Heavy-Duty Tarpaulin Fabrics: 650gsm, 1000gsm and Beyond

Heavy-duty tarpaulin fabrics are the backbone of tough outdoor protection — from truck covers and construction scaffolds to industrial shelters and marine uses. Grades such as 650gsm and 1000gsm are industry standards; heavier weights (900–1200gsm and above) address the most demanding environments. This guide from DERFLEX explains material choices, specifications, real-world applications, installation best practices and how to pick the right GSM for your project.

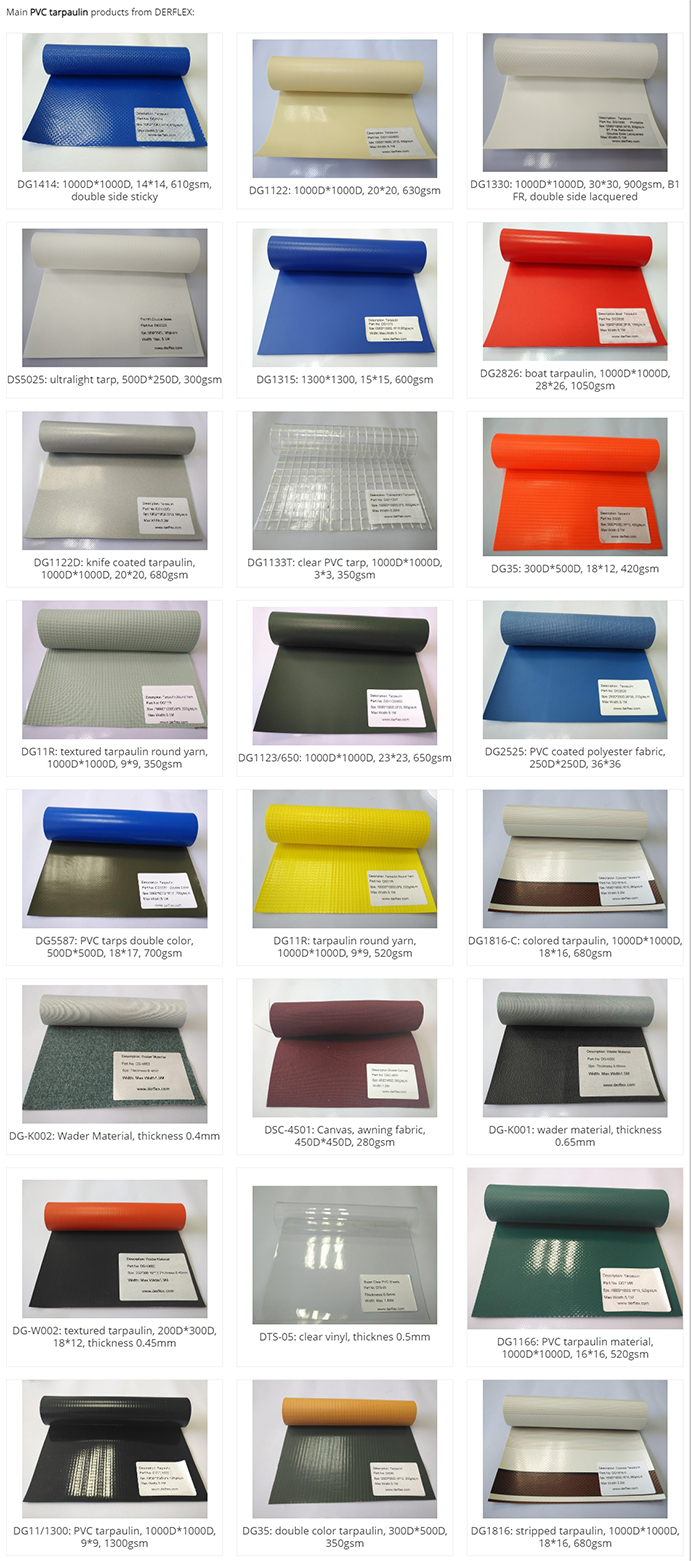

Product Introduction

Heavy-duty tarpaulin fabrics are typically produced from a woven polyester base cloth that is knife-coated or laminated with PVC (polyvinyl chloride) to create a durable, waterproof composite. DERFLEX manufactures a full range of heavy tarpaulin grades — commonly 650gsm, 900gsm, 1000gsm and 1200gsm — available as rolls or converted finished tarps with hems, reinforced corners and grommets. These materials combine high tensile strength, abrasion resistance and weatherproofing suitable for long-term outdoor duty.

When spec'ing tarpaulin fabric, customers consider GSM (weight), base cloth denier (D), coating method, surface finish, and special treatments (UV stabilizers, fire retardant, anti-fungal). Below we break down why each matters and where each grade excels.

Why GSM & Base Cloth Matter

GSM (grams per square meter) is a direct indicator of material mass and generally correlates with toughness and durability. The base cloth denier (e.g., 500D, 1000D) and weave determine tear and tensile resistance. Coating method — knife coating vs. lamination — affects adhesion, flexibility and abrasion performance. DERFLEX heavy-duty tarpaulins use high-tenacity polyester (often 1000D or 1500D) with double-side PVC knife coating for maximum durability.

Product Features (Typical for 650gsm, 1000gsm & Heavier Grades)

- Waterproof & Weatherproof: Full PVC coverage prevents water ingress and resists moisture.

- High Tensile & Tear Strength: Engineered base fabric (1000D+) for heavy load handling.

- Abrasion Resistance: Thick PVC layers resist scraping in rugged environments.

- UV Stabilization: Prolonged outdoor life with reduced color fading and embrittlement.

- Cold Flexibility: Special formulas maintain flexibility in low temperatures (cold-crack resistance).

- Fire-Retardant Options: B1/M2/NFPA701 grades available for event, building or public use.

- Printable / Coatable: Smooth lacquer or PVDF finishes for high-quality digital or screen printing.

- Easy Fabrication: Compatible with hot-air welding, HF welding and mechanical reinforcement.

Product Specifications — Reference Table

| Grade | Typical GSM | Base Cloth | Coating | Typical Uses |

|---|---|---|---|---|

| Medium-Heavy | 650gsm | 1000D polyester | Knife-coated PVC (double side) | Truck covers, mid-size tarps, awnings |

| Heavy | 900–1000gsm | 1000–1500D polyester | Double-sided knife coating | Flatbed tarpaulins, construction covers, scaffolding |

| Extra Heavy / Industrial | 1000–1200gsm+ | 1500D polyester or special weaves | Thick knife coating / reinforced laminate | Mining, marine covers, high-abrasion areas |

Notes: Custom formulations are available — e.g., anti-fungal, anti-static, PVDF topcoat, cold crack formulas down to −40°C, and bespoke colors or printing.

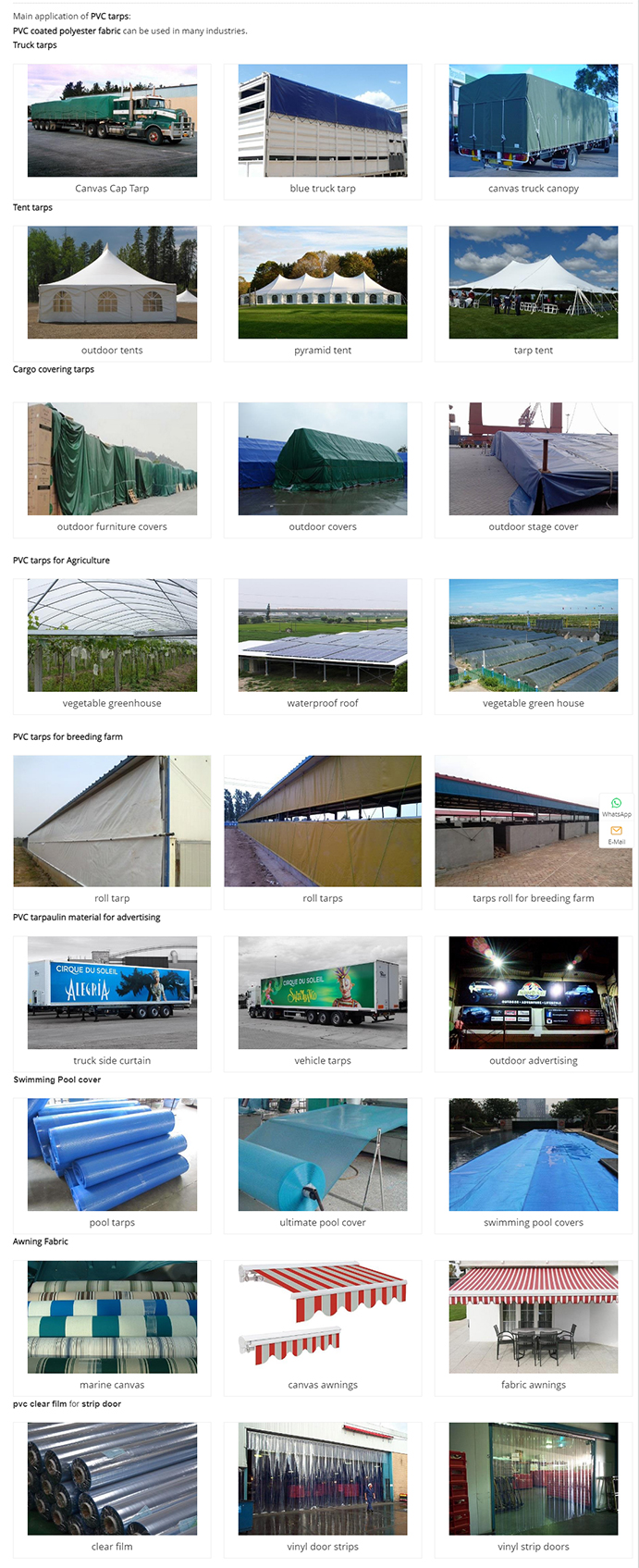

Product Applications — Where Each Grade Shines

650gsm

650gsm tarpaulins balance weight and cost — ideal for truck curtain sides, medium-duty tarps, event covers and storage covers where repeated handling is expected but the absolute heaviest abrasion is not constant.

900–1000gsm

900–1000gsm is the workhorse range for industrial uses: scaffolding wraps, concrete curing sheets, heavy-load truck covers, and temporary roofing. These grades handle higher mechanical stress and resist tearing under tension.

1000–1200gsm and Beyond

When applications demand maximal abrasion resistance and long life (mining, offshore, heavy manufacturing, bulk cargo), 1000–1200gsm and custom heavier grades are recommended. These fabrics are engineered to take repeated abrasion, cutting risk and extended UV exposure.

DERFLEX Company Profile

DERFLEX is a specialist manufacturer of PVC coated and vinyl-coated fabrics with over 20 years of production experience. Our facilities include advanced knife-coating, calendaring and lamination lines, plus in-house testing and QC. We supply heavy-duty tarpaulin rolls and finished covers globally and support OEM/ODM projects — from small custom samples to full container shipments.

Installation & Handling Precautions

- Inspect the surface for sharp edges before deploying tarpaulins. Use protective edge strips where necessary.

- Install with even tension to avoid point loads; use reinforced corners and webbing to distribute stress.

- For seams, prefer hot-air welding or high-frequency (HF) welding to achieve waterproof, durable joins.

- Avoid folding and storing wet — clean, dry and roll the tarp for storage to extend life.

- Use mild soap and water for cleaning; avoid strong solvents that can attack PVC additives.

Sold to Countries — Export & Support

DERFLEX heavy-duty tarpaulins are exported to more than 80 countries worldwide, including the USA, Canada, EU nations, UK, Australia, UAE, Saudi Arabia, Brazil, Chile, South Africa, India and Southeast Asia. We provide export documentation, third-party testing (SGS, BV, Intertek) and customized packaging for international freight.

How to Choose: Simple Selection Checklist

- Identify application: transport, construction, marine, or storage.

- Assess mechanical stress: occasional handling vs. continuous abrasion.

- Select GSM: 650gsm for medium duty; 900–1000gsm for heavy duty; 1000–1200gsm+ for extreme duty.

- Choose coatings/treatments: UV, FR, anti-fungal, cold crack if needed.

- Confirm fabrication method for seams: HF welding for coated materials; hot-air for thick coatings.

FAQs — Frequently Asked Questions

Q: What is the benefit of 1000gsm vs 650gsm tarpaulin?

A: 1000gsm provides substantially higher tear and abrasion resistance, longer life under heavy use and better performance under extreme weather. 650gsm is lighter, more economical and easier to handle for medium-duty tasks.

Q: Can heavy-duty tarpaulin be printed?

A: Yes. DERFLEX offers printable lacquered or PVDF finishes for high-quality digital or screen printing used in advertising and branded fleet covers.

Q: Is fire retardant treatment available for heavy tarps?

A: Yes. We can supply B1, M2, and NFPA701 certified fire-retardant grades suitable for public-use structures and event tents.

Q: What welding method should be used for thick tarpaulins?

A: Hot-air welding is versatile for thick double-coated tarps, while HF welding can give strong seams for certain coated constructions. DERFLEX technical staff can advise based on the exact grade and intended use.

Q: Do you provide samples and test reports?

A: Yes. DERFLEX provides A4 sample pieces for evaluation and can arrange SGS / third-party testing on request for tensile, tear, UV and flame tests.

Relevant Keywords

heavy-duty tarpaulin fabric, 650gsm pvc tarpaulin, 1000gsm pvc coated fabric, 1200gsm tarpaulin, heavy duty PVC tarpaulin roll, industrial tarpaulin fabric, high strength waterproof tarpaulin, derflex tarpaulin manufacturer