- tarp

- Frontlit banner

- PVC flex backlit

- Blockout banner

- PVC vinyl sticker

- Tarpaulin

- PVC mesh banner

- PVC preformated vinyl

- Reflective vinyl

- Dye Sublimation fabric

- PVC Stretch Ceiling Film

- Super clear pvc film

- PVC coated fabrics

- TPO coated fabric

- TPU coated fabric

- Automotive Protection Film

- Inkjet media

- Textile banner

- Mesh banners

- New Products

- customized PVC tarps products

- PVC Foam Board Sheet

- Profile download

- Services Hotline

+86-021-54361792 / 54361798 - Email

sales@derflex.com

|

|

Polyethylene tarpaulin

High-quality polyethylene tarpaulin (PE tarpaulin) from DERFLEX — waterproof, UV-stable, tear-resistant PE covers for trucks, agriculture, construction and camping. Product specs, colors, applications, company profile, certificates, installation guidance and FAQs

|

|

||||||||||||||||||||

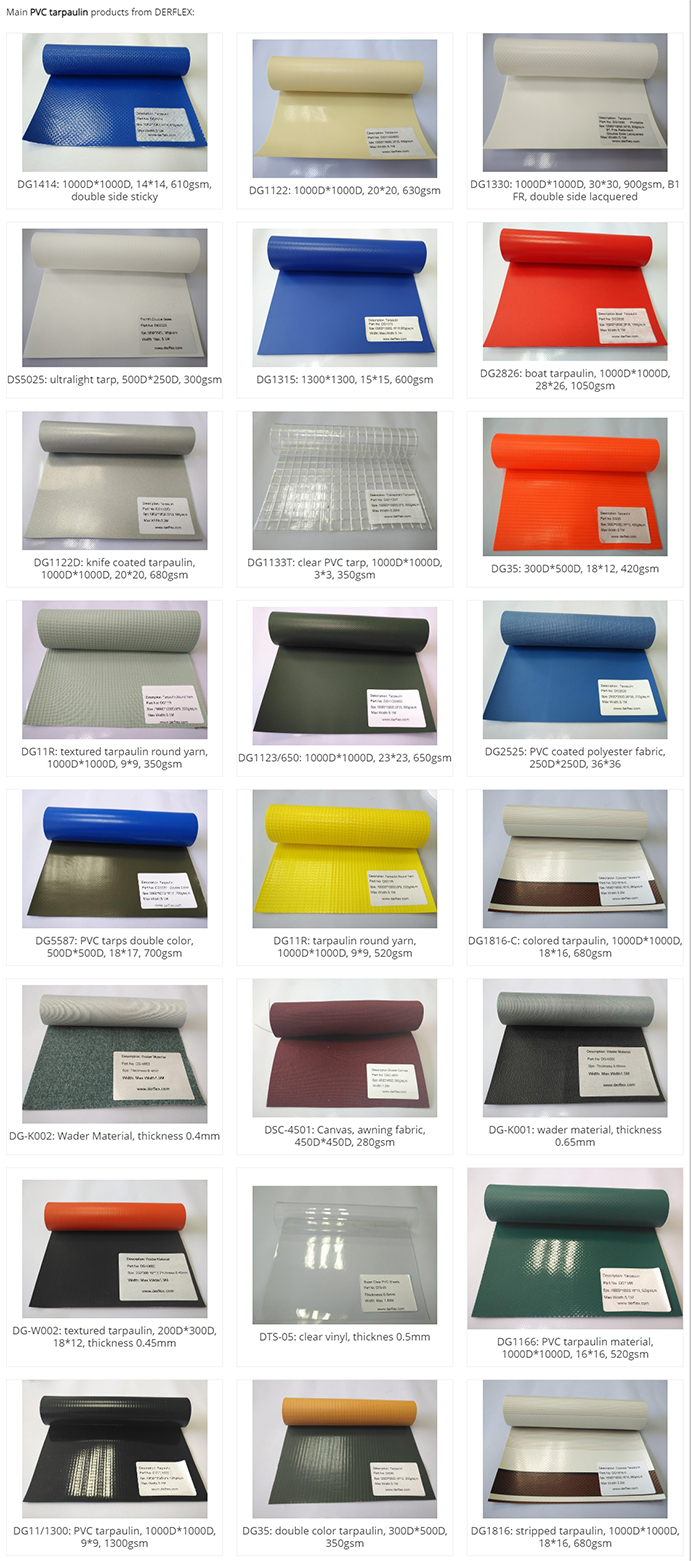

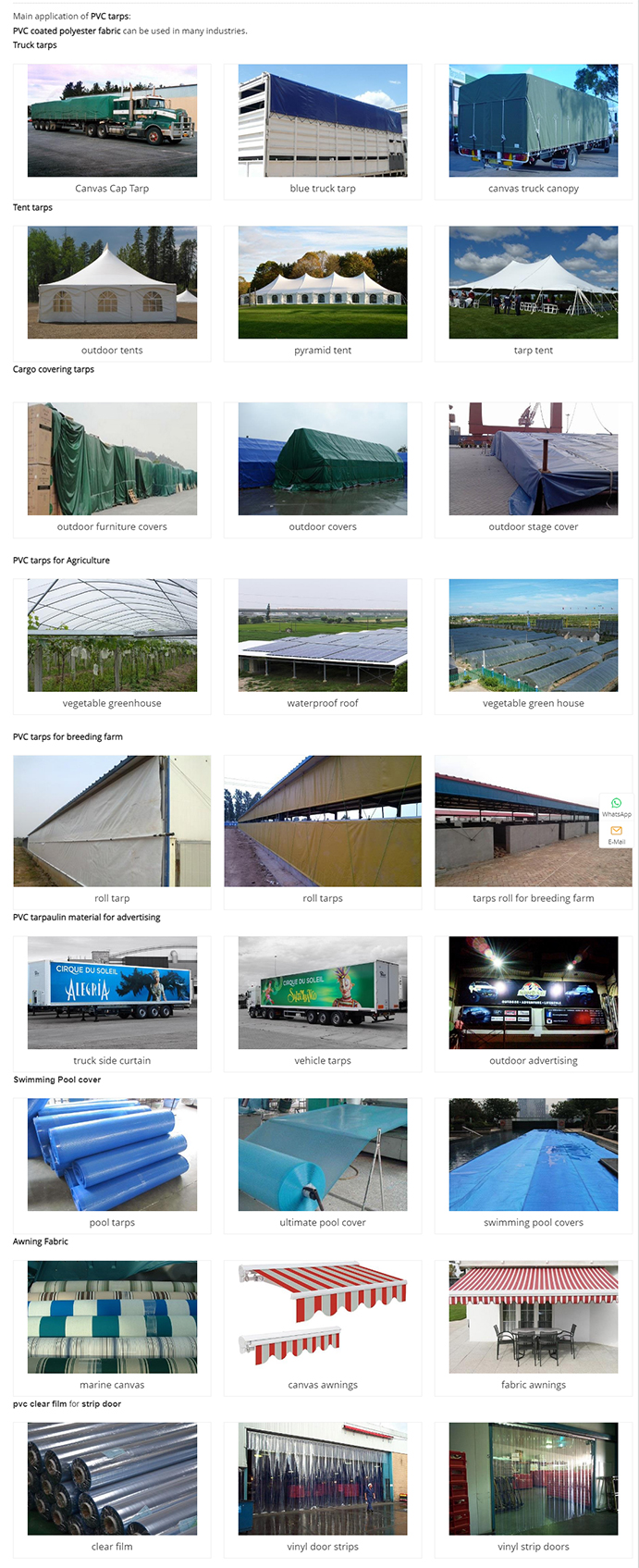

Polyethylene Tarpaulin — Durable PE Tarps for Covers, Storage & TransportMain keyword: polyethylene tarpaulin • Long-tail examples: heavy duty polyethylene tarpaulin, waterproof PE tarpaulin for truck cover, UV resistant PE woven tarpaulin, PE tarp for agricultural storage. Polyethylene tarpaulin (commonly called PE tarpaulin or PE tarp) is one of the most cost-effective and widely used technical covers in the world. Light yet strong, PE tarps are used in applications ranging from temporary roofing, truck covers and ground sheets to agricultural protection, camping and emergency sheltering. DERFLEX’s polyethylene tarpaulins combine reliable raw materials, modern weaving technology and robust finishing so you get a competitively priced tarp without sacrificing performance. Product IntroductionDERFLEX Polyethylene Tarpaulin is manufactured from high-density polyethylene (HDPE) or low-density polyethylene (LDPE) threads woven into a stable fabric, then laminated or coated with protective layers as required. The result is a lightweight waterproof sheet with excellent tear resistance and UV stabilization. PE tarps are normally available in laminated (PE film laminated both sides), reinforced woven, or mesh variants for breathability. Common construction typesProduct Specifications (typical / customizable)DERFLEX supplies polyethylene tarpaulins in multiple standard and custom formats. Typical ranges shown below — final specs are confirmed per order.

Product ColorsPE tarps are commonly color-coded for quick identification and application. DERFLEX standard colors include: Custom color matching is available for large orders to help brand products or match site requirements. Product FeaturesProduct ApplicationsPolyethylene tarpaulin is a multi-purpose material used across many sectors: Anhui DER New Materials — Company ProfileAnhui DER New Materials Co., Ltd. (DERFLEX) is a specialist technical textile and tarpaulin manufacturer with a focus on polymer-coated fabrics, PE and PVC tarpaulins, and laminated industrial materials. With multiple production lines for weaving, lamination and finishing, DERFLEX serves distributors, fabricators and OEM customers worldwide. The company emphasizes quality control, responsive customization and timely export logistics to over 120 countries. Certificates of DERFLEX New MaterialDERFLEX maintains a program of quality assurance and independent testing. Certificates and test reports commonly available include (examples — available on request or provided per order): For projects requiring specific laboratory certification (e.g., flame retardancy, food-contact compliance or marine-grade testing), DERFLEX can arrange third-party tests and provide the registration documents on a per-batch basis. Why Choose UsInstallation Precautions & Best PracticesSold to Countries — Global MarketsDERFLEX polyethylene tarpaulins are exported worldwide. Primary markets include: Use FAQsQ — What is the difference between PE and PVC tarpaulins?A — PE tarps are lighter and more economical; they are excellent for short-to-medium term covers and large area protection. PVC tarpaulins (PVC-coated polyester) are heavier, fully waterproof, more durable, and better for applications requiring frequent use, printing or stronger mechanical performance. Q — How do I choose the right weight (gsm)?A — For quick deployment and temporary use choose 60–150 gsm. For medium-term covers and general transport use consider 150–220 gsm. For heavy-duty or industrial applications choose 220–300 gsm or move to laminated PVC tarpaulins for greater durability. Q — Can PE tarps be repaired in the field?A — Yes. Small tears can be patched with compatible PE film patches and adhesives, or by heat-welding where equipment permits. For emergency fixes, waterproof tape can be used temporarily until a permanent patch or replacement is available. Q — Are PE tarpaulins recyclable?A — Polyethylene is a recyclable thermoplastic. Recycling availability depends on local facilities and whether the tarp is laminated with other non-PE layers. DERFLEX can provide guidance on end-of-life options and reduced-VOC or recyclable formulations on request. Relevant Keywords (SEO)Polyethylene tarpaulin, PE tarpaulin, PE tarp, heavy duty polyethylene tarpaulin, waterproof PE tarpaulin, PE woven tarpaulin, laminated PE tarp, truck cover PE tarp, agricultural polyethylene tarpaulin, PE tarpaulin suppliers, cheap PE tarp wholesale, custom PE tarpaulin manufacturer, DERFLEX PE tarpaulin. Ordering & SamplesFor technical datasheets, sample swatches or a formal quotation, contact DERFLEX via our website: https://www.derflex.com. Provide the required gsm, color, width, and intended application to receive the most relevant recommendation. Generated URL (suggested page slug): — shanghai DER New Materials / DERFLEX Product & Technical Team |

||||||||||||||||||||