Dry Bag Fabric Supplier – High-Performance Waterproof Fabric for Dry Bags

DERFLEX is a professional dry bag fabric supplier with more than 20 years of manufacturing expertise in PVC coated fabric, TPU laminated fabric, and outdoor waterproof technical textiles. Our dry bag fabric offers 100% waterproof protection, high abrasion resistance, strong tear strength, and UV stability, making it ideal for producing all kinds of dry bags, kayaking dry sacks, adventure backpacks, river bags, and marine-grade waterproof gear.

Whether you're sourcing large-volume OEM production or developing a customized dry bag model for your brand, DERFLEX provides durable, reliable, and industry-proven dry bag fabric solutions designed for both commercial and industrial markets.

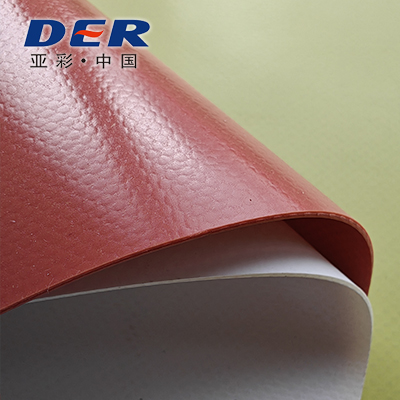

Product Introduction – Premium Dry Bag Fabric Material

As a leading dry bag fabric manufacturer, DERFLEX supplies roll-to-roll waterproof fabric engineered specifically for dry bags. Based on international outdoor gear standards, our materials deliver excellent performance in extreme outdoor environments such as kayaking, rafting, hiking, fishing, marine sports, camping, and snow conditions.

We offer two main categories of waterproof dry bag fabric:

- PVC Dry Bag Fabric – cost-efficient, durable, 100% waterproof, widely used for commercial dry bags.

- TPU Dry Bag Fabric – lightweight, eco-friendly, high flexibility, cold-resistant, suitable for premium outdoor equipment brands.

DERFLEX ensures each batch follows strict QC inspection to guarantee excellent appearance, uniform coating, high peel strength, and long service life.

Product Features – Why DERFLEX Dry Bag Fabric Stands Out

1. 100% Waterproof Protection

Using high-density woven polyester with PVC or TPU coating, our dry bag fabric provides 0 water penetration, even under pressure or long-time immersion.

2. Exceptional Durability

Designed for rugged outdoor environments, our fabric resists abrasion, puncture, tearing, and prolonged use in water, sunlight, or muddy terrains.

3. UV, Cold, and Heat Resistant

Stable performance from -30°C to +70°C. Ideal for winter expeditions, desert conditions, and high-altitude environments.

4. Smooth Surface & Easy Welding

Perfect for HF welding, hot-air welding, and sewing. Suitable for mass production with consistent quality.

5. Customizable Options

Color, thickness, texture, printing, and branding can be fully customized according to your dry bag design.

Product Parameters

| Item | Specification |

|---|---|

| Material Options | PVC Coated Fabric / TPU Laminated Fabric |

| Base Fabric | 500D / 840D / 1000D polyester |

| Weight | 380gsm – 900gsm (customizable) |

| Thickness | 0.35mm – 1.0mm |

| Width | 1.02m / 1.5m / custom width |

| Surface Finish | Glossy / Matte / Embossed / Smooth |

| Waterproof | 100% waterproof, hydrostatic pressure ≥ 6000mmH₂O |

| UV Resistance | ISO 4892 certified |

| Welding Method | Hot-air / HF welding / sewing |

| Application | Dry bags, dry sacks, kayak bags, river bags, waterproof backpacks |

Available Colors

DERFLEX offers customizable colors to match your brand identity:

- Black

- Yellow

- Orange

- Blue

- Army Green

- Red

- Transparent (for TPU)

- Custom Pantone colors

Applications of Dry Bag Fabric

- Outdoor dry bags

- Kayak waterproof bags

- Rafting and river bags

- Waterproof backpacks

- Motorcycle tail bags

- Fishing and marine protective bags

- Snow and winter expedition bags

- Camping dry sacks

DERFLEX Company Profile

Founded in 2001, Shanghai DER New Material Co., Ltd. is a leading global manufacturer of PVC coated fabric, technical textiles, digital printing materials, tarpaulin, and TPU specialty fabrics. With more than 20 years of industry experience, DERFLEX exports to 120+ countries, serving distributors, wholesalers, and outdoor equipment brands worldwide.

We operate advanced production lines including knife coating, calendering, laminating, and TPU lamination, ensuring stable quality and competitive prices.

Certifications

- ISO 9001 Quality Management System

- REACH Compliance

- RoHS Certification

- UV Resistance Testing Report

- Hydrostatic Pressure Waterproof Test

Why Choose DERFLEX as Your Dry Bag Fabric Supplier?

1. 20+ Years Manufacturing Excellence

We supply stable and high-quality outdoor waterproof materials to global brands.

2. Strict Quality Control System

Every roll undergoes thickness, weight, color, coating, and durability inspection.

3. Fast Delivery & Large Inventory

Popular colors and specifications are always in stock for quick shipping.

4. OEM/ODM Support

Fully customizable logo printing, fabric color, thickness, and packaging.

5. Competitive Factory Price

Direct-from-manufacturer pricing without middlemen.

Installation & Processing Precautions

- Use professional hot-air welding equipment for the best seam strength.

- Avoid sharp tools to prevent accidental punctures during cutting.

- Allow fabric to rest 24 hours after welding for maximum adhesion.

- Store the material in a dry environment away from direct sunlight.

- When sewing TPU fabric, use flexible thread suitable for elastic materials.

Sold to 120+ Countries

DERFLEX dry bag fabric is widely exported to:

- USA

- Canada

- Australia

- UK

- Germany

- France

- Russia

- Brazil

- Japan

- Korea

- Thailand

- Singapore

- Middle East & Africa

Dry Bag Fabric FAQs

1. What is the best fabric for dry bags?

PVC coated fabric is best for durability and affordability, while TPU laminated fabric is ideal for lightweight and premium outdoor gear.

2. Can you customize colors?

Yes, DERFLEX supports Pantone color customization.

3. Do you offer OEM dry bag production?

We supply fabric only but can introduce reliable dry bag factories if needed.

4. What is the minimum order quantity?

Moq is normally 1000m per color, but trial orders can be discussed.

5. Do you provide samples?

Yes, free A4-size samples are available upon request.