- Frontlit banner

- PVC flex backlit

- Blockout banner

- PVC vinyl sticker

- Tarpaulin

- PVC mesh banner

- PVC preformated vinyl

- Reflective vinyl

- Dye Sublimation fabric

- PVC Stretch Ceiling Film

- crystal-clear PVC plastic sheeting

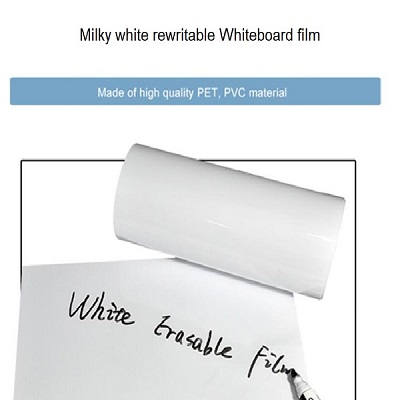

- Inkjet media

- Textile banner

- Mesh banners

- New Products

- customized PVC tarps products

- PVC Foam Board Sheet

- Profile download

- Services Hotline

+86-021-54361792 / 54361798 - Email

sales@derflex.com

|

|

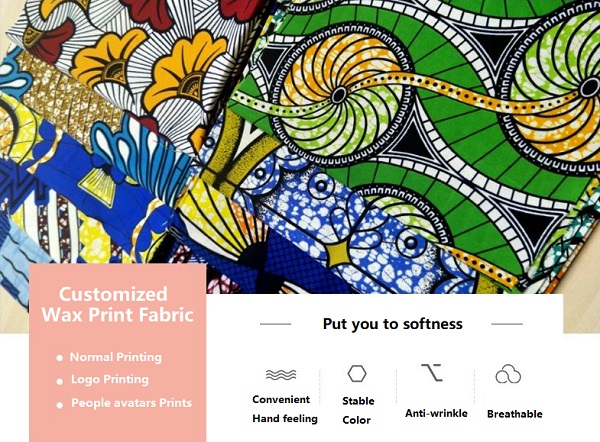

Wax Print Fabrics

Batik cloth fabric is made by waxing, drawing, dyeing, dewaxing and rinsing on the cloth. Because in the process of dyeing, the surface of the waxy white cloth will naturally crack, so that the white cloth will infiltrate the dye and be colored, and there will be many rough or thin irregular color patterns. These patterns are the difference between true and the standard of imitation wax print fabric.

|

|

||||||||||||

|

Batik cloth fabricis made by waxing, drawing, dyeing, dewaxing and rinsing on the cloth. Because in the process of dyeing, the surface of the waxy white cloth will naturally crack, so that the white cloth will infiltrate the dye and be colored, and there will be many rough or thin irregular color patterns. These patterns are the difference between true and the standard of imitation wax print fabric.

Main specifications of African wax print fabric:

Production of batik mud cloth: Pre-waxing process First bleach and wash the self-produced cloth with straw ash, then knead boiled taro into a paste and apply it to the back of the cloth. After drying, use horns to smooth and polish. The slate is a natural ironing table. Waxing Put the white cloth flat on a wooden board or table, put the beeswax in a ceramic bowl or metal pot, melt the wax with charcoal ash or chaff in the brazier, and then use a copper knife to dip the wax. The first step in painting is to operate Location. Dying The method of dip dyeing is to put the painted wax slices in the indigo dyeing vat. Dewaxing After rinsing, then boil it with clean water to remove the wax. After rinsing, the cloth will show clear blue and white patterns.

Advantages:

Main Colors: Also can be customized

Main Applications:

Packing Details

DERFLEX certificates:

DERFLEX is one of the leading wax print fabrics manufacturers in China, with experience over 20 years, production ability over 60 million liner meters per year. If you have more interest, please contact me at Steven Lee Email: steven@derflex.com M.P: +86 15601786499 (WeChat & WhatsApp)

|

||||||||||||