PVC Film Manufacturer

DERFLEX is a professional PVC film manufacturer delivering high-performance PVC film solutions for global industrial markets. With advanced extrusion and calendering technology, strict quality management, and application-driven formulation expertise, DERFLEX supplies PVC films trusted across advertising, construction, packaging, medical, and industrial protection sectors.

Factory Direct Flexible & Rigid PVC OEM / ODM Global ExportDERFLEX – Professional PVC Film Manufacturing Expertise

DERFLEX is not a trading intermediary but a direct manufacturer specializing in PVC film production. We control every stage of the process—from raw PVC resin selection and compounding to extrusion, calendering, surface treatment, and inspection—ensuring stable quality and reliable long-term supply.

Our PVC film solutions are engineered to meet demanding industrial requirements while maintaining cost efficiency and consistency for large-scale applications.

What Is PVC Film?

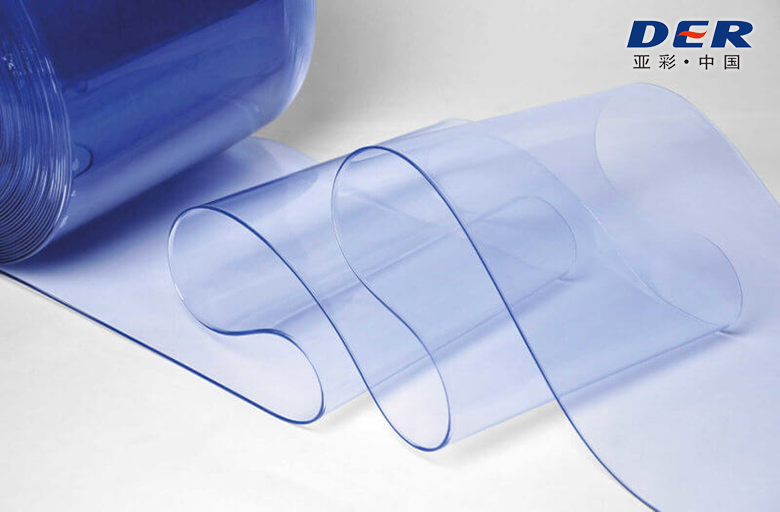

PVC film is a thermoplastic material produced by processing polyvinyl chloride resin with plasticizers, stabilizers, and functional additives. Depending on formulation and production method, PVC films can be flexible or rigid, transparent or opaque, smooth or textured.

Due to its versatility, durability, and chemical resistance, PVC film is widely used in industrial, commercial, and consumer applications.

PVC Film Manufacturing Technologies

DERFLEX employs advanced manufacturing technologies to produce high-quality PVC films:

- Calendered PVC Film: Excellent thickness uniformity and surface smoothness

- Extruded PVC Film: Cost-effective production for wide industrial usage

- Laminated PVC Film: Enhanced strength through multi-layer structures

Each technology is selected based on application requirements and performance expectations.

Flexible PVC Film vs Rigid PVC Film

DERFLEX produces both flexible and rigid PVC films, each tailored to specific applications:

- Flexible PVC Film: Soft, bendable, suitable for curtains, covers, packaging, and protective uses

- Rigid PVC Film: High stiffness and dimensional stability for printing, thermoforming, and structural applications

Key Performance Advantages of DERFLEX PVC Film

- Excellent transparency or controlled opacity

- High tensile strength and tear resistance

- Good chemical and oil resistance

- Weatherability and UV resistance options

- Flame retardant formulations available

- Stable thickness and smooth surface quality

Technical Specifications Overview

| Parameter | Typical Range |

|---|---|

| Material | PVC resin with functional additives |

| Thickness | 0.05 – 1.5 mm |

| Width | Up to 2200 mm |

| Surface Finish | Glossy / Matte / Embossed |

| Transparency | Clear / Translucent / Opaque |

| Special Properties | UV, FR, Anti-static, Anti-mildew |

Main Applications of PVC Film

DERFLEX PVC films are widely applied across industries:

- Advertising graphics and printing films

- Construction protection and decorative films

- Packaging and blister packaging materials

- Medical and hygienic products

- Industrial curtains and protective barriers

- Stationery and consumer products

Functional PVC Film Customization

DERFLEX offers a wide range of functional customization options, including:

- Flame retardant PVC film

- UV-resistant outdoor PVC film

- Cold-resistant PVC film

- Anti-static and conductive PVC film

- Colored, printed, or embossed PVC film

OEM & Private Label PVC Film Manufacturing

DERFLEX supports OEM and private label manufacturing for PVC film customers worldwide. From formulation tuning to packaging customization, our team ensures seamless integration into your supply chain.

Quality Control & Compliance

Quality assurance is a cornerstone of DERFLEX manufacturing operations. Our PVC films undergo strict inspection for thickness uniformity, mechanical performance, and surface quality.

We support compliance with international standards and customer-specific requirements.

Global Export & Supply Capability

DERFLEX PVC films are exported to Europe, North America, South America, the Middle East, and Asia-Pacific. Our global logistics experience ensures timely delivery and consistent product quality.

Why Choose DERFLEX as Your PVC Film Manufacturer?

- Direct manufacturer with full process control

- Advanced production technology

- Stable quality for large-volume orders

- Flexible customization and OEM services

- Competitive pricing and professional support

Contact DERFLEX – Your PVC Film Manufacturing Partner

If you are searching for a reliable PVC film manufacturer, DERFLEX provides the technical expertise, production capacity, and global supply reliability required for long-term cooperation.

Company: DERFLEX

Website: https://www.derflex.com

PVC Film Material Engineering & Formulation Expertise

As a professional PVC film manufacturer, DERFLEX places material engineering at the core of product development. PVC film performance is determined not only by resin quality, but also by precise formulation design. Our engineers optimize plasticizers, stabilizers, fillers, and functional additives to balance flexibility, strength, durability, and safety.

Different application scenarios—such as outdoor exposure, medical use, industrial protection, or advertising graphics—require different formulation logic. DERFLEX develops application-specific PVC film systems rather than one-size-fits-all products.

PVC Film Production Workflow & Process Control

DERFLEX operates industrial-scale PVC film production lines with strict process control. From compounding to final inspection, each stage is designed to ensure consistent performance across large production volumes.

- Raw PVC resin qualification and batch traceability

- Precision compounding with controlled dispersion

- Calendering or extrusion with thickness tolerance control

- Online surface inspection and defect elimination

- Post-production conditioning and aging stabilization

This disciplined workflow supports long-term supply stability for global customers.

PVC Film vs Other Plastic Films (PET / PE / PU)

Compared with PET, PE, and PU films, PVC film offers a unique balance of cost efficiency, versatility, and performance. While PET provides high stiffness and PE offers low cost, PVC stands out for its formulation flexibility.

- PVC vs PET: PVC offers better flexibility and weldability

- PVC vs PE: PVC provides superior strength and surface quality

- PVC vs PU: PVC is more cost-effective for large-volume applications

Industry-Specific PVC Film Solutions

DERFLEX supplies PVC film solutions tailored for specific industries:

- Advertising: Printable PVC films with smooth, ink-receptive surfaces

- Construction: Protective and decorative PVC films with weather resistance

- Medical: Transparent, compliant PVC films for hygiene applications

- Industrial: Heavy-duty PVC films for curtains, partitions, and protection

International Standards & Regulatory Compliance

DERFLEX PVC films can be manufactured to comply with major international regulations and standards, including REACH, ROHS, EN, and customer-specific specifications. Compliance is integrated into formulation design and production control.

Frequently Asked Questions (FAQ)

What thickness of PVC film should I choose?

Thickness depends on application requirements such as strength, flexibility, and durability. DERFLEX provides technical guidance based on end use.

Can PVC film be customized?

Yes. DERFLEX offers full customization including thickness, color, transparency, surface texture, and functional additives.

Is PVC film suitable for outdoor use?

With UV-resistant formulations, PVC film can perform reliably in outdoor environments.