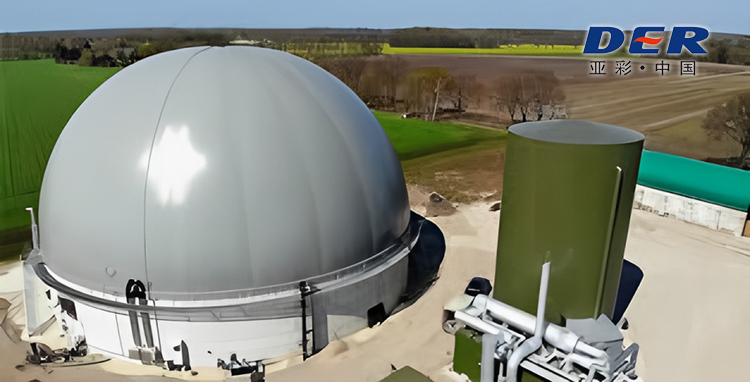

Flexible Biogas Container – Reliable Storage Solutions for Renewable Energy Systems

Flexible biogas containers are specially designed gas storage systems used to safely store biogas generated from anaerobic digestion processes. These containers play a critical role in modern renewable energy and waste-to-energy projects by providing a cost-effective, durable, and adaptable solution for biogas collection and storage.

As an experienced coated fabric manufacturer, DERFLEX supplies high-performance flexible biogas containers made from reinforced PVC coated fabrics. Our biogas storage solutions are widely used in agricultural biogas plants, wastewater treatment facilities, food waste recycling systems, and industrial anaerobic digestion projects worldwide.

What Is a Flexible Biogas Container?

A flexible biogas container, also known as a biogas storage bag or flexible gas holder, is a sealed membrane structure designed to store biogas under low pressure. Unlike rigid steel or concrete tanks, flexible containers are manufactured from technical fabrics that allow easy transportation, fast installation, and excellent adaptability to different site conditions.

These containers are typically installed above ground or partially buried and are connected directly to anaerobic digesters to collect biogas produced during the decomposition of organic materials.

Main Features

- Flexible, lightweight structure

- Gas-tight and odor-resistant design

- High resistance to chemicals and corrosion

- Easy installation and low maintenance

- Cost-effective compared to rigid tanks

DERFLEX Flexible Biogas Container Materials

PVC Coated Fabric for Biogas Storage

DERFLEX flexible biogas containers are manufactured using high-strength polyester base fabrics coated with specially formulated PVC compounds. These coatings provide excellent gas tightness, UV resistance, and long-term durability in harsh outdoor environments.

- High tensile strength polyester base fabric

- Multi-layer PVC coating for gas impermeability

- Anti-UV, anti-fungal, and anti-aging treatments

- Flame retardant options available

Gas Tightness & Chemical Resistance

Biogas typically contains methane, carbon dioxide, hydrogen sulfide, and moisture. DERFLEX biogas container fabrics are engineered to resist chemical attack from these components while maintaining long-term flexibility and sealing performance.

Technical Specifications of Flexible Biogas Containers

| Property | Typical Values |

|---|---|

| Material | PVC Coated Polyester Fabric |

| Fabric Weight | 900 – 1500 g/m² |

| Tensile Strength | 4000 – 9000 N / 5cm |

| Gas Tightness | Excellent (Low Gas Permeability) |

| Operating Temperature | -30°C to +70°C |

| Service Life | 10 – 15 Years |

Applications of Flexible Biogas Containers

DERFLEX flexible biogas containers are suitable for a wide range of renewable energy and environmental applications:

- Agricultural biogas plants

- Livestock manure digestion systems

- Food waste and organic waste treatment

- Municipal wastewater treatment facilities

- Industrial anaerobic digestion projects

- Temporary or mobile biogas storage systems

Thanks to their modular and flexible design, these containers can be adapted to different project scales, from small farm-based digesters to large industrial biogas installations.

Advantages of Flexible Biogas Containers Compared to Rigid Tanks

Lower Installation Cost

Flexible biogas containers require minimal foundation work and can be installed much faster than concrete or steel tanks, significantly reducing overall project costs.

Ease of Transportation

The containers can be folded and transported easily, making them ideal for remote locations or international projects.

Corrosion Resistance

Unlike metal tanks, flexible containers are resistant to corrosion caused by moisture and hydrogen sulfide in biogas.

Expandable and Replaceable

Flexible biogas storage systems can be expanded or replaced more easily as project requirements change.

Why Choose DERFLEX Flexible Biogas Containers?

Professional Manufacturing Experience

DERFLEX has extensive experience in coated fabric manufacturing for environmental and industrial applications, ensuring stable quality and reliable performance.

Customized Solutions

- Customized container sizes and shapes

- Single or double membrane designs

- Customized fabric thickness and strength

- Optional insulation and protective layers

Global Project Supply

DERFLEX flexible biogas containers have been supplied to projects across Europe, Asia, Africa, and the Americas, meeting international quality and safety standards.

Quality Control & Testing

All DERFLEX biogas container fabrics undergo strict quality testing, including tensile strength, tear resistance, coating adhesion, gas permeability, and accelerated aging tests. This ensures reliable performance throughout the product’s service life.

Frequently Asked Questions (FAQ)

What is the lifespan of a flexible biogas container?

Under normal operating conditions, DERFLEX flexible biogas containers typically have a service life of 10 to 15 years, depending on material selection and environmental exposure.

Is the biogas container completely gas-tight?

Yes. DERFLEX uses specially formulated PVC coatings to ensure excellent gas tightness and minimal methane leakage.

Can flexible biogas containers be customized?

Yes. DERFLEX offers customized flexible biogas containers tailored to project capacity, site conditions, and regulatory requirements.

Contact DERFLEX – Flexible Biogas Container Manufacturer

If you are looking for a reliable flexible biogas container manufacturer and supplier, contact DERFLEX for professional solutions and technical support.

Website: https://www.derflex.com