- tarp

- Frontlit banner

- PVC flex backlit

- Blockout banner

- PVC vinyl sticker

- Tarpaulin

- PVC mesh banner

- PVC preformated vinyl

- Reflective vinyl

- Dye Sublimation fabric

- PVC Stretch Ceiling Film

- Super clear pvc film

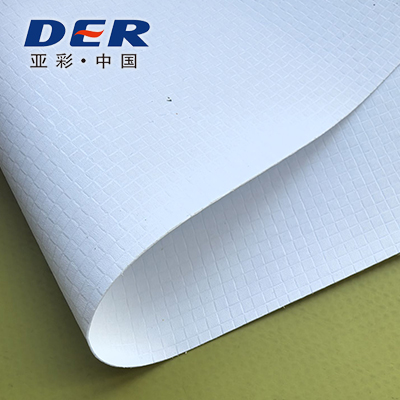

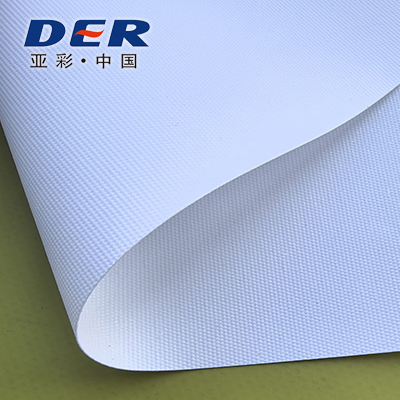

- PVC coated fabrics

- TPO coated fabric

- TPU coated fabric

- Automotive Protection Film

- Inkjet media

- Textile banner

- Mesh banners

- New Products

- customized PVC tarps products

- PVC Foam Board Sheet

- Profile download

- Services Hotline

+86-021-54361792 / 54361798 - Email

sales@derflex.com

|

|

Machine Tool Protective Cover

DERFLEX machine tool protective covers – tailored heavy-duty protective fabrics for CNC machines, lathes, milling machines and industrial equipment. Dustproof, oil-resistant, flame-retardant options. Custom sizes, colors and mounting accessories available.

|

|

||||||||||||||||||||||||||||||||

Machine Tool Protective Cover — Heavy Duty CNC & Lathe Covers by DERFLEXDurable fabric covers engineered to protect machine tools from dust, metal chips, coolant splashes, oil contamination and abrasion. Customizable materials and mounting options for industrial environments. Product OverviewDERFLEX Machine Tool Protective Covers are engineered protective textile solutions designed to extend the service life and reduce maintenance downtime of CNC machines, lathes, milling machines, EDMs, grinders and other precision equipment. Manufactured from high-performance coated fabrics — including PVC coated polyester, PU coated polyester and TPU laminated materials — these covers combine mechanical durability, oil and coolant resistance, and easy-to-clean surfaces. What makes DERFLEX machine covers different?Unlike simple dust sheets, DERFLEX covers are purpose-built for industrial conditions. Features include reinforced hems, abrasion-resistant panels in high-wear zones, integrated inspection windows, service flaps for maintenance access, and engineered fastener systems (Velcro, zippers, snap buttons or metal D-rings) to ensure a snug, safe fit. Our manufacturing and quality control processes ensure dimensional accuracy and consistent protective performance across production batches. Expertise, Authority & Trust (EEAT)Expertise: DERFLEX has over 15 years of experience developing coated technical textiles for industrial protection. Our R&D team includes textile engineers, polymer chemists and application specialists who optimize fabric constructions for specific machine protection challenges such as coolant compatibility, low-temperature flexibility and chip abrasion resistance. Authority: We supply machine covers and industrial fabrics to OEMs, machine shops and maintenance providers across Europe, North America and Asia. DERFLEX provides technical datasheets, recommended welding and sewing parameters, and third-party testing for abrasion, tensile strength and chemical resistance. Trust: All production batches undergo in-line inspection and final quality checks including coating adhesion, hydrostatic testing (where applicable) and seam strength verification. Customers receive batch traceability documentation and can request independent lab reports for compliance and procurement audits. Technical Specifications

Note: Exact technical values depend on chosen fabric and construction. DERFLEX provides full product datasheets and test reports upon request. Product Colors & FinishesOur standard color palette is designed for industrial environments and reflects the need to hide grime while maintaining a professional appearance. Standard finishes and colors include: Finishes: matte finish to reduce glare, anti-dirt coatings to facilitate cleaning, and antimicrobial finishes for sensitive environments. PANTONE matched colors available for OEM branding. ApplicationsDERFLEX machine tool protective covers are used wherever machinery needs protection from environmental or process-related hazards. Typical applications include: We also supply covers for outdoor machine housings where weatherproofing and UV resistance are required. DERFLEX engineers consult on material selection to ensure compatibility with machining fluids and ambient conditions. About DERFLEXShanghai DER New Materials Co., Ltd. (DERFLEX) specializes in advanced coated textile solutions for industrial, architectural and transportation markets. With decades of experience in coating technology, lamination and fabric engineering, DERFLEX provides high-quality materials and finished products designed to perform reliably under demanding conditions. Our integrated capabilities — from R&D and pilot trials to full-scale production and finishing — allow us to offer customized machine protection solutions. We partner with OEMs, maintenance service providers and industrial end-users to deliver tailored covers, rapid prototypes and long-term supply agreements. Certifications & TestingDERFLEX maintains a rigorous quality system and can provide certified test reports and compliance documentation as part of our supply process. Typical certifications and test capabilities include: For specialized environments, DERFLEX can coordinate third-party laboratory tests and provide certification packages required by procurement or regulatory bodies. Why Choose DERFLEX Machine Tool CoversTailored ProtectionWe design covers to match machine geometry and service routines — offering inspection windows, flaps, cable seals and fastener options so covers integrate seamlessly with maintenance workflows. Material ExpertiseOur knowledge of coating chemistry and textile structures ensures the right balance of flexibility, durability and chemical resistance for each application. Production ConsistencyVertically integrated manufacturing means consistent coating weight, adhesion and dimensional stability across large orders — critical for serialized OEM machines. Responsive SupportWe provide technical guidance on installation, maintenance and warranty procedures, and support prototype iterations for complex or irregular machine shapes. Installation & Maintenance PrecautionsExport Markets — Sold to CountriesDERFLEX supplies machine tool protective covers globally. Representative export destinations include: United States, Canada, Germany, United Kingdom, France, Italy, Spain, Netherlands, Sweden, Poland, Russia, Turkey, UAE, Saudi Arabia, Israel, India, South Korea, Japan, Australia, New Zealand, Brazil, Mexico, South Africa and more. We handle export documentation, packaging requirements and local compliance support to streamline procurement. Frequently Asked Questions (FAQs)Q1: Can you make covers for irregular-shaped machines?A: Yes. DERFLEX offers custom design services, including on-site measurement support or guidance from provided CAD drawings and photos. We produce prototypes for fit verification before mass production. Q2: Are the covers resistant to cutting fluids and coolants?A: Our standard fabric options have been formulated for compatibility with common cutting fluids and coolants. Please specify the exact fluids used so we can confirm compatibility or recommend a suitable coating. Q3: Do you provide flame-retardant covers?A: Flame-retardant (FR) options are available. FR performance and certification depend on the selected material and testing standard (EN, ASTM, NFPA, etc.). Contact us to specify required standards so we can produce compliant samples. Q4: How do I order replacement panels or spare fasteners?A: DERFLEX maintains spare parts and can supply replacement panels, zippers, Velcro strips and other hardware. Provide your order number or model details to request spares. Q5: What is lead time for custom covers?A: Typical lead times are 10–21 days for prototype/sample units and 25–45 days for bulk production depending on complexity and current production schedule. Expedited services available for urgent needs. Q6: Do you offer OEM branded covers?A: Yes. We support OEM branding with custom colors, printed logos and packaging tailored to your brand requirements. Get a Quote or Request a SampleTo request a quote, technical datasheet or sample for machine tool protective covers, please contact DERFLEX sales at sales@derflex.com or visit our contact page to submit drawings and application details. Provide machine dimensions, expected exposure (indoor/outdoor), typical coolant or lubricants used, and any required certifications so we can recommend the ideal material and construction. Request Quote / Request Samples |

||||||||||||||||||||||||||||||||