Overview — Designed For Touring, Leisure & Rental Fleets

Caravan awnings protect occupants and gear from sun, rain and wind while expanding usable living space. Derflex manufactures modular awning systems that range from simple fabric canopies to integrated awning-and-annex solutions compatible with popular awning rails and channel systems used by leading caravan and RV brands.

Who uses Derflex awnings?

- Private caravan & motorhome owners looking for long-lasting shelter solutions.

- Campervan converters and van-life communities requiring lightweight, low-profile canopies.

- Rental companies and holiday parks needing durable, brandable awnings with quick-fit hardware.

- Outdoor event organizers and mobile vendors who require fast-deploy shade systems.

Material Science & Why It Matters

Selecting the correct fabric and construction method is critical for awnings: they must resist UV degradation, shed water, tolerate repetitive folding and resist mildew. Below we map common material choices to performance outcomes.

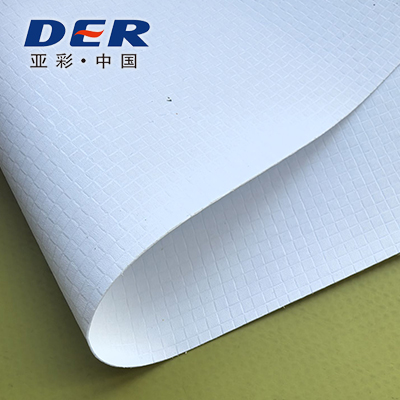

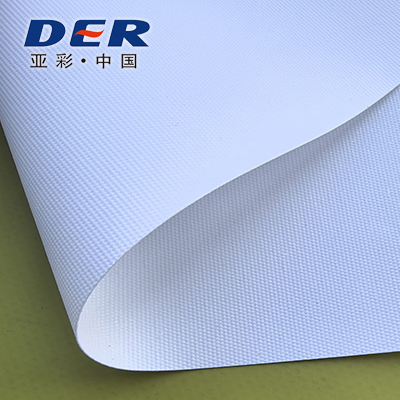

PVC Coated Polyester (High Durability)

PVC-coated polyester fabrics (300–650 gsm) are robust, waterproof and easy to clean. They are ideal for roll-out awnings and annex walls. PVC coatings include UV stabilisers and fungicidal additives to prolong service life in wet climates. Welded seams and thermo-bonded hems provide strong, durable joints for heavy-use installations.

Acrylic Canvas (Breathability & Aesthetics)

Acrylic canvas offers premium aesthetics and breathability, reducing condensation underneath. While not as waterproof as PVC, acrylics are highly fade-resistant and deliver comfort in sunny climates. Typically used for premium valances and decorative coverings.

Lightweight Polyester & Ripstop Blends

For ultralight campervan awnings, modern ripstop polyester laminates balance low pack-weight with resistance to tearing. These fabrics fold compactly and are suitable for touring where load space is limited.

Design Features & Hardware

Our awning systems are designed to be robust yet simple to use. Key features include:

- Quick-release fittings: allow fast assembly and disassembly without specialised tools.

- Wind-lock valves & tie-downs: integrated anchor points and tensioning systems improve wind performance.

- Zip-in annex systems: convert a sun canopy into a fully enclosed living space using zippers and clip rails.

- Retractable mechanisms: optional motorised or manual rollers for compact storage and easy deployment.

- Valance options: standard, branded and printed valances to suit rental fleets or personal style.

Performance, Standards & Testing

Derflex awnings undergo QA testing to ensure they meet expected performance thresholds. Typical tests and standards include tensile strength of fabric (ISO 13934), seam strength and peel resistance, water ingress tests (EN 20811 / hydrostatic head), UV ageing (ISO 4892 QUV), and wind-load simulations where applicable. We also test hardware fatigue for frequent-use scenarios.

Product Range — Models & Use Cases

We manufacture both stock and bespoke models. Below is a representative product family and recommended applications.

| Model |

Type |

Fabric |

Use Case |

Key Features |

| DF-AW-300 |

Compact roll-out |

300 gsm PVC |

Small caravans; weekend touring |

Manual roll, quick-release arms, 3.0m projection |

| DF-AW-450 |

Medium awning |

450 gsm PVC |

Family caravans; long-stay campsites |

Reinforced hems, zip-in annex ready |

| DF-AW-600 |

Annex system |

600 gsm PVC or acrylic |

Rental fleets; permanent setups |

Full annex, privacy panels, optional motorised roller |

| DF-AW-UL |

Ultralight |

Ripstop polyester |

Campervan & backpacking |

Lightweight, compact pack, breathable |

| DF-AW-PRINT |

Branded valance |

300–450 gsm PVC |

Rental fleets, commercial branding |

UV-stable digital print, colorfast inks |

Customization & Branding

Fleet operators and OEM partners frequently request customized awnings. Our customization services include:

- Size and projection adjustments to match awning rails.

- Custom printed valances and sidewalls with fade-resistant inks.

- Logo placement, safety markings, and QR-coded maintenance labels.

- Hardware options tuned for coastal environments (e.g., stainless fittings).

- Integration with aftermarket frame kits and annex connectors.

Installation Guide & Best Practices

Correct installation dramatically prolongs the service life of an awning and improves safety. Below we provide essential steps common to most installations; always consult model-specific instructions included with each product.

Site & Vehicle Preparation

- Park on level ground with adequate clearance from trees, powerlines and structures.

- Inspect the awning rail and vehicle integrity for corrosion or deformation before mounting.

- Remove sharp stones and objects around the deployment area.

Mounting & Tensioning

- Fit the awning into the caravan rail following the manufacturer’s rail insertion technique — take care to avoid twisting the fabric.

- Extend the awning slowly, ensuring arms and support struts are fully engaged before tensioning.

- Use supplied tensioning straps or ratchets to eliminate sagging; sagging invites wind-lift and ponding.

Wind, Rain & Winter Care

For windy or stormy weather, retract or fully secure the awning. Prolonged exposure to heavy rain can cause ponding; always ensure proper slope and drainage. For winter storage, remove detachable annexes, dry the fabric thoroughly and store in a cool, dry place to prevent mildew.

Maintenance & Repairs

Routine maintenance extends awning life and reduces downtime. Recommended maintenance schedule:

- After each trip: brush off debris, rinse salt from coastal environments, and allow to dry before packing.

- Monthly: inspect seams, zips and fittings for wear; apply lubricant to moving parts where appropriate.

- Annually: perform a full inspection of fabric tensile condition and hardware—replace worn webbing or corroded fittings.

Common Repairs

Minor repairs such as small puncture patches, seam re-welding and zip replacement can be performed by trained service centres. Derflex offers repair kits for simple field repairs and can assist with local service partners for larger jobs.

Quality Control & Certifications

Derflex follows a controlled production and testing protocol: incoming raw material inspection, in-line process checks, and final product audits. Certifications and documentation available upon request include:

- ISO 9001 Quality Management Systems

- Material test reports for tensile strength, hydrostatic head and UV ageing

- REACH compliance guidance for chemical substances used in coatings

Warranty & Service Plans

Our standard warranty covers manufacturing defects in materials and workmanship under normal use. Warranty terms vary by model; extended warranties and service contracts for rental fleets are available. For exact terms, request a warranty schedule with your quote.

Ordering, Lead Times & Logistics

Derflex handles both small-sample orders and large OEM fleet deployments. Typical lead times:

- Sample & stock awnings: 1–3 weeks (subject to destination).

- Custom-printed or bespoke awnings: 4–10 weeks depending on complexity and quantity.

We ship worldwide via sea freight, airfreight and express couriers. Our logistics team assists with INCOTERMS, HS codes and export documentation to streamline customs clearance.

Case Studies — Real-World Deployments

Derflex awnings have been supplied to:

- A UK-based rental fleet for national holiday parks — customised printed valances and reinforced annex connections reduced downtime by 37% during peak season.

- A European motorhome brand for an OEM supply contract — integrated rail-compatible awnings delivered with documented wind-load performance testing.

- Adventure tour operators in Australasia — ultralight awnings tailored to roof-rack mounting and rapid-deploy use.

Comparing Derflex Awning Types — Quick Reference

| Feature |

Roll-out PVC |

Acrylic Canvas |

Ultralight Ripstop |

| Durability |

High |

Medium-High |

Medium |

| Weight |

Medium |

Heavy |

Low |

| Waterproof |

Excellent |

Good (water-repellent) |

Depends on laminate |

| Packability |

Low |

Low |

High |

| Cost |

Medium |

High |

Low-Medium |

Environmental Considerations

We work to improve the lifecycle impact of awning materials. PVC offers long life which reduces replacement frequency, but recycling can be challenging. Where appropriate, we offer PE or textile composite options with lower-impact additives and guidance on local recycling options. For rental fleets, a repair-first approach typically reduces waste significantly.

Frequently Asked Questions (FAQ)

Q: Can I fit the awning myself?

A: Many Derflex awnings are designed for DIY installation, particularly roll-out models with simple rail systems. Complex annexes or motorised systems are usually installed by trained technicians—ask your sales rep for a recommended installer list.

Q: What is the wind rating for your awnings?

A: Wind ratings depend on the model and how the awning is secured. Typical rated performance is to moderate campsite winds when properly tensioned and anchored. We provide wind-load guidance and can provide tested performance data for fleet purchases.

Q: How do I choose between PVC and acrylic?

A: Choose PVC for waterproofing, ease of cleaning and welded seams. Choose acrylic if breathability, aesthetics and reduced condensation are priorities—common in premium, sunny-climate installations.

Q: Can you print our company logo on the valance?

A: Yes. We use UV-stable inks suitable for outdoor exposure. Send vector artwork and we will supply a digital mock-up and color-proof prior to production.

Q: Do you supply spare parts and repair kits?

A: Yes — spare parts, zips, roller mechanisms and repair kits are available. For fleets we can maintain a spare-parts stock as part of a service-level agreement (SLA).

Compliance & Export Notes

For international customers, we provide HS codes and testing documentation to support customs clearance. Some textile finishes may be subject to specific import regulations — consult local authorities. We also provide material safety data sheets (MSDS) for coatings upon request.

Contact & Sales Support

Contact our caravan awning team to get a tailored quote or technical drawing:

Email:info@derflex.com

When requesting a quote, please include vehicle make/model, awning rail type (if known), desired projection and any printing or annex options.

Get a Sample

We provide small fabric samples and demo awnings for fleet evaluations. Sample charges may apply; shipping is typically charged at cost. Email info@derflex.com with the SKU and your address to request.

Concluding Notes

Derflex caravan awnings are engineered for touring freedom — balancing durability, weight and convenience. From the weekend camper to fleet-scale OEM deployments, our team supports specification, testing and logistics to get you the right solution. Contact us for CAD drawings, sample pieces, or to schedule a product demo.