Why Tarpaulin Is an Essential Material for Modern Industries

Why Tarpaulin Is an Essential Material for Modern Industries

From logistics to agriculture and construction, tarpaulin has become one of the most indispensable industrial materials. Explore how PVC, PE, and HDPE tarpaulins are reshaping industrial operations with their durability, waterproofing, and versatility.

Introduction — The Universal Role of Tarpaulin

Tarpaulin (or “tarp”) is a flexible, high-strength fabric used for protection, covering, and containment across a wide range of industries. Available in various materials such as PVC (Polyvinyl Chloride), PE (Polyethylene), and HDPE (High-Density Polyethylene), tarpaulins serve as an all-weather barrier that safeguards equipment, goods, and structures from moisture, UV radiation, and mechanical damage.

In modern industries, tarpaulin materials are preferred due to their affordability, long service life, and adaptability. Leading manufacturers like DERFLEX provide custom-engineered tarpaulins designed to meet the demanding needs of industrial applications worldwide.

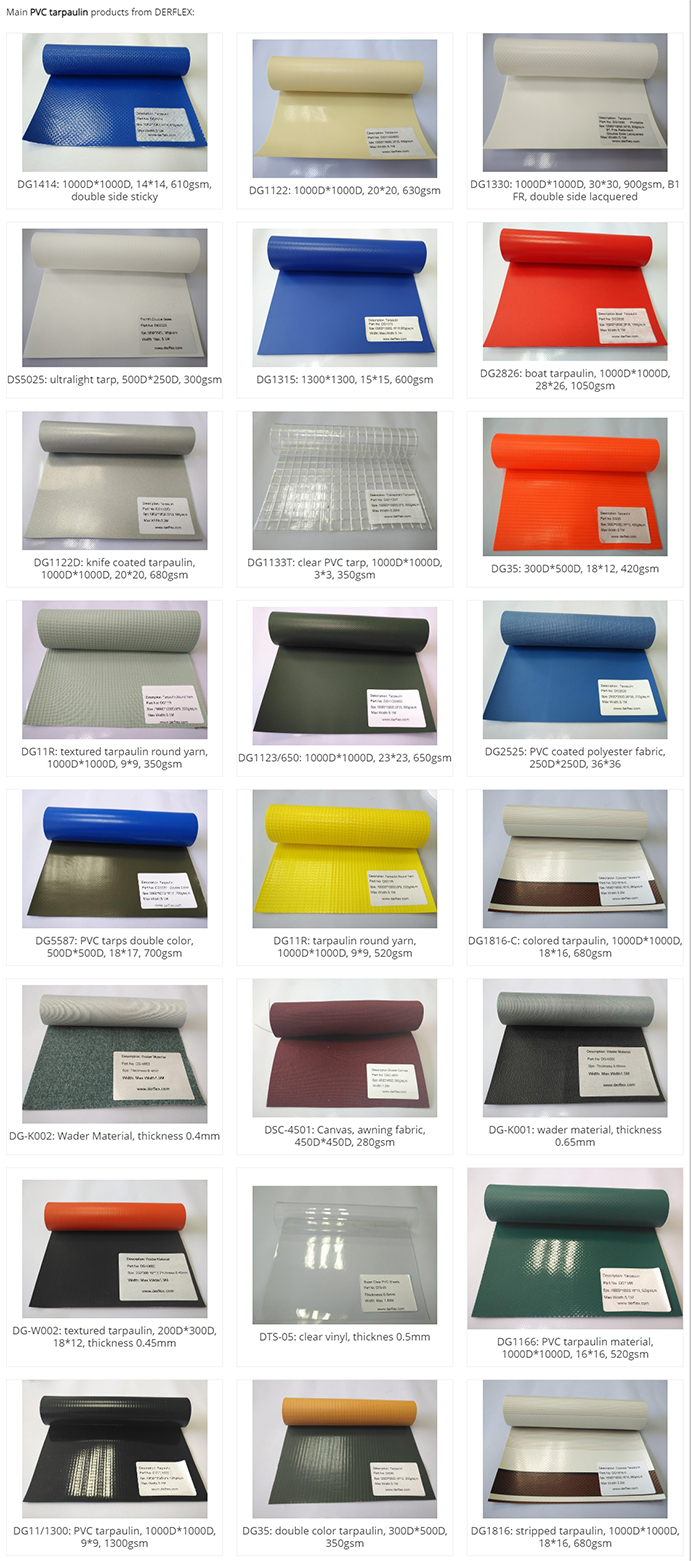

Product Introduction — Types of Industrial Tarpaulin

1. PVC Coated Tarpaulin

PVC tarpaulin is made from polyester fabric coated with polyvinyl chloride. It is known for high strength, flame retardancy, and excellent waterproofing, ideal for outdoor industrial applications.

| Material | PVC coated polyester fabric |

|---|---|

| Weight | 300–1200 gsm |

| Thickness | 0.35–1.2 mm |

| Features | UV resistant, fire retardant, durable, weldable, printable |

| Applications | Truck side curtains, tents, industrial covers, swimming pool liners |

2. PE Laminated Tarpaulin

Lightweight and cost-effective, PE tarpaulin is suitable for short- to medium-term protection applications. It’s often used in agriculture and temporary shelters.

| Material | Woven HDPE with LDPE lamination |

|---|---|

| Weight | 60–250 gsm |

| Features | Waterproof, UV stabilized, flexible, cost-effective |

| Applications | Ground covers, grain storage, temporary roofing, emergency shelters |

3. HDPE Woven Tarpaulin

HDPE tarpaulin is stronger than PE tarps, offering superior resistance to tearing and UV degradation. It is ideal for heavy-duty and outdoor applications.

| Material | High-density polyethylene woven fabric |

|---|---|

| Weight | 150–400 gsm |

| Features | Lightweight, strong, UV treated, high tensile strength |

| Applications | Truck covers, pond liners, scaffolding sheets, construction wraps |

Product Features

- Waterproof and UV Resistant: Protects materials from sunlight and rain in outdoor environments.

- High Strength & Tear Resistance: Designed to withstand mechanical stress and wind loads.

- Temperature Tolerance: Performs effectively under -30°C to +70°C conditions.

- Customizable: Available in different colors, widths (up to 5.1 m), and GSM ranges.

- Printable Surface: Perfect for advertising or branding applications.

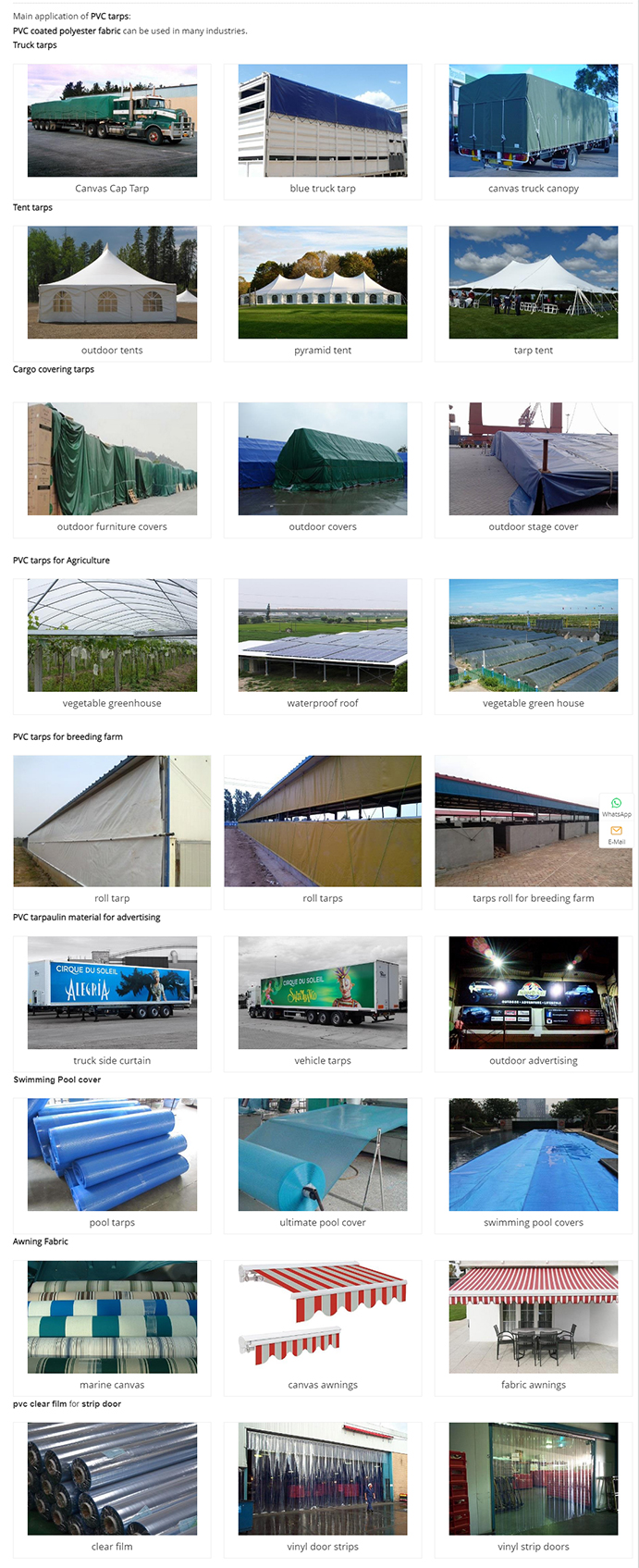

Product Applications — Where Tarpaulin Makes a Difference

- Transportation & Logistics: Cargo covers, truck tarps, and container liners ensure goods stay safe and dry.

- Construction & Infrastructure: Used as scaffolding covers, temporary roofs, and site enclosures to protect from debris and rain.

- Agriculture & Farming: Grain covers, pond liners, greenhouse shading, and silage sheets preserve crops and materials.

- Industrial Warehousing: Equipment and pallet covers prevent corrosion and dust accumulation.

- Recreational Use: Event tents, awnings, and outdoor flooring for camping and exhibitions.

DERFLEX Company Profile

Anhui DER New Material Co., Ltd. (DERFLEX) is one of China’s top manufacturers of PVC coated tarpaulin, PE laminated tarpaulin, and industrial fabric. With more than 20 years of experience, DERFLEX delivers reliable, eco-friendly, and customizable tarpaulin products for global clients.

- Founded: 2001

- Production Area: 30,000+ m² with multiple coating lines

- Exported to 120+ countries worldwide

- Certifications: ISO 9001:2015, REACH, RoHS, SGS UV Test

Installation Precautions

- Clean and dry the surface before installation.

- Do not over-stretch or expose to sharp edges during setup.

- Secure with reinforced eyelets or ropes to avoid tearing in strong winds.

- Clean periodically with mild soap and water — avoid chemical solvents.

- Store rolled and covered when not in use for extended lifespan.

Sold to Countries

DERFLEX tarpaulin products are exported to North America, Europe, South America, the Middle East, Africa, and Asia. Trusted by clients in over 120 countries, DERFLEX continues to supply high-quality tarpaulin solutions for industrial and commercial applications worldwide.

FAQs — Common Questions About Industrial Tarpaulin

Q1: Why is tarpaulin considered essential in modern industries?

A: Tarpaulin’s versatility, durability, and weather resistance make it a critical material for protecting assets, improving logistics, and reducing maintenance costs.

Q2: What’s the difference between PVC and PE tarpaulin?

A: PVC tarpaulin is more durable and fire-retardant, ideal for long-term use. PE tarpaulin is lighter and more cost-effective for temporary or agricultural use.

Q3: Can DERFLEX customize tarpaulin size and color?

A: Yes. DERFLEX offers full customization in dimensions, colors, GSM, and coatings to fit specific industrial needs.

Q4: Are DERFLEX tarpaulins environmentally friendly?

A: Yes. DERFLEX complies with REACH and RoHS standards, offering eco-friendly and recyclable materials.

Q5: How do I request samples or a quotation?

A: Visit our online quote page: Request A Quote for free samples or product specifications.

Relevant Keywords & Long-Tail Phrases

Why tarpaulin is an essential material for modern industries, industrial tarpaulin manufacturer, heavy duty waterproof tarpaulin, PVC tarpaulin applications, PE vs HDPE tarpaulin, tarpaulin fabric for construction, industrial tarpaulin cover, waterproof tarpaulin for trucks, tarpaulin factory China, DERFLEX tarpaulin supplier.

Request A Quote