- tarp

- Frontlit banner

- PVC flex backlit

- Blockout banner

- PVC vinyl sticker

- Tarpaulin

- PVC mesh banner

- PVC preformated vinyl

- Reflective vinyl

- Dye Sublimation fabric

- PVC Stretch Ceiling Film

- Super clear pvc film

- PVC coated fabrics

- TPO coated fabric

- TPU coated fabric

- Automotive Protection Film

- Inkjet media

- Textile banner

- Mesh banners

- New Products

- customized PVC tarps products

- PVC Foam Board Sheet

- Profile download

- Services Hotline

+86-021-54361792 / 54361798 - Email

sales@derflex.com

|

|

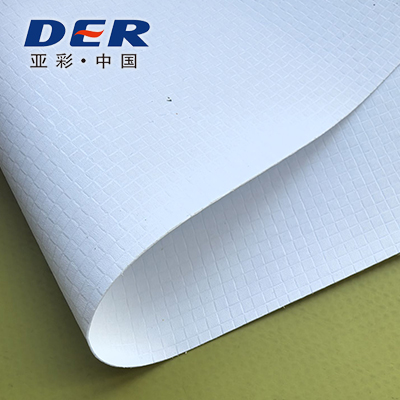

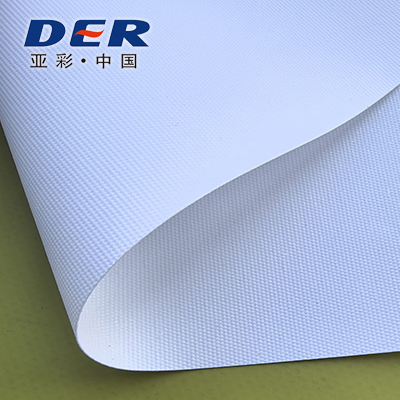

PVC Coated Architectural Fabrics

Derflex is a professional PVC coated architectural fabrics manufacturer and supplier, providing high-performance architectural membrane fabrics for tensile structures, facade shading, canopies, roofs, and large-span buildings.

|

|

||||||||||||||||||||

PVC Coated Architectural Fabrics Manufacturer & SupplierDerflex is a globally recognized PVC coated architectural fabrics manufacturer and supplier, delivering advanced architectural membrane fabric solutions for modern building design. Our PVC coated architectural fabrics are engineered for strength, durability, aesthetics, and long-term outdoor performance, making them ideal for tensile structures, large-span roofs, façade shading systems, and landmark architectural projects. With more than two decades of experience in technical textile manufacturing, Derflex has become a trusted partner for architects, engineers, project developers, and contractors worldwide. Our architectural fabrics combine structural reliability with design flexibility, supporting innovative architectural concepts across commercial, public, and industrial applications. What Are PVC Coated Architectural Fabrics?PVC coated architectural fabrics are high-performance composite materials consisting of a woven polyester base fabric coated with polyvinyl chloride (PVC). This combination provides exceptional tensile strength, dimensional stability, weather resistance, and design versatility. Unlike traditional rigid building materials, architectural fabrics allow lightweight construction, long spans, curved forms, and translucent or opaque surfaces. PVC coating enhances durability while enabling surface treatments such as PVDF or acrylic lacquer for improved self-cleaning and UV resistance. Core CharacteristicsDerflex PVC Coated Architectural Fabric Structure1. Polyester Base FabricThe foundation of Derflex architectural fabrics is a high-tenacity polyester yarn woven into a stable fabric structure. This layer provides the mechanical strength required to withstand tension loads, wind pressure, and structural stress. 2. PVC Coating LayerThe PVC coating encapsulates the polyester fabric, providing waterproofing, weather resistance, and surface uniformity. Advanced coating formulations ensure long-term flexibility without cracking or embrittlement. 3. Surface Treatment (Optional)Optional surface finishes such as PVDF or acrylic lacquer improve self-cleaning properties, chemical resistance, and color stability, particularly for high-profile architectural projects. Key Advantages of PVC Coated Architectural FabricsLightweight Yet StrongPVC coated architectural fabrics offer an exceptional strength-to-weight ratio. This allows for reduced structural steel requirements and lower overall construction costs. Design FreedomArchitectural fabrics enable creative freedom with curved, tensile, and organic forms that are difficult or impossible to achieve using conventional building materials. Weather & UV ResistanceDerflex fabrics are formulated to resist prolonged UV exposure, heavy rain, snow loads, and temperature fluctuations, ensuring reliable performance in diverse climates. Energy EfficiencyDepending on translucency and color, PVC coated architectural fabrics can optimize daylight utilization, reduce heat gain, and improve overall building energy efficiency. Long Service LifeWith proper design and installation, Derflex PVC coated architectural fabrics offer a service life of 15–25 years, making them a cost-effective architectural solution. Technical Specifications

|

||||||||||||||||||||