PVC Membrane – Waterproofing, Roofing & Industrial Protection Solutions

DERFLEX is a leading manufacturer of PVC membrane engineered for long-term durability, UV stability, chemical resistance, and waterproof performance. Our membranes are widely used in construction, roofing, agriculture, environmental engineering, industrial equipment protection, pond lining, and numerous custom applications requiring high-strength flexible materials.

PVC Membrane Product Overview

The DERFLEX PVC membrane is manufactured using premium-grade polyvinyl chloride combined with plasticizers, stabilizers, reinforcement layers (optional), and specialized additives that enhance mechanical strength, UV resistance, anti-aging performance, and overall service life.

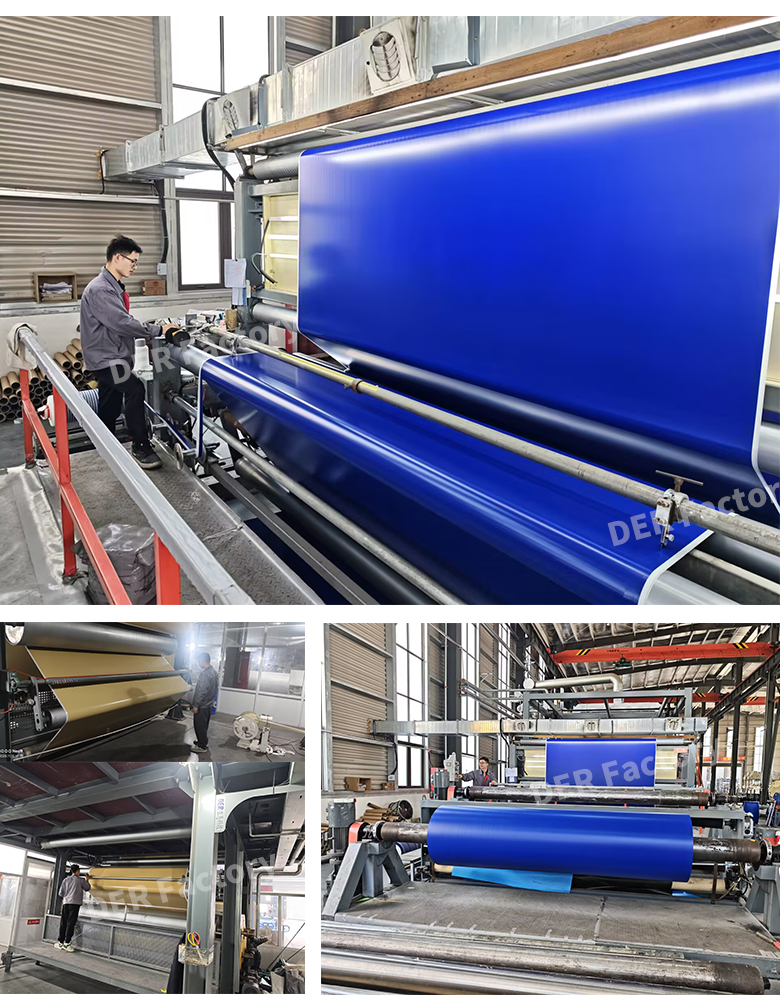

Our production facility uses advanced calendering, coating, knife-coating, and lamination technology, ensuring stable quality, uniform thickness, high tensile strength, and excellent dimensional stability. DERFLEX membranes are engineered for outdoor and indoor use under extreme environments including high UV exposure, chemical contact, moisture, saline water, temperature fluctuations, and high mechanical stress.

Whether for waterproofing, structural roofing, pond construction, environmental engineering, agriculture, or industrial applications, DERFLEX provides tailored solutions with optional reinforcement, flame-retardant grades, anti-fungal treatments, geomembrane structures, and custom colors.

Main Features of DERFLEX PVC Membrane

1. Superior Waterproofing Performance

PVC membrane is inherently waterproof due to its dense molecular structure. DERFLEX enhances this by applying thick coatings and tight polymer bonding technology. The membrane maintains 100% waterproof integrity even under long-term immersion, hydrostatic pressure, or continuous rain exposure.

2. UV and Weather Resistance

UV radiation and long-term outdoor exposure are the primary causes of material degradation. DERFLEX PVC membranes are treated with UV stabilizers, ensuring:

- 15+ years outdoor service life

- Resistance to cracking, brittleness, and surface chalking

- Color retention even under direct sunlight

3. High Tensile Strength & Dimensional Stability

Reinforced PVC membranes come with high-tenacity polyester mesh, ensuring exceptional tear strength, puncture resistance, and long-term load-bearing performance. The membrane remains dimensionally stable even under temperature fluctuations.

4. Chemical, Acid & Alkali Resistance

Suitable for industrial, agricultural, and wastewater engineering environments. The membrane resists:

- Acidic solutions

- Alkaline environments

- Saline water

- Organic chemicals (depending on grade)

5. Anti-Microbial & Anti-Fungal Properties

Special additives prevent microbial growth, mold formation, and material degradation in humid or pond-related applications.

6. Flexible and Easy to Weld

DERFLEX PVC membranes can be welded using high-frequency welding, hot air welding, or chemical bonding, ensuring smooth installation and seamless results.

7. Custom Colors, Thickness & Surface Finish

Available options:

- Thickness: 0.3mm – 2.0mm

- Colors: white, grey, blue, black, transparent, and custom colors

- Surface: smooth, matte, glossy, embossed, or textured

PVC Membrane Specifications

| Property | Value |

|---|---|

| Thickness | 0.3mm – 2.0mm (customizable) |

| Width | 1.02m / 1.27m / 1.52m / 2.05m / custom |

| Length | 50m – 200m per roll (custom) |

| Reinforcement | Optional polyester mesh |

| Surface Finish | Matte / Glossy / Embossed / Smooth |

| Tensile Strength | 1800–3000 N/5cm |

| Tear Strength | 200–450 N |

| Temperature Resistance | -30°C to +70°C |

| Flame Retardant Grade | B1 / M2 / NFPA701 (optional) |

| UV Stability | 5–15 years outdoor grade |

Applications of PVC Membrane

PVC membranes are widely used across multiple industries due to their durability, flexibility, and waterproof properties.

1. Roofing and Construction

- PVC roofing membrane

- Flat roof waterproofing

- Tensile structure membrane

- Building façade membranes

- Temporary construction covers

2. Agriculture

- Greenhouse covers

- Agricultural pond liners

- Irrigation water containment

3. Environmental Engineering

- Landfill liners

- Wastewater containment

- Chemical pond lining

4. Industrial Uses

- Machine covers

- Inflatable structures

- Industrial curtains

5. Aquaculture & Pond Construction

- Fish pond liners

- Shrimp pond membranes

- Reinforced geomembranes

About DERFLEX

DERFLEX is one of China’s top manufacturers specializing in PVC coated fabrics, PVC tarpaulins, PVC membranes, and industrial flexible materials for more than 20 years. With advanced coating lines, strict quality control, and global distribution, DERFLEX delivers stable-quality membrane materials to customers in construction, agriculture, marine engineering, environmental protection, industrial manufacturing, and infrastructure development.

Over the years, DERFLEX has established long-term cooperation with distributors and engineering companies across 80+ countries. Our commitment to quality, durability, and custom manufacturing solutions makes DERFLEX a trusted supplier in global markets.

Learn more about our PVC products at DERFLEX official website.

FAQ – PVC Membrane

1. What is PVC membrane used for?

PVC membrane is used for roofing, waterproofing, pond lining, construction, agriculture, and industrial protection.

2. How long does PVC membrane last?

Outdoor-grade PVC membranes can last 10–20 years depending on UV exposure and application environment.

3. Can DERFLEX customize PVC membrane sizes?

Yes. Width, thickness, color, reinforcement, and surface finish can all be customized.

4. Is PVC membrane environmentally friendly?

DERFLEX PVC membranes are RoHS-compliant and manufactured using eco-safe additives.