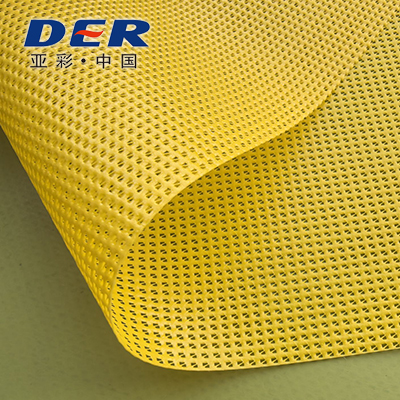

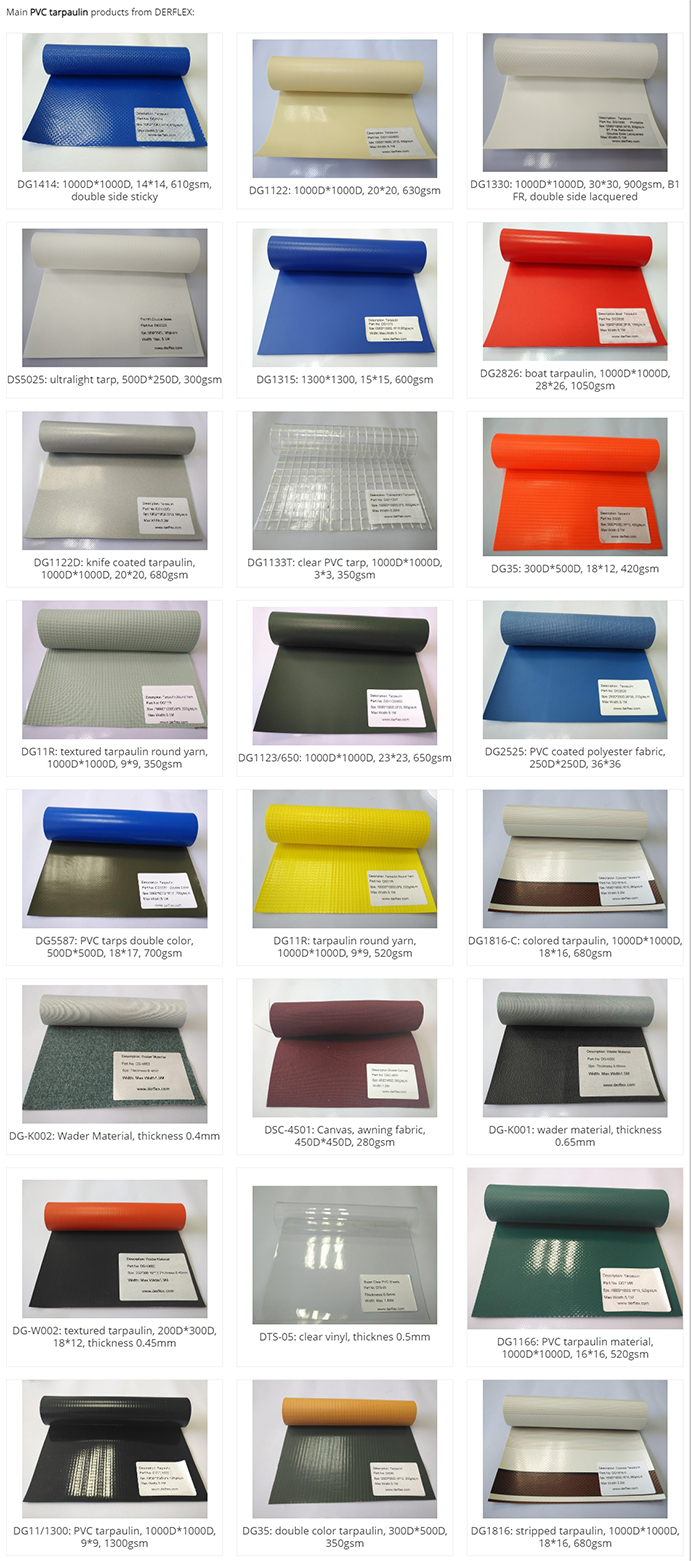

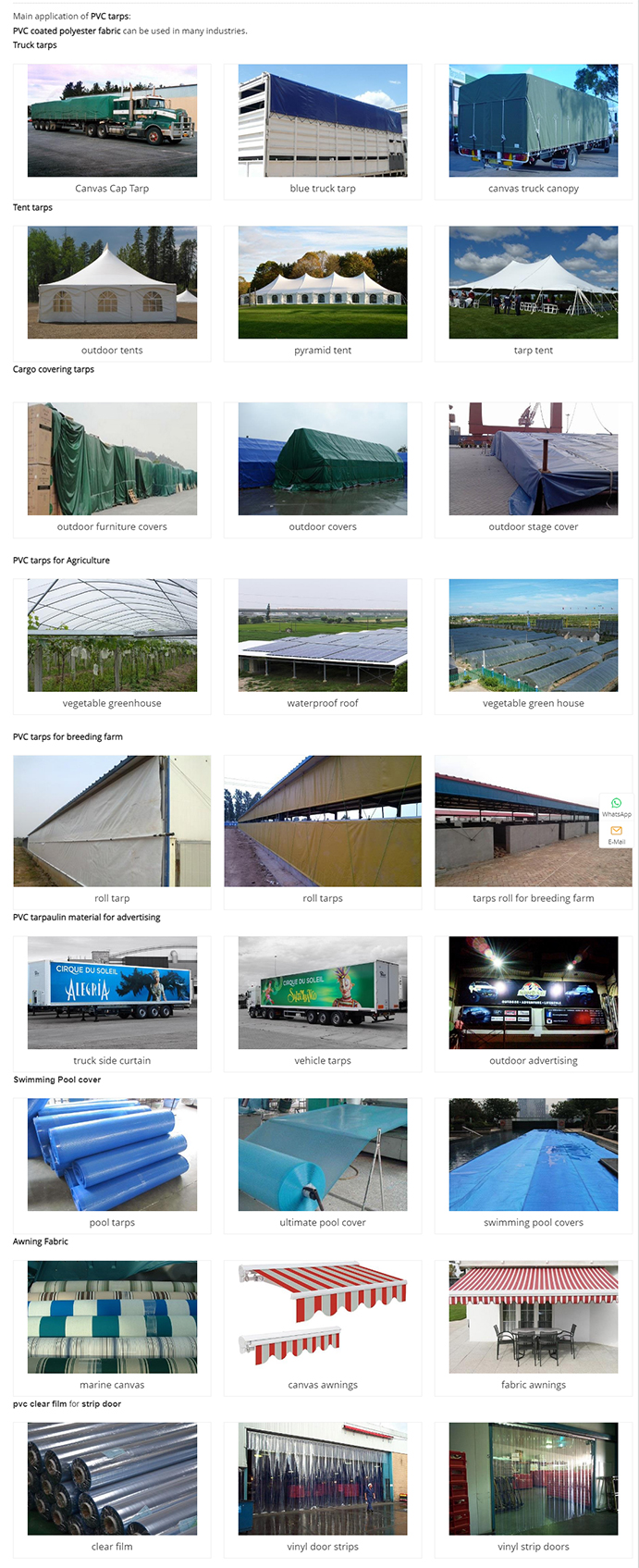

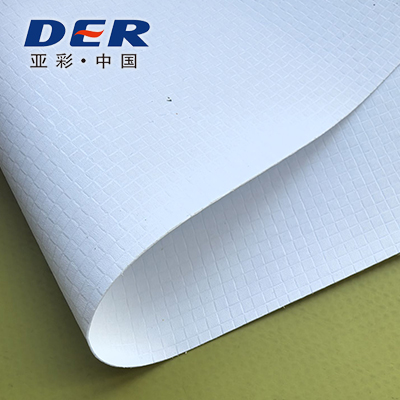

- tarp

- Frontlit banner

- PVC flex backlit

- Blockout banner

- PVC vinyl sticker

- Tarpaulin

- PVC mesh banner

- PVC preformated vinyl

- Reflective vinyl

- Dye Sublimation fabric

- PVC Stretch Ceiling Film

- Super clear pvc film

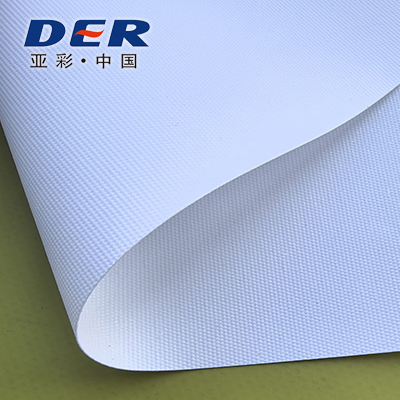

- PVC coated fabrics

- TPO coated fabric

- TPU coated fabric

- Inkjet media

- Textile banner

- Mesh banners

- New Products

- customized PVC tarps products

- PVC Foam Board Sheet

- Profile download

- Services Hotline

+86-021-54361792 / 54361798 - Email

sales@derflex.com

|

|

industrial fabrics Manufacturer

Derflex industrial fabrics manufacturer supplies high performance industrial fabrics, heavy duty technical textile solutions for industrial and engineering applications. Explore product specs, colours, certifications & global supply.

|

|

|||||||||||||||||||||||||||

Industrial Fabrics Manufacturer – High Performance Technical Fabrics by DerflexWelcome to Shanghai DER New Materials Co., Ltd. (“Derflex”) – your trusted industrial fabrics manufacturer and supplier of advanced technical textile solutions. Whether you’re searching for “industrial fabrics heavy duty”, “industrial use technical fabric for manufacturing”, or “industrial fabric supplier for engineering applications”, you’ve come to the right place. Product IntroductionOur industrial fabrics are engineered for demanding settings – designed for high-stress environments, continuous operation, mechanical abrasion, chemical exposure, temperature extremes and long service life. As a top industrial fabrics manufacturer, Derflex delivers solutions tailored for sectors such as conveyor systems, industrial curtains, heavy logistics, outdoor structures, insulation covers, and more. These fabrics are not your standard “industrial textile” – they are high-performance, coated composites with enhanced durability, dimensional stability and engineered properties. Keywords like “industrial fabrics manufacturer China”, “heavy duty industrial fabric for conveyor belts”, “industrial PVC coated fabric for factory use” reflect what our global customers search for, and our page addresses those needs. Specifications / Technical Parameters

Product ColoursAvailable standard colours include Blue, Green, Grey, and Black. We also offer customised colour matching according to customer branding or visual design requirements. For “industrial colour coated fabric for heavy duty use” or “custom colour industrial technical textile”, Derflex provides flexibility. Product FeaturesProduct ApplicationOur industrial fabrics serve a wide array of industrial and engineering applications. Typical usage includes: Shanghai DER New Materials Company ProfileFounded and headquartered in Shanghai, Derflex (Shanghai DER New Materials Co., Ltd.) is a premier industrial fabrics manufacturer and exporter dedicated to advanced technical textiles. With decades of experience, we serve global industries with customised fabric solutions, supported by robust R&D, strict quality control, international certifications and global logistics. We are committed to innovation, reliability and customer-centric service — making us your partner of choice when you search for “industrial fabric manufacturer China” or “industrial textile supplier global”. Certificates of Derflex New MaterialOur fabrics comply with multiple international standards and certifications, covering mechanical strength, temperature resistance, flame retardancy, chemical resistance and environmental compliance. Available certifications include ISO 9001 quality management, REACH compliance, UL flame-resistant approval, EN ISO mechanical standards, and customer-specific audit reports. Why Choose UsWhen selecting an industrial fabric provider, you want more than just a generic textile. Here’s why Derflex stands out: Installation PrecautionsTo ensure optimal performance of your industrial fabric, follow these installation guidelines: Sold to CountriesDerflex’s industrial fabrics have been exported and installed in diverse regions worldwide, including the United States, Canada, Germany, UK, France, Italy, Spain, Brazil, Mexico, Australia, UAE, Saudi Arabia, South Africa, India, Thailand, Vietnam and more. If you are searching for a global supplier of “industrial fabric supplier international shipping”, we deliver strategically. Use & FAQsQ: What is the minimum order quantity (MOQ) for your industrial fabrics?A: Our standard MOQ starts from 1,000 m² for standard widths and colours. For custom widths or coatings, MOQ may vary – please contact our sales team. Q: Can you provide customised colours, widths and weights?A: Yes. We support custom widths from 0.5 m up to 3.2 m (and wider on request), weights from ~300 g/m² up to 1500 g/m², and bespoke colours per RAL or client sample. This addresses search queries like “custom industrial fabric width heavy duty”. Q: Do you provide samples before mass production?A: Certainly. We can deliver small sample swatches or roll samples for your testing of properties such as tensile, elongation, coating adhesion, and colour match – great for “industrial fabric sample testing” requirements. Q: What lead time can I expect for delivery?A: Typical lead time for standard products is 4-6 weeks after order and payment confirmation. Custom specifications may require 6-10 weeks. For urgent orders, please contact us with your timeline. Q: How should I maintain and clean the fabric?A: Cleaning depends on coating type: for PVC/PU coated fabrics, wipe with mild soap and water; avoid strong solvents unless specified. Avoid drag across sharp surfaces and inspect regularly for wear – this aligns with “industrial fabric maintenance guidance”. Q: Do you ship worldwide and handle import/export logistics?A: Yes. We support global export, including FOB, CIF, DAP terms. We work with international freight forwarders and can assist with customs documentation for “industrial fabric export solutions”. Relevant KeywordsIndustrial fabrics manufacturer, heavy duty industrial fabric, industrial technical textile supplier, industrial coated fabric for manufacturing, industrial fabric for conveyor belts, industrial fabric high temperature, industrial fabric fire retardant, custom industrial fabric colours, industrial fabric exporter, industrial fabric sample testing, technical textile for industrial use. We trust that this product page gives you a comprehensive overview of our industrial fabric offerings and aligns with what you’re searching for when you type queries like “industrial fabrics manufacturer China”, “industrial fabric heavy duty technical textile”, or “industrial fabric supplier for global export”. For further details, custom requests, or sample orders, please contact us via our website. |

|||||||||||||||||||||||||||