DER Group was established since 2001, and developed to multi-purpose flexible material enterprise. Our material and production process: PVC calendared film, industrial strength base fabric, Lamination, knife coating, lacquering, welding, hemming, sewing, etc, to establish full production line to meet customer needs.

The company is also committed to the research and development of environmentally friendly materials, having successfully developed environmentally friendly water-based materials. It has also comprehensively upgraded its mining air duct fabrics, using environmentally friendly water-based materials for antistatic surface treatment, ensuring a stable antistatic index of approximately 3*10^6Ω. The company also serves as the lead unit of the National PVC Biogas Materials Group of the Biogas Society of the China Rural Energy Association. Its newly designed bracket-mounted integrated PVC biogas fermenter has also been awarded a patent.

Large-Diameter Spliced Duct Production Line

This production line offers efficient and precise production capabilities, meeting diverse customer needs. Its core advantage lies in its automated control technology, which ensures product stability and reliability while significantly improving production efficiency. Through this advanced equipment, DER Group is committed to providing greater value to its customers.

Top Laminating Technology

This Hot Lamination production line is equipped with advanced laminating equipment, a technological breakthrough that ensures products are more durable and aesthetically pleasing. Automated control ensures that every air duct meets high quality standards.

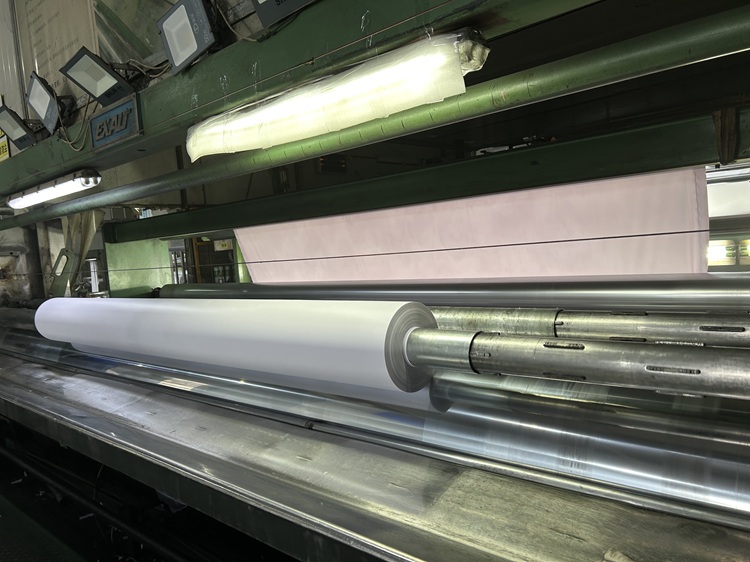

High-End Film-Making Technology

This production line not only incorporates advanced film-making technology but is also equipped with high-end film-making equipment, further enhancing product quality and performance. The precision manufacturing capabilities of these equipment ensure that each air duct exhibits exceptional quality and durability.

Cutting-Edge Base Material Production Equipment

To ensure the exceptional quality and durability of each air duct, we utilize state-of-the-art base material production equipment. These equipment utilizes sophisticated manufacturing processes to create a sturdy and durable foundation for each air duct.

Comprehensive Testing and Inspection Facilities

To ensure comprehensive product quality control, DER Group is equipped with comprehensive testing and inspection equipment. These facilities cover multiple processes, including base fabric production, membrane fabrication, lamination, and automated air duct production. These facilities ensure that every detail meets high standards, ultimately providing stable and reliable products.

Positive pressure air ducts, a core product of the DER Group, boast at least eight distinct advantages. These advantages encompass design, performance, and practicality, making DER positive pressure air ducts unique in the market and highly praised by users. Below, we will explore each of these advantages to provide a more comprehensive understanding of the DER positive pressure air duct's excellence.

Latest EU standard production line and operation system ensures the superior quality of DER air duct fabrics.

The leading automatic air duct welding production line gives DER air ducts exceptional performance.

Innovative design and exquisite craftsmanship distinguish DER air ducts in accessory technology.

Scaled production and processing capabilities provide a solid foundation for DER air ducts.

An extensive sales network demonstrates DER air ducts' high-quality service.

Long-term practice and continuous technological advancement highlight DER air ducts' high cost-effectiveness.

Leading industry standards ensures the safety of DER air ducts.

Deep concern for the occupational health of underground miners embodies the environmental protection concept of DER air ducts.

Data sheet of DER positive pressure ventilation tube:

|

Diameter |

300-1200mm, can be customized |

|

Length |

5M-100M, can be customized |

|

Reverse side size |

15-25cm |

|

Buckle distance |

60cm, 50cm, can be customized |

|

Hanging method |

single hook or double hook |

|

Connection |

Zip or Rings |

|

FR |

M2/B1/NFPA701 |

|

Anti-static |

<3*108Ω |

|

Temperature |

(-25℃)~(+60℃) |

|

100m wind resistance |

≤8N•S2/M8 |

|

Air leakage rate per 100 meters |

≤4.0% |

|

Wind pressure resistance |

≥5000Pa |

Data sheet of DER negative pressure ventilation tube:

|

Diameter |

300-1200mm, can be customized |

|

Length |

5M-100M, can be customized |

|

Reverse side size |

15-25cm |

|

Skeleton wire diameter |

5~8mm |

|

Skeleton spacing |

10~15cm |

|

Buckle distance |

60cm, 50cm, can be customized |

|

Steel rim material |

Spring manganese steel or cold drawn steel |

|

Hanging method |

single hook or double hook |

|

Connection |

Zip or Rings |

|

FR |

M2/B1/NFPA701 |

|

Anti-static |

<3*108Ω |

|

Temperature |

(-25℃)~(+60℃) |

|

100m wind resistance |

Diameter 300mm:N•S2/M8 ≤ 1728.0 Diameter 400mm:N•S2/M8 ≤ 410.0 Diameter 500mm:N•S2/M8 ≤ 134 Diameter 600mm:N•S2/M8 ≤ 54.0 Diameter 800mm:N•S2/M8 ≤ 13.0 Diameter 1000mm:N•S2/M8 ≤ 4.0

|

|

Air leakage rate per 100 meters |

≤4.0% |

|

Wind pressure resistance |

≥5000Pa |

Advantages of Bridge and Roadbed Pre-Compression Water Bags:

Made from high-quality materials, these water bladders offer exceptional durability and aging resistance. This material is not only environmentally friendly and odorless, but also highly impact- and puncture-resistant, ensuring peace of mind and avoiding potential safety hazards during use. Furthermore, its unique design makes installation and removal quick and easy, significantly improving work efficiency.

1) Water Resistance: After being immersed in water, these bags maintain virtually unchanged performance, demonstrating excellent impermeability and stability even under water pressure.

2) Stability:

A. Temperature Stability: This material exhibits excellent temperature stability, preventing flow, blistering, or slipping at high temperatures and cracking at low temperatures. This means it maintains its performance over a range of temperatures.

B. Atmospheric Stability: This material exhibits excellent resistance to aging and corrosion under the combined effects of sunlight, heat, oxygen, and other chemical and microbial agents. 3) Crack Resistance: This material exhibits excellent crack resistance when subjected to load stress and deformation within the allowable range of the building structure, meaning it is not easily broken.

4) Flexibility: For waterproof materials, special emphasis is placed on low-temperature flexibility to ensure ease of construction and prevent brittle cracking.

DER Group ready products advantage:

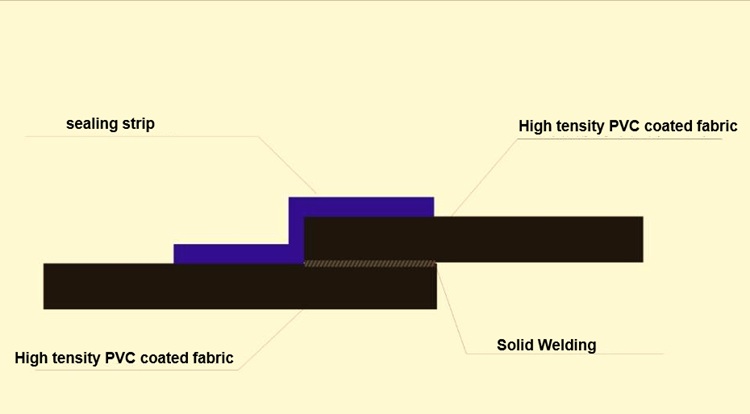

1. Solid Welding and Sealing Technology

During the weld process, we utilize a solid welding process, using hot air pressure to create a tighter bond between the fabrics. This significantly increases the contact surface width of the lap joint, significantly reducing the possibility of leakage. Air pressure testing has shown this technology to have a near-zero permeability, ensuring superior waterproofing.

2. Weld Densification Technology

To further enhance the waterproofing effect, we utilize a weld densification process. At the weld seams, we use high-quality, specially designed sealing strips, which are welded tightly to the fabric using high-temperature welding. This not only enhances the seal but also provides a double guarantee for waterproofing.

3. Innovative Weld Bridge Heat Sealing Technology

Given the complexities of field construction environments, where uneven surfaces often make construction challenging, we have introduced our unique weld bridge flat heat sealing technology. This technology ensures stable welding machine operation and evenly distributes temperature across the weld seam. It effectively avoids quality problems such as uneven welds, wrinkles, and insufficient heat-sealing strength that may be caused by other construction methods, thereby ensuring the durability of the anti-seepage effect.

DER Products are well applied to all industries:

Transportation: truck cover, truck side curtain, vehicle cover, boat cover, inflatable boat, water bladder, …

Outdoor shading: Event tents, medical tents, aircraft hanger, inflatable shelters, outdoor awnings, etc.

Oil Industry: Oil booms, oil container, oil tank, oil bladder, …

Mining industry: Ventilation Tube, air duct, layflat tuble, etc.

Agriculture: Hay Tarp, portable chicken house, etc..

Entertainment: inflatable castle, Water Park, etc.

For more information, pls contact

+8615601786499

www.derflex.com