PVC Coated Fabrics Manufacturer & Industrial Coated Textile Supplier

DERFLEX is a leading manufacturer of PVC coated fabrics with more than 20 years of production experience. As a top-ranking industrial coated textile supplier in China, we focus on producing high-strength, weather-resistant, flame-retardant, waterproof, and UV-resistant PVC coated fabrics designed for global industries including transportation, construction, advertising, marine, outdoor shelters, environmental protection, and agriculture.

Our PVC coated fabrics are widely used in truck covers, tents, awnings, inflatable products, oil booms, industrial machine covers, warehouse membranes, and heavy-duty tarpaulin solutions. With stable quality, competitive price, and global export service, DERFLEX has become a trusted partner for distributors, brand owners, fabric converters, and large engineering contractors in 100+ countries.

What Are PVC Coated Fabrics?

PVC coated fabric is produced by applying high-quality polyvinyl chloride (PVC) coating onto polyester woven fabric through knife-coating or lamination processes. This creates a strong composite material that offers excellent durability, waterproofing, tear resistance, chemical resistance, and weather protection.

Compared with PE or laminated fabrics, PVC coated fabrics deliver better long-term performance and are suitable for demanding industrial environments. DERFLEX provides a full range of specifications from 300gsm to 1500gsm, customized colors, special surface treatments, and tailored coating formulations.

Key Features of DERFLEX PVC Coated Fabrics

- 100% waterproof and leak-proof with strong surface bonding

- Excellent UV resistance designed for long-term outdoor exposure

- Flame retardant options (B1/B2/FR standards)

- High tensile and tear strength suitable for industrial usage

- Anti-mildew and anti-fungal treatment

- Cold-resistant / heat-resistant grades available

- Long service life (3–10 years depending on grade)

- Stable coating thickness using advanced knife-coating line

- Eco-friendly and RoHS compliant

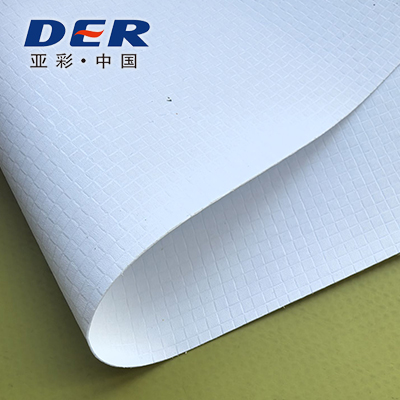

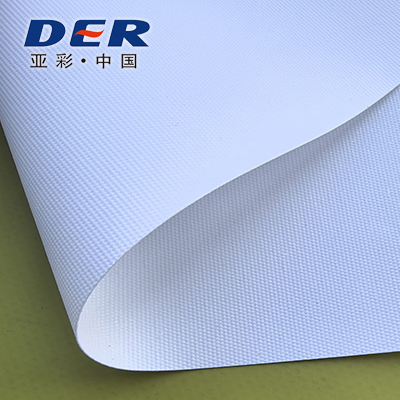

- Available in glossy, matte, embossed, or customized texture

Types of PVC Coated Fabrics We Supply

DERFLEX offers a complete product portfolio to meet different industry requirements.

1. Heavy Duty PVC Coated Fabric

Designed for industrial-grade applications with superior tear resistance and long endurance.

2. Knife-Coated PVC Fabric

Produced by our advanced knife-coating line with excellent uniformity and strength.

3. Flame Retardant PVC Coated Fabric

Certified FR fabric meeting international fire safety standards.

4. UV Resistant PVC Fabric

Special UV absorber formula for long-term sunlight exposure.

5. Anti-Mildew PVC Fabric

Suitable for humid environments, warehouses, marine, and tropical regions.

6. Tent & Awning PVC Fabric

Flexible, weatherproof, and color-stable material for commercial tents and awnings.

7. Inflatable PVC Boat Fabric

Strong adhesion, anti-piercing, and flexible for inflatable structures and boats.

Applications of PVC Coated Fabrics

Our coated fabrics are developed for multi-industry use:

- Truck & trailer covers

- Industrial tarpaulin manufacturing

- Commercial tents and event canopies

- Inflatable boats and inflatable structures

- Construction site protection

- Awning materials

- Oil boom containment systems

- Warehouse and industrial machine covers

- Advertising structures and outdoor displays

- Agricultural shelters and greenhouse coverings

PVC Coated Fabric Specifications

| Item | Specification |

|---|---|

| Material | 100% PVC coated polyester |

| Weight | 300–1500gsm available |

| Base Fabric | 500D–1300D polyester |

| Width | 1.0m–3.2m (custom width available) |

| Surface | Glossy / Matte / Embossed / Customized |

| Temperature Resistance | -30℃ to +70℃ |

| Flame Retardancy | Optional (B1/B2/FR) |

| Colors | White, blue, red, green, yellow, black, and custom colors |

| Applications | Truck covers, tents, awnings, tarps, industrial covers |

Why Choose DERFLEX as Your PVC Coated Fabrics Manufacturer?

- 20+ years manufacturing experience

- Advanced knife-coating and lamination lines

- Global export to 100+ countries

- Strict quality control & test reports

- Custom colors, widths, GSM, and coatings

- OEM/ODM service

- Fast delivery and stable supply capacity

- Professional technical support

DERFLEX Company Profile

DERFLEX is a professional manufacturer of PVC tarpaulin, coated fabrics, printing materials, industrial protection fabrics, and technical textiles. Our factory is equipped with advanced coating lines, lamination machines, and laboratory testing equipment to ensure consistent quality and international standards. With strong R&D capability and stable production capacity, we serve customers in logistics, construction, agriculture, advertising, marine, and environmental protection industries.

Certificates

- ISO9001 Quality Management

- REACH / RoHS Compliance

- MSDS Safety Data

- Flame Retardant Test Reports

- Tensile Strength & Peel Strength Reports

Contact Us for PVC Coated Fabric Solutions

If you are looking for a reliable PVC coated fabrics manufacturer, DERFLEX is your best partner. Contact our sales team for samples, quotations, and technical support.

Email: sales@derflex.com