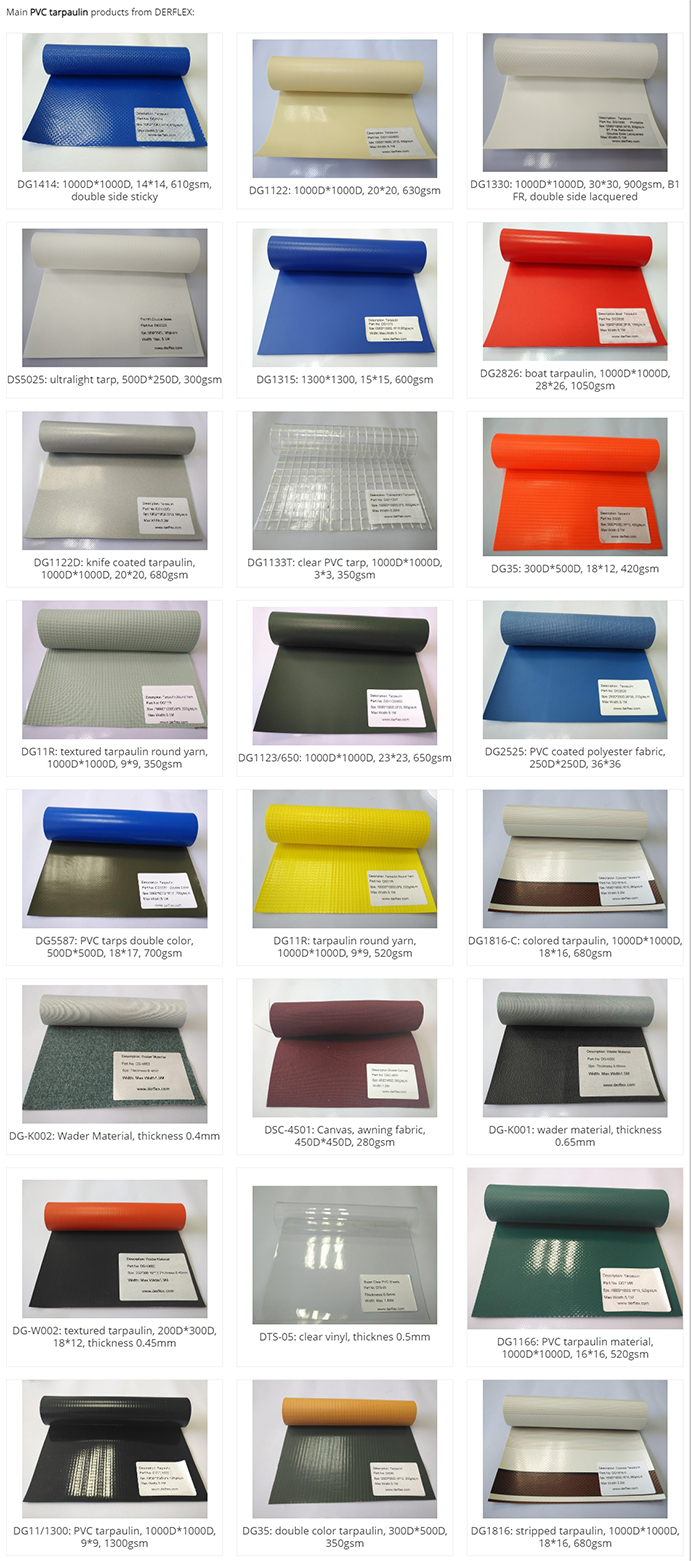

PVC Tarpaulin USA — Heavy-Duty PVC Tarpaulin & PVC Coated Fabrics

Durable waterproof PVC tarpaulin for truck covers, billboards, industrial enclosures and outdoor protection — manufactured to DERFLEX quality standards for markets in the United States and North America.

Product Introduction

DERFLEX PVC Tarpaulin USA series is a family of heavy-duty, PVC-coated polyester fabrics engineered for long-term outdoor use in harsh climates. Combining high-tenacity polyester base cloth with a formulated PVC coating, our tarpaulin material delivers exceptional tensile strength, waterproof performance, UV resistance and flame retardancy where required. Manufactured on modern coating lines with strict quality control, DERFLEX tarpaulins are widely used across logistics, advertising, agriculture, construction and event markets in the United States.

This page provides a complete overview for buyers and specifiers: product specifications, available colors, typical applications, technical features, installation precautions, certifications and FAQ. The content is optimized to help customers search from multiple angles — whether they are looking for "PVC truck tarpaulin", "banner PVC fabric USA", or "waterproof tarpaulin for outdoor use".

DERFLEX — Trusted Manufacturer & Expert Guidance

DERFLEX is an established manufacturer of PVC coated fabrics with decades of experience supplying export markets. We maintain ISO-certified production, independent lab testing and dedicated technical support for North American projects. Our R&D engineers work with suppliers and end-users to ensure material formulations meet performance expectations and regulatory requirements across jurisdictions.

Product Features

Waterproof & Weatherproof

Continuous PVC coating and heat-sealed seams create a fully waterproof membrane that resists rain, snow and high humidity.

High Tear & Tensile Strength

Multiple polyester weave counts and hot-melt bonding produce excellent tensile and tear resistance for truck covers and heavy-duty shelters.

UV Stabilized

UV stabilizers in both base yarn and coating minimize color fade and polymer degradation under prolonged sunlight exposure.

Flame Retardant Options

Available B1 / M2 / NFPA-701 compliant grades for public event, marquee and building wrap applications.

Printable Surface

High-resolution digital printing compatible top coats for billboard, banner and truck advertising panels.

Low-Temperature Flexibility

Formulations retain flexibility in cold climates—critical for winter operation and handling.

Product Specifications

Typical technical ranges — custom formulations and exact test data available on request.

| Property | Typical Value / Range |

|---|---|

| Base Fabric | Polyester 600D / 800D / 1000D / 1680D (plain / basket / cordura weave) |

| Coating | PVC on both sides (single/double coated) — high solids PVC plastisol or PVC-PU blend |

| Total Weight | 400 g/m² — 1200 g/m² (custom weights available) |

| Roll Width | 1.0m, 1.3m, 1.5m, 2.1m, 2.5m (custom widths available) |

| Thickness | 0.35 mm — 1.2 mm (depends on coating weight) |

| Tensile Strength (warp/weft) | ≥ 2000 N / 1500 N (depending on base cloth) |

| Tear Strength | ≥ 200 N (Trapezoid ASTM D4533 / ISO equivalent) |

| Hydrostatic Pressure | ≥ 2000 mm H₂O (100% waterproof) |

| Fire Rating | B1 (EN 13501-1), NFPA-701, CPAI-84 options |

| Temperature Range | -40°C to +80°C (formulation dependent) |

| Finish | Glossy / Matte / Anti-slip / Printable top coat |

| Surface Treatment | Anti-mildew, anti-static, UV stabilizer, anti-UV coating |

| Packing | Standard export roll packing; core diameters 50mm/76mm; wooden pallet or fumigated pallet for FCL |

Available Product Colors

Standard color options are suited to truck fleets, advertising and industrial applications. Custom Pantone matching is available for large orders.

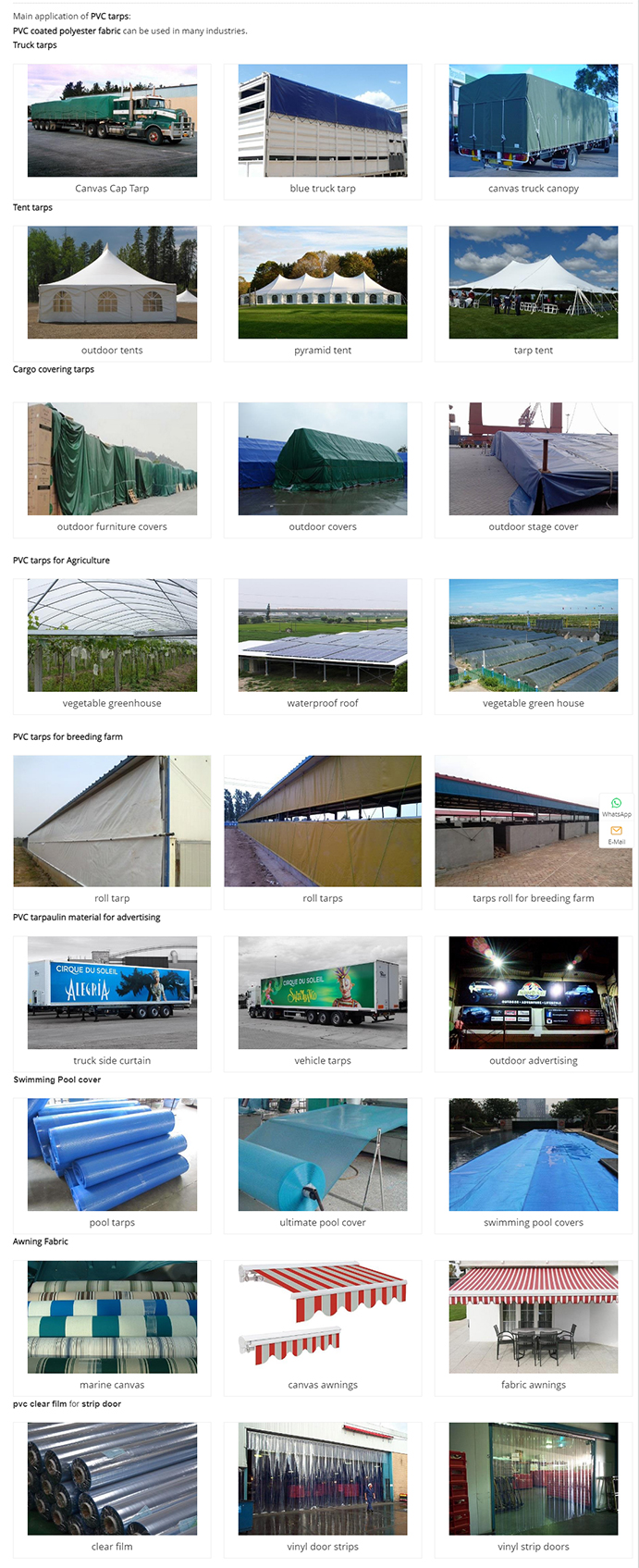

Typical Applications

DERFLEX PVC tarpaulin is specified across many industries. Common uses include:

- Truck & Trailer Covers — robust side curtains, tarpaulin trailers and tautliner curtains.

- Outdoor Advertising — billboard banners, mesh banner facades and large-format digital prints.

- Industrial & Agricultural Covers — silage covers, equipment shelters, cargo covers.

- Event & Temporary Structures — marquee walls, tent fabrics and stage backdrops (flame retardant grades).

- Construction & Scaffolding Wraps — protective sheeting, weatherproofing and dust control.

- Pool Covers & Inflatable Products — heavy-duty coated fabrics with UV and chlorine resistance.

- Architectural Facades — tension fabric structures and membrane roofs.

Installation Precautions & Best Practices

Follow these recommendations to maximize lifespan and ensure warranty compliance.

Storage & Handling

- Store indoors, away from direct sunlight and heat sources. Ideal storage temperature: 10–30°C.

- Avoid prolonged storage with heavy loads on top of rolls to prevent deformation.

- Protect exposed edges during transport; use edge protectors on pallets.

Cutting & Welding

- Use sharp rotary knives or hot knives for clean edges.

- For permanent seams, hot air welding with compatible welding rods or hot-melt adhesives creates strongest joints.

- Test welding parameters (temperature, speed, nozzle) on scrap samples before full production.

Fixing & Tensioning

- Ensure uniform tension on truck curtains to prevent overstress at eyelets or welds.

- Use reinforced hems and steel eyelets for repeated loading cycles.

- For architectural membrane systems, consult DERFLEX support for recommended anchor spacing and seam design.

Cleaning & Maintenance

- Regularly remove grit and debris; wash with mild detergent and low-pressure water.

- Avoid solvent cleaners or abrasive brushes that can damage the top coat.

- Inspect welds and fixings periodically, especially after winter and extreme weather events.

Certifications & Test Reports

DERFLEX provides test documents and certificates to support project approvals:

- ISO 9001: Quality Management System

- ISO 14001: Environmental Management (selected plants)

- EN 13501-1 / B1: Flame retardancy on request

- NFPA-701: US event fabric standard

- ASTM & ISO Mechanical Tests: Tensile, tear, hydrostatic pressure and colorfastness

- RoHS / REACH: Chemical compliance documentation on request

Full third-party lab reports and certificates issued per lot are available for purchase or provided for large project orders.

Why Choose DERFLEX PVC Tarpaulin

- Manufacturing Expertise: Proven coating lines and experienced technicians specialized in heavy-duty tarpaulin production.

- Custom Solutions: Tailored coatings, weights, colors and finishing for your exact application.

- Stringent QC: In-process inspection, roll-testing and factory QA documentation for each shipment.

- Global Logistics: Export packaging, FCL/LCL options and support for US import documentation.

- Technical Support: Application engineering, welding parameters, and installation guidance from our technical team.

Sold To Countries

DERFLEX tarpaulins are exported worldwide. Representative markets include:

- United States & Canada

- United Kingdom, Germany, France, Netherlands

- Middle East: UAE, Saudi Arabia, Qatar

- Australia & New Zealand

- South Africa & sub-Saharan Africa

- Latin America: Brazil, Mexico, Chile

- Japan & South Korea

Frequently Asked Questions

What is PVC tarpaulin and how is it made?

PVC tarpaulin is a synthetic coated fabric made by laminating or coating polyester base cloth with PVC plastisol or PVC-PU blends. The process produces a waterproof, durable sheet suitable for covers, banners and shelters. DERFLEX combines high-tenacity polyester with formulated PVC coatings and optional top coats for printing or anti-slip finishes.

Is DERFLEX PVC tarpaulin suitable for truck covers in the USA?

Yes. Our truck-grade tarpaulin fabrics are designed for high tensile strength, abrasion resistance and UV stability. We supply side curtains, top tarps and rear flaps to logistics and transport customers across North America.

Can DERFLEX tarpaulin be printed with high-resolution graphics?

Yes — printable topcoat options are available for solvent, eco-solvent and UV digital printing. We recommend pre-production tests to set ink profiles and curing parameters for optimal colorfastness and adhesion.

What are the recommended welding methods for seams?

Hot air welding with compatible welding rods, high-frequency welding for certain laminated composites, and hot-melt welding are commonly used. Welding parameters should be validated on sample swatches before production.

How do I request samples or technical datasheets?

Contact our sales team via DERFLEX contact page or email our North America representative. Provide application details, preferred weight and color to expedite sample selection.

Relevant Keywords (for search & specification)

PVC Tarpaulin USA, PVC tarpaulin fabric, truck tarpaulin USA, PVC billboard fabric, waterproof tarpaulin, PVC coated fabric, heavy duty tarpaulin, printable PVC banner, flame retardant tarpaulin, tarpaulin manufacturer.