PVC Lightweight Foam Core – Advanced Structural Core Material

PVC lightweight foam core is a high-performance structural material widely used in composite sandwich panels, industrial boards, signage, transportation, marine, construction, and renewable energy applications. Designed to deliver an exceptional balance between low weight, high strength, durability, and thermal insulation, PVC foam core has become a preferred solution for manufacturers seeking efficiency, reliability, and long-term cost savings.

At DERFLEX, we manufacture premium-grade PVC lightweight foam core materials using advanced foaming and extrusion technologies. Our products are engineered to meet the demanding requirements of global industrial markets while maintaining consistent quality, excellent machinability, and outstanding environmental resistance.

1. What Is PVC Lightweight Foam Core?

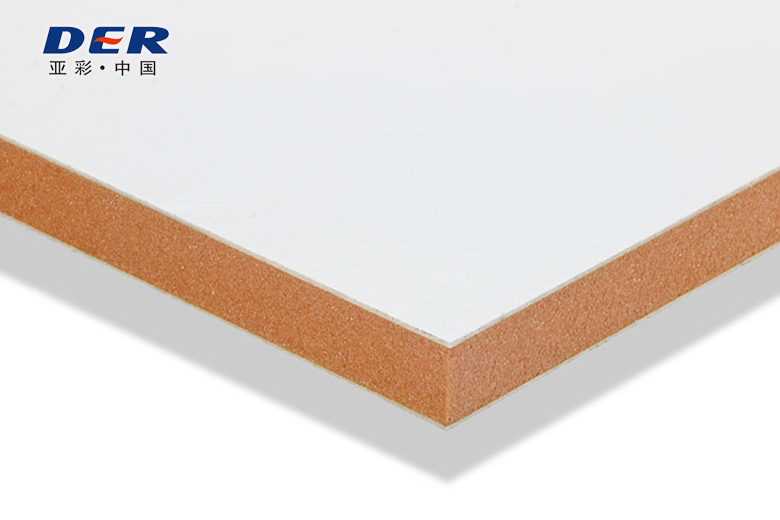

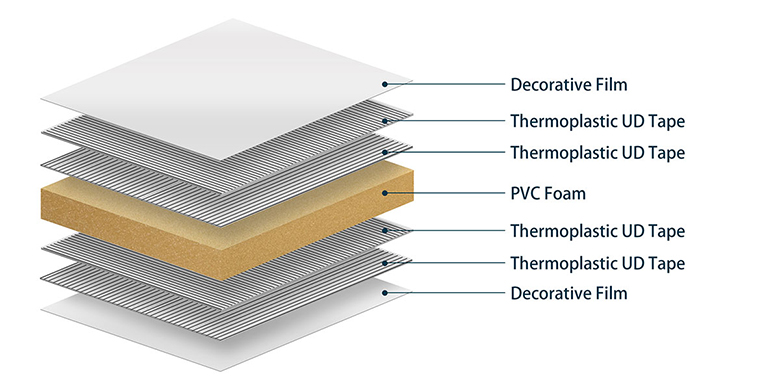

PVC lightweight foam core is a closed-cell or semi-closed-cell polymer foam material based on polyvinyl chloride (PVC). Through precise foaming control, microscopic air cells are uniformly distributed within the PVC matrix, dramatically reducing density while retaining structural integrity.

This unique internal structure allows the foam core to act as a load-bearing yet lightweight core layer when laminated between surface skins such as fiberglass, aluminum, steel, plywood, or PVC sheets.

Key Structural Characteristics

- Uniform cell structure for consistent mechanical performance

- Excellent compression and shear strength

- Low density with high stiffness-to-weight ratio

- Superior dimensional stability

- Resistance to moisture and chemicals

2. Why PVC Foam Core Is a Lightweight Advantage

Weight reduction is critical across modern industries. PVC lightweight foam core significantly reduces overall product weight without compromising performance, enabling easier handling, lower transportation costs, and improved energy efficiency.

Strength-to-Weight Optimization

Compared to solid PVC or traditional wood-based cores, PVC foam core delivers:

- Up to 60% weight reduction

- Higher bending stiffness in sandwich constructions

- Improved fatigue resistance

- Enhanced vibration damping

This makes it especially suitable for large-format panels, mobile structures, and applications where weight directly impacts operating costs.

3. Core Performance Properties

3.1 Mechanical Strength

DERFLEX PVC foam core exhibits excellent compressive strength, shear resistance, and impact tolerance. These properties ensure long-term reliability even under repeated loads.

3.2 Thermal and Acoustic Insulation

The closed-cell structure provides effective thermal insulation, reducing heat transfer in building panels and refrigerated structures. Additionally, PVC foam core helps dampen sound and vibration.

3.3 Water and Moisture Resistance

Unlike wood or paper-based cores, PVC foam core does not absorb water, swell, or rot. This makes it ideal for humid, marine, or outdoor environments.

3.4 Fire Performance

Flame-retardant formulations are available, meeting international fire safety standards for construction and transportation applications.

4. Manufacturing Technology at DERFLEX

DERFLEX utilizes advanced extrusion and foaming technology to ensure precise density control and consistent quality across every batch of PVC lightweight foam core.

Production Advantages

- Stable cell size and density distribution

- Smooth, uniform surface finish

- Custom thickness and density options

- High bonding compatibility with surface skins

Every production stage undergoes strict quality control, including density testing, compression testing, and dimensional accuracy inspection.

5. Applications of PVC Lightweight Foam Core

5.1 Composite Sandwich Panels

PVC foam core is widely used in sandwich panels for walls, floors, roofs, and partitions, delivering high rigidity with minimal weight.

5.2 Signage and Display Systems

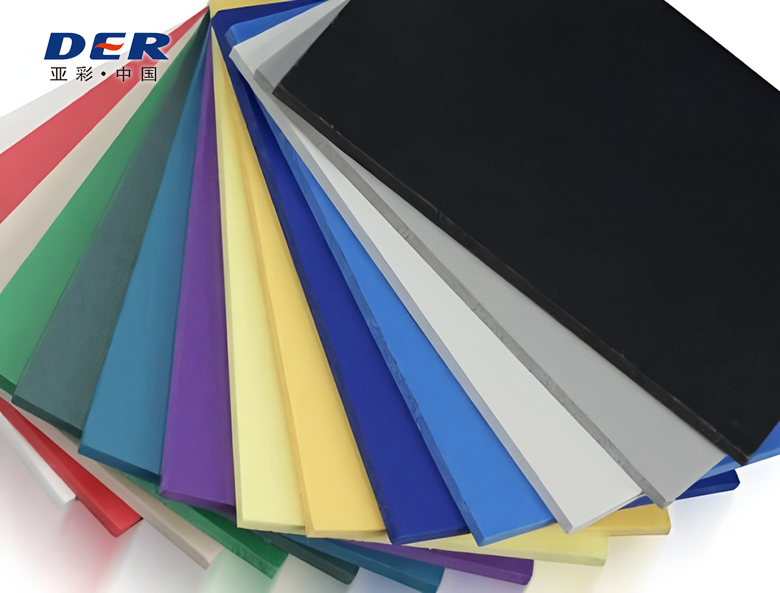

Its smooth surface, light weight, and easy machinability make PVC foam core ideal for advertising boards, exhibition panels, and digital printing substrates.

5.3 Construction and Building Materials

- Interior wall panels

- Ceiling systems

- Prefabricated modular buildings

- Insulated doors and partitions

5.4 Marine and Offshore Structures

PVC foam core is commonly used in boat decks, bulkheads, and marine panels due to its resistance to water, salt, and corrosion.

5.5 Transportation and Mobility

- RV and caravan panels

- Truck and trailer bodies

- Railway interior panels

- Aerospace auxiliary structures

6. Comparison with Other Core Materials

| Core Material | Weight | Moisture Resistance | Durability | Cost Efficiency |

|---|---|---|---|---|

| PVC Foam Core | Very Low | Excellent | High | High |

| Plywood | High | Poor | Medium | Medium |

| Honeycomb Core | Low | Medium | Medium | Low |

| Solid PVC | Very High | Excellent | High | Low |

7. Customization Options from DERFLEX

DERFLEX provides fully customized PVC lightweight foam core solutions to match specific project requirements.

- Density range customization

- Thickness and panel size options

- Flame-retardant grades

- UV-resistant formulations

- Special surface treatments

OEM and bulk orders are supported with stable lead times and consistent quality assurance.

8. Environmental and Sustainability Benefits

PVC lightweight foam core contributes to sustainability by reducing material usage and energy consumption throughout a product’s lifecycle.

- Lower transportation emissions due to reduced weight

- Long service life minimizes replacement frequency

- Recyclable PVC material options available

- Reduced waste compared to wood-based cores

DERFLEX continuously invests in environmentally responsible production processes to support global sustainability goals.

9. Why Choose DERFLEX PVC Lightweight Foam Core

- Professional PVC material manufacturer with decades of experience

- Advanced production technology and strict QC systems

- Global export capability and stable supply

- Technical support for application development

- Long-term partnership focus

Visit our official website for more details: https://www.derflex.com

10. Conclusion

PVC lightweight foam core is an advanced structural material that delivers outstanding performance across multiple industries. Its combination of low weight, high strength, moisture resistance, and design flexibility makes it an ideal solution for modern composite structures.

By choosing DERFLEX PVC lightweight foam core, manufacturers gain a reliable, cost-efficient, and future-ready core material engineered for long-term success.

Frequently Asked Questions

Is PVC foam core suitable for outdoor use?

Yes. DERFLEX PVC foam core is resistant to moisture, UV exposure, and environmental degradation, making it suitable for outdoor applications.

Can PVC foam core be laminated with different surface materials?

Absolutely. PVC foam core bonds well with fiberglass, aluminum, steel, and PVC skins.

Is flame-retardant PVC foam core available?

Yes. DERFLEX offers flame-retardant grades that meet international safety standards upon request.