American Tarpaulin — Heavy-Duty PVC Tarps & Custom Solutions

DERFLEX supplies high-performance American tarpaulins engineered for North American climates and applications — truck covers, industrial protection, event tents, and printed advertising tarps. Tailored sizes, certified materials, and robust finishing options ensure long-term performance.

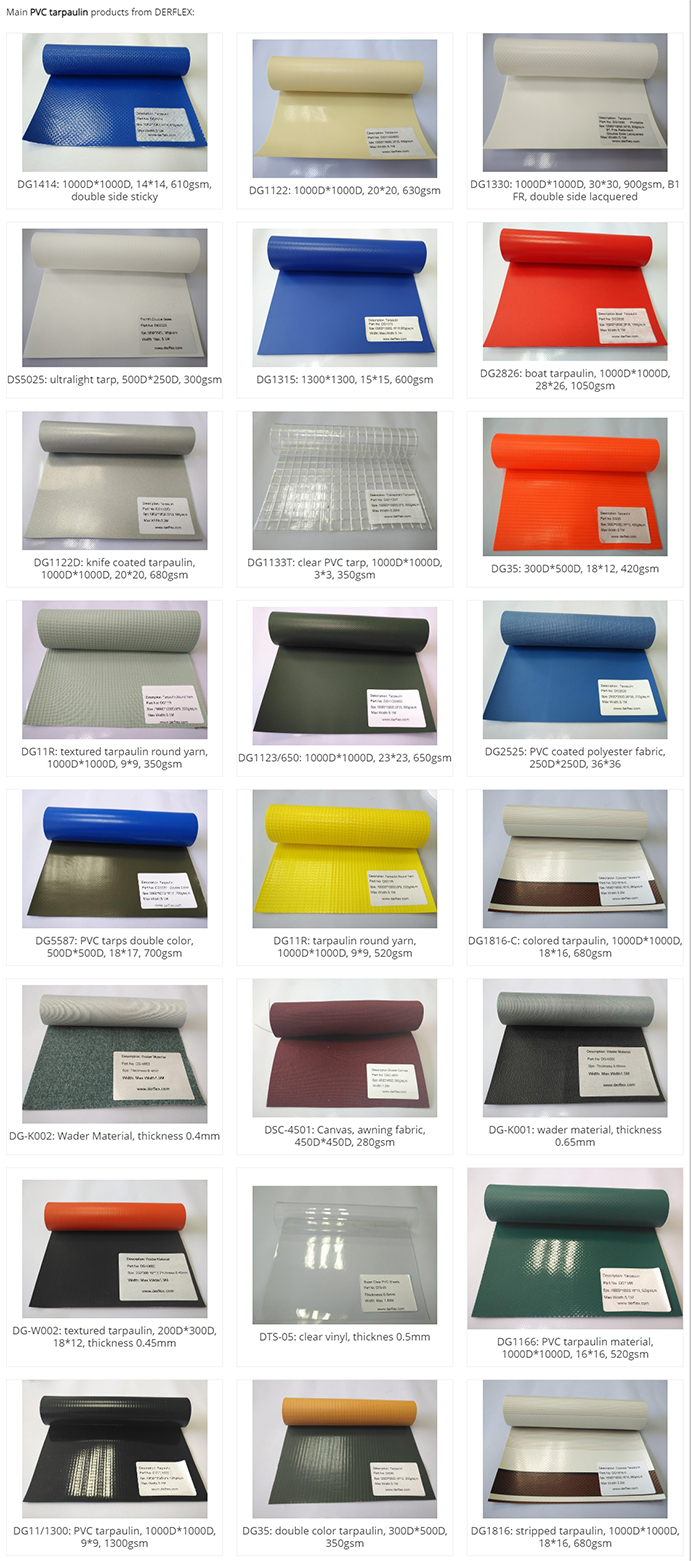

Product Introduction — What is our American tarpaulin?

Our American tarpaulin line brings DERFLEX manufacturing expertise to tarpaulins designed for the United States, Canada and nearby markets. Built around heavy-duty PVC-coated polyester fabrics and reinforced construction, these tarps resist UV, mildew and variable weather while providing excellent tear and puncture resistance. We combine optimized material formulations, wide-format printing capability, certified fire-retardant options and custom finishing (grommets, hems, straps, pockets) to deliver reliable, specification-grade tarpaulins.

Key Features

- Material base: 9x9 – 18x18 polyester scrim + PVC coating or laminated PVC to meet different strength and flexibility needs.

- Gram weights: 350 g/m² up to 1200 g/m² (lightweight to industrial/heavy-duty).

- Weather performance: UV-stabilized, waterproof (100% hydrostatic resistance), mildew-resistant.

- Mechanical strength: high tensile strength, excellent tear resistance, low elongation under load.

- Finishing: double-fold hems, brass/stainless steel grommets, reinforced corners, webbing and ratchet strap pockets.

- Printability: full-bleed digital printing (up to 6-color process), vibrant outdoor inks and lamination for extra durability.

- Optional: flame-retardant treatment certified to NFPA 701 and/or ASTM E84 when required.

Product Specifications & Technical Data

| Item | Typical Specification |

|---|---|

| Product Name | American Tarpaulin — PVC-coated polyester tarpaulins |

| Composition | Polyester woven scrim (500D–1000D) + PVC coating (two-side) or laminated construction |

| Available Grammages | 350g/m² • 450g/m² • 600g/m² • 900g/m² • 1000g/m² • 1200g/m² |

| Thickness | From 0.35 mm (light) to 1.4 mm (heavy) depending on gram weight |

| Roll Widths | 1.5 m • 2.0 m • 2.5 m • 3.2 m • 5.0 m (seamable for wider spans) |

| Tensile Strength (warp/weft) | From 1400 N/5 cm to 4000 N/5 cm (product-dependent) |

| Elongation | Typically 10–25% depending on scrim and coating |

| Hydrostatic Resistance | ≥ 2000 mm H₂O (waterproof standard for heavy-duty tarps) |

| Operating Temp | -40°C to +80°C (-40°F to +176°F) |

| Color & Finish | White, black, blue, green, red, custom printed / matte or glossy finish |

| Fire Rating | Optional NFPA 701 / CPAI-84 / ASTM-certified FR finishes available on request |

| Packaging | Industrial rolls or folded & palletized; protective core and kraft wrapping |

Product Colors & Custom Printing

Standard stock colors include white and blue (commonly used for agricultural and truck covers), black and green for UV-sensitive applications, and red for high-visibility needs. For branding and advertising, we offer full-color digital printing across the tarp face with durable outdoor inks and optional protective lamination to extend print life under harsh sun and abrasion.

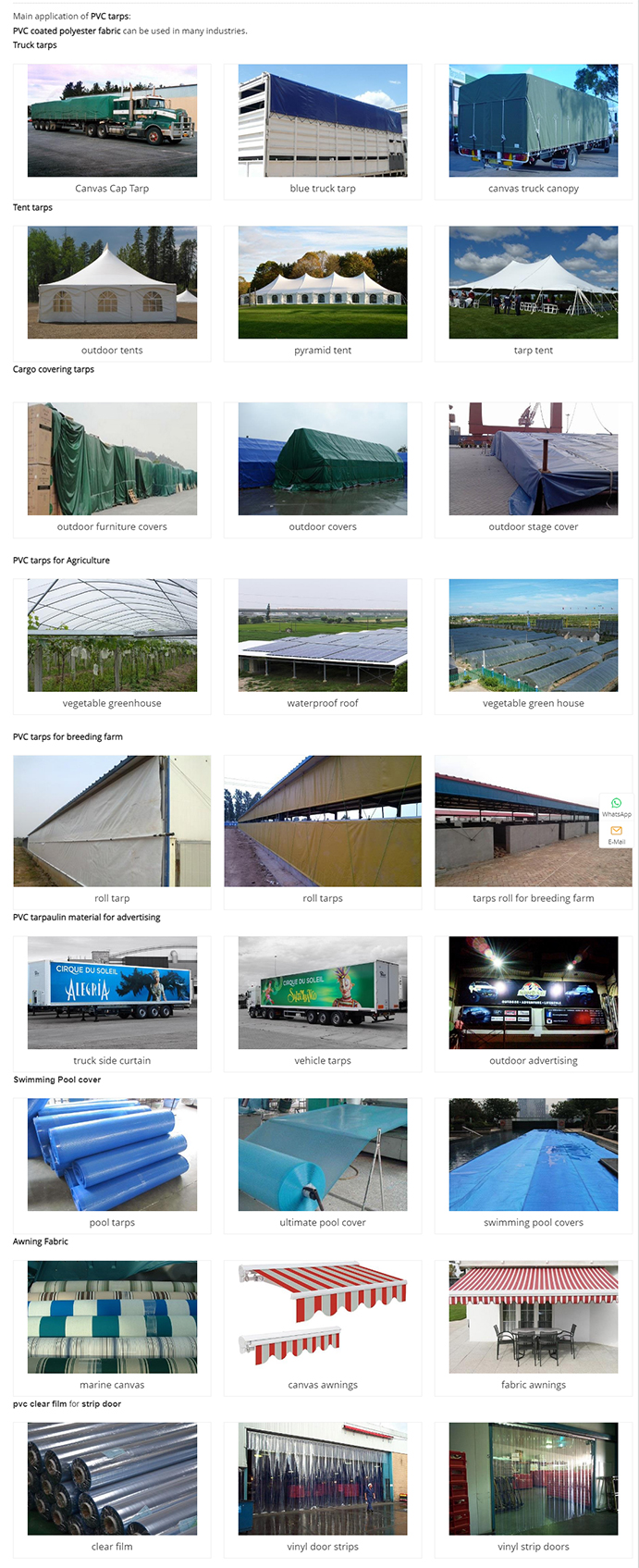

Applications — Where American tarpaulins are used

American tarpaulins are engineered for a wide range of sectors:

- Transportation & Trucking: curtains, flatbed covers, trailer side-walls and roll-up tarps.

- Construction & Infrastructure: site covers, scaffolding wraps, temporary roofing and material protection.

- Agriculture: silage covers, hay and equipment protection.

- Events & Exhibitions: stage covers, tent roofs, event perimeter advertising.

- Industrial & Marine: machine covers, dock curtains, boat covers (with marine-grade options).

- Emergency & Relief: temporary shelter tarps, rapid-deploy covers for disaster response.

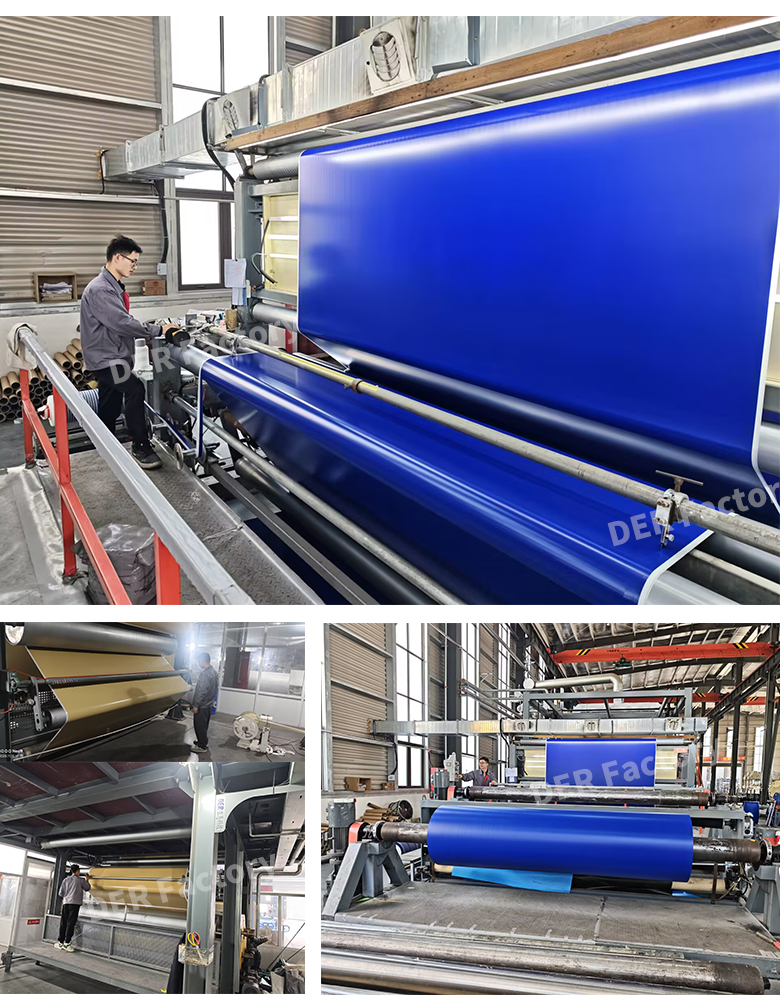

DERFLEX Company Profile

DERFLEX is an international manufacturer of flexible technical textiles and PVC-related products with an emphasis on consistent quality and customized solutions. Our production facilities are equipped to handle small bespoke orders and high-volume roll production with strict quality control under ISO 9001 management systems. We work with clients across supply chains — OEMs, fleet operators, event managers and distributors — delivering reliable tarpaulins and long-term partnerships.

Certifications & Compliance

To ensure compliance with customer and regulatory demands, DERFLEX provides products with the following certifications and test documentation upon request:

- ISO 9001 Quality Management System

- REACH compliance for chemical safety

- NFPA 701 / CPAI-84 / ASTM E84 fire-retardant certification (optional on selected SKUs)

- Tensile, tear and hydrostatic test reports from accredited laboratories

- UV resistance and accelerated weathering test reports

Why Choose DERFLEX for American Tarpaulins?

- Technical expertise: decades of experience in coated fabrics and tarpaulin finishing.

- Customization: cut-to-size, reinforced fittings, printed branding and certified finishes.

- Quality control: batch traceability, mechanical test reports and incoming raw material verification.

- Production flexibility: small-prototype runs to high-capacity manufacturing.

- Logistics & Support: consolidated shipments, drop-shipping and local warehousing options in North America.

Installation & Handling Precautions

To extend service life and ensure safe use, follow these installation and handling best practices:

- Inspect all tarps upon receipt for defects before installation; report any transit damage immediately.

- Always use appropriate reinforcement at load points — webbing, corner plates or gussets — to avoid tear propagation.

- When fastening tarps, distribute load evenly and avoid sharp-edge contact; use protective sleeves where straps contact metal corners.

- For printed tarps, avoid folding along printed ink areas for long-term storage; roll printed surfaces outward or store flat if possible.

- Regularly inspect grommets and hems for wear; replace or re-enforce high-stress areas.

- Do not expose flame sources to tarpaulins unless using certified flame-retardant variants and following local fire codes.

- Clean tarps periodically with mild soap and water; avoid strong solvents that can degrade PVC coatings.

Sold To / Export Markets

DERFLEX exports American tarpaulins globally and supports direct supply and distributor networks in:

- United States

- Canada

- Mexico

- Central & South America (select partners)

- Europe (special orders and warehouse-staged shipments)

- Oceania (Australia, New Zealand — marine-grade variants)

Frequently Asked Questions (FAQs)

- What makes an "American tarpaulin" different from other tarps?

- “American tarpaulin” in our product offering denotes tarps specified and optimized for North American standards and applications — including typical dimensions, commonly required finishes (e.g., NFPA 701 flame-retardant), and logistics options tailored to US/CA supply chains. Material options and fittings are selected to match regional use cases.

- Can you print logos and full-color graphics on tarpaulins?

- Yes. We provide full-bleed digital printing using outdoor-rated inks, with optional protective lamination. Printed tarps are widely used for advertising on trucks, event banners, and building wraps.

- Do you offer fire-retardant certified tarpaulins?

- Yes. Fire-retardant finishes meeting NFPA 701 or other requested standards are available on selected materials. Please request certification documentation as part of your order.

- Are small sample orders available?

- We provide small sample swatches and printed sample panels for approval. Contact our sales team to request samples and lead-time information.

- What is a typical lead time for production?

- Standard production lead time is typically 7–21 working days depending on order size, material selection and printing complexity. Rush production can sometimes be arranged — contact sales for details.

Relevant Keywords for SEO & Search

american tarpaulin, tarpaulin USA, american tarp manufacturer, pvc tarpaulins, custom tarpaulins, truck tarps USA, heavy duty tarps for sale, printed tarpaulin, waterproof tarps USA, flame retardant tarpaulin

Google EEAT — Expertise, Authoritativeness, Trustworthiness

DERFLEX documents technical test reports, third-party lab certificates and project case studies to demonstrate product performance. For procurement and specification processes we provide:

- Traceable test reports for tensile, tear and hydrostatic resistance.

- Certificates of compliance (REACH, ISO 9001 and fire-retardant test certificates where applicable).

- Project references and photographic evidence of installations in North America.

- Technical datasheets and installation manuals available for download to support specification and compliance checks.