PVC Fabric Materials – Industrial-Grade PVC Coated Fabrics Manufacturer

As a global leader in coated textile solutions specializes in the research, development, and manufacturing of high-performance PVC fabric materials for demanding industrial, agricultural, architectural, and commercial applications. Our PVC fabrics are engineered to deliver exceptional durability, weather resistance, safety compliance, and long-term value across diverse environments.

PVC fabric materials also known as PVC coated fabrics or PVC laminated fabrics—combine high-strength base textiles with advanced polyvinyl chloride coatings. This structure enables superior waterproofing, flame retardancy, UV resistance, chemical stability, and mechanical strength, making them a preferred material for tarpaulins, covers, membranes, tents, inflatable structures, banners, and protective systems worldwide.

Why Choose DERFLEX PVC Fabric Materials

- More than 15 years of professional PVC coated fabric manufacturing experience

- Strict quality control compliant with EU & US standards

- Customizable coatings, weights, colors, and functional additives

- OEM & ODM solutions for global brands and distributors

- Proven performance in extreme climates and industrial conditions

What Are PVC Fabric Materials?

PVC fabric materials are composite textiles produced by coating or laminating a flexible PVC layer onto woven or knitted base fabrics such as polyester or nylon. The base fabric provides tensile strength and tear resistance, while the PVC coating adds waterproofing, abrasion resistance, flame retardancy, and environmental protection.

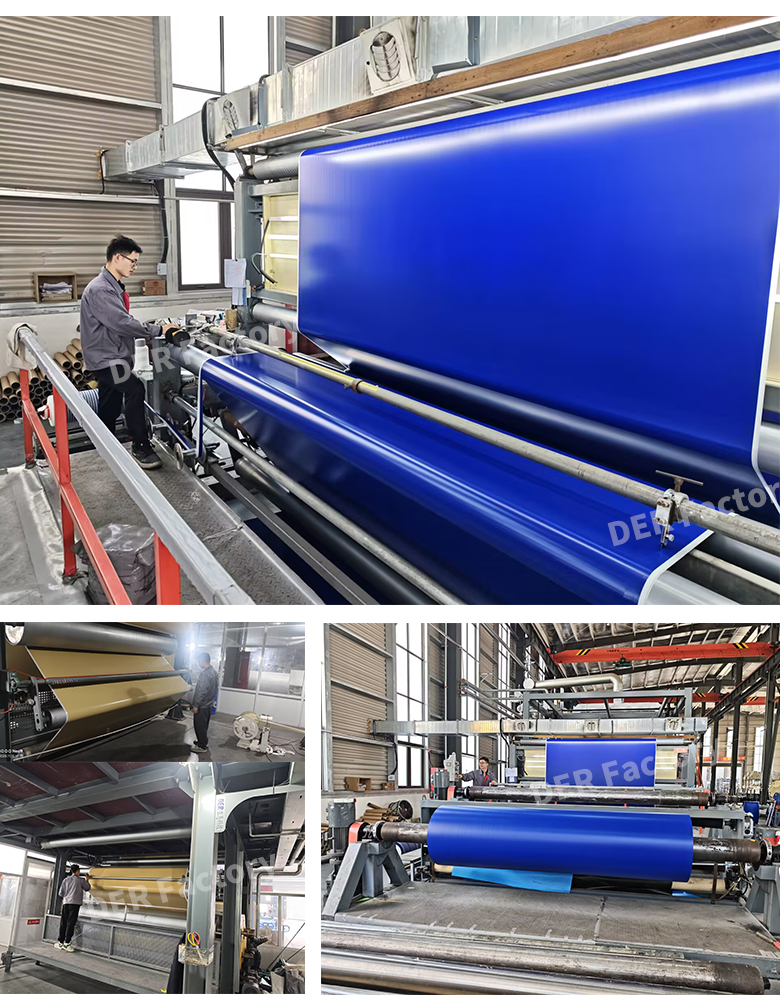

At DERFLEX, we manufacture PVC fabrics using advanced knife-over-roll coating, hot lamination, and calendering technologies to ensure uniform thickness, excellent adhesion, and long service life. Each production step is precisely controlled to meet application-specific requirements.

Core Features of PVC Fabric Materials

1. Outstanding Waterproof Performance

PVC fabric materials are inherently waterproof. The dense PVC coating forms an impermeable barrier that prevents water penetration even under prolonged exposure to rain, snow, or standing water. This makes them ideal for outdoor covers, tents, truck tarpaulins, and agricultural protection.

2. High Mechanical Strength

By selecting high-tenacity polyester base fabrics, DERFLEX PVC materials achieve excellent tensile strength, tear resistance, and dimensional stability. These properties are essential for large-span structures, heavy-duty tarps, and industrial containment systems.

3. Flame Retardant Options

Our PVC fabric materials can be manufactured to meet international flame retardant standards such as EN13501, DIN 4102-B1, NFPA 701, and CPAI-84. Flame retardant PVC fabrics are widely used in public venues, construction sites, and transportation applications.

4. UV & Weather Resistance

Special UV stabilizers and anti-aging additives protect PVC fabrics from degradation caused by sunlight exposure. This ensures color stability, flexibility retention, and mechanical performance over years of outdoor use.

5. Chemical & Corrosion Resistance

PVC fabric materials resist acids, alkalis, oils, and many industrial chemicals. This makes them suitable for waste containment, chemical covers, biogas membranes, and environmental protection projects.

Manufacturing Technologies at DERFLEX

DERFLEX operates modern production lines equipped with advanced coating and lamination systems. Our manufacturing processes include:

- Knife Coating – Precise PVC application for heavy-duty industrial fabrics

- Hot Lamination – Smooth surface finish and excellent flexibility

- Calendering – High-gloss, uniform PVC films and membranes

- Surface Treatments – Acrylic, PVDF, and anti-fungal coatings

Each PVC fabric roll undergoes strict inspection for thickness, weight, adhesion, tensile strength, and color consistency before shipment.

PVC Fabric Material Specifications

| Parameter | Range |

|---|---|

| Base Fabric | Polyester 250D – 1300D |

| Weight | 240 – 1500 g/m² |

| Thickness | 0.25 – 1.5 mm |

| Width | Up to 5.1 meters |

| Surface Finish | Matte, Glossy, Semi-gloss |

| Functional Options | FR, UV, Anti-fungal, Anti-static |

Main Applications of PVC Fabric Materials

Industrial Tarpaulins & Covers

PVC fabrics are widely used for truck tarpaulins, machinery covers, warehouse curtains, and industrial enclosures due to their durability and weather resistance.

Agricultural & Farming Use

In agriculture, PVC fabric materials protect crops, livestock, silage, and equipment from harsh environmental conditions. They are also used in greenhouse covers and biogas digester membranes.

Architectural & Structural Membranes

High-strength PVC fabrics are used in tensile membrane structures, awnings, canopies, and roofing systems, combining aesthetics with structural performance.

Advertising & Printing

Printable PVC fabrics provide excellent ink adhesion and dimensional stability for banners, billboards, backdrops, and exhibition graphics.

Inflatable & Leisure Products

Air-tight PVC coated fabrics are essential for inflatable boats, bounce houses, water parks, and emergency rescue equipment.

Quality Assurance & Certifications

DERFLEX implements a comprehensive quality management system from raw material sourcing to finished product delivery. Our PVC fabric materials comply with:

- REACH & RoHS environmental regulations

- ISO 9001 quality management standards

- International flame retardant certifications

- Third-party SGS and TÜV testing

Customization & OEM Services

Understanding that different industries require different performance characteristics, DERFLEX offers full customization of PVC fabric materials, including:

- Custom weights, colors, and embossing patterns

- Special coatings for anti-slip, self-cleaning, or anti-static performance

- Brand-specific packaging and labeling

- Technical support from design to application

Global Supply & Logistics

DERFLEX supplies PVC fabric materials to customers across North America, Europe, South America, the Middle East, and Asia. With efficient production planning and stable logistics partnerships, we ensure on-time delivery and consistent quality for every order.

Frequently Asked Questions (FAQ)

How long do PVC fabric materials last outdoors?

With proper UV stabilization and surface treatment, DERFLEX PVC fabrics can last 5–10 years or longer depending on climate and application.

Are your PVC fabrics environmentally compliant?

Yes. Our products meet REACH and RoHS requirements, and we continuously optimize formulations for lower environmental impact.

Can you produce flame retardant PVC fabrics?

Absolutely. We offer multiple flame retardant grades compliant with international standards for public and industrial use.

Contact DERFLEX – Your Trusted PVC Fabric Materials Supplier

If you are looking for a reliable manufacturer of high-quality PVC fabric materials, DERFLEX is your ideal partner. Contact our technical sales team today to discuss your project requirements and receive professional recommendations.

Official Website: https://www.derflex.com