale wrap film is suitable for long-term outdoor exposure.

Technical Specifications

| Item | Specification |

|---|---|

| Material | LLDPE (Linear Low-Density Polyethylene) |

| Production Method | 3–7 Layer Co-Extrusion |

| Thickness | 25–30 microns (25um standard) |

| Width | 250mm / 500mm / 750mm |

| Length | 1500m / 1800m / 2000m |

| Color | White / Black / Green / Custom |

| UV Resistance | 12–24 months |

| Stretch Ratio | 300%–450% |

| Oxygen Protection | High-level airtight performance |

| Core | 3" paper or plastic core |

Why Choose DERFLEX as Your Agricultural Bale Wrap Film Supplier?

1. 20+ Years Manufacturing Experience

DERFLEX has been producing industrial polymer films and agricultural packaging materials since 2001.

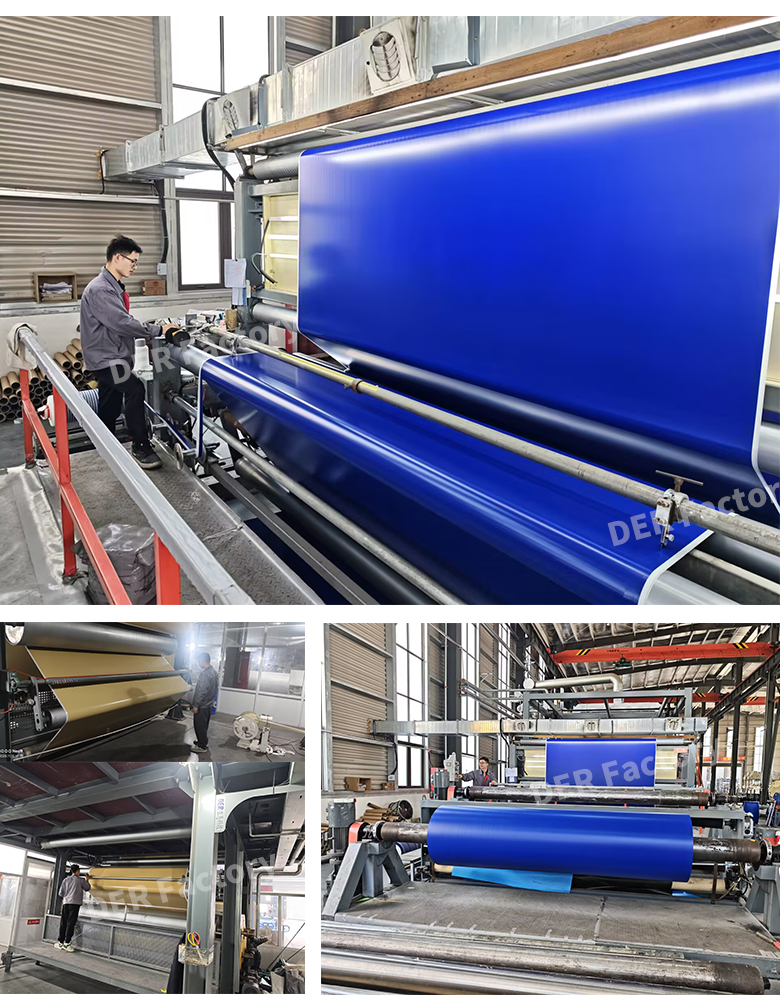

2. Advanced Co-Extrusion Equipment

- 3–7 layer blown film lines

- Fully automatic core loading systems

- Online thickness measuring equipment

- High-speed winding machines

3. Strict Quality Control

- Raw material inspection

- Elongation & tensile strength testing

- UV-aging chamber testing

- Puncture & tear resistance testing

4. Customized Production Options

- Custom colors

- Customized stretch ratio

- Private label bale wrap

- OEM & ODM packaging

5. Global Supply & Export Capability

We supply bale wrap film to farms, distributors, agricultural equipment manufacturers, and wholesalers across Europe, the United States, Australia, South America, and Asia.

How to Use Agricultural Bale Wrap Film Correctly

1. Proper Pre-Stretch

Ensure the wrapping machine is calibrated to achieve uniform stretch (300–450%).

2. Correct Number of Layers

Use **4–6 layers** depending on climate, crop type, and storage duration.

3. Avoid Film Damage

Inspect bales for sharp stones or sticks that may puncture the film.

4. Proper Storage Conditions

- Keep wrapped bales away from birds and rodents

- Place bales on flat, well-drained ground

- Avoid direct contact with sharp tools

FAQ – Agricultural Bale Wrap Film

1. How many layers of wrap should I use for silage?

We recommend 4–6 layers depending on bale type and storage time. More layers ensure better anaerobic fermentation and reduce spoilage risk.

2. What colors are available?

White (best for hot climates), black (high UV resistance), green (general use), and custom colors.

3. How long can wrapped bales be stored?

Up to 12–24 months outdoors with DERFLEX UV-stabilized film.

4. Is DERFLEX bale wrap recyclable?

Yes, our film uses recyclable LLDPE materials.

5. Can I request OEM printed packaging?

Yes. DERFLEX provides private-label and custom packaging service for distributors and brands.