Sustainable Tarpaulins – Eco-Friendly Industrial Cover Solutions

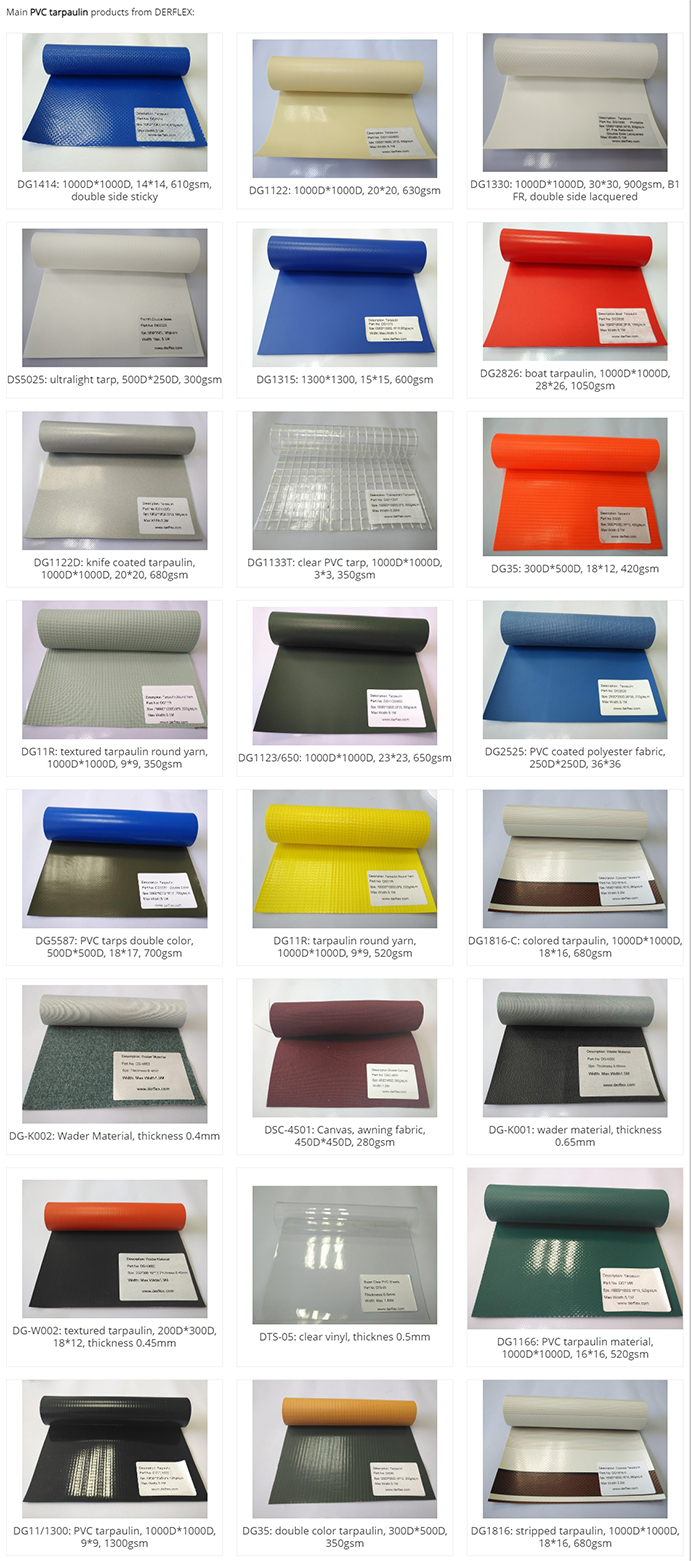

Manufacturer: DERFLEX

Official Website: https://www.derflex.com

Introduction to Sustainable Tarpaulins

As global industries move toward environmentally responsible manufacturing, Sustainable Tarpaulins have become a critical component in reducing environmental impact without compromising performance. DERFLEX sustainable tarpaulins are designed to meet modern sustainability standards while delivering exceptional durability, weather resistance, and long-term cost efficiency.

Unlike conventional tarpaulins that prioritize low upfront cost over lifecycle performance, DERFLEX focuses on eco-design, material optimization, and extended service life. This approach significantly reduces waste, resource consumption, and carbon footprint across the product lifecycle.

What Makes a Tarpaulin Sustainable?

Sustainability in tarpaulin manufacturing goes beyond recycled materials. At DERFLEX, sustainable tarpaulins are defined by a comprehensive framework that includes:

- Optimized PVC formulations with reduced environmental impact

- High-tenacity base fabrics that extend service life

- Recyclable and reusable material structures

- Lower maintenance and replacement frequency

- Compliance with international environmental standards

By increasing durability and reducing waste, sustainable tarpaulins deliver long-term ecological and economic value.

DERFLEX Sustainable Tarpaulin Materials

Eco-Optimized PVC Coating

DERFLEX uses advanced PVC coating technology engineered to reduce material consumption while maintaining tensile strength, flexibility, and weather resistance. These coatings are designed for:

- Extended UV resistance

- Reduced plasticizer migration

- Improved recyclability

- Lower VOC emissions during production

High-Tenacity Polyester Base Fabric

The foundation of a sustainable tarpaulin is its base fabric. DERFLEX utilizes high-tenacity polyester yarns that provide superior tear resistance and dimensional stability, reducing premature failure and replacement.

Optional Recycled Content

For selected applications, DERFLEX offers tarpaulins incorporating recycled polyester yarns or reprocessed PVC compounds, helping clients meet sustainability and ESG targets.

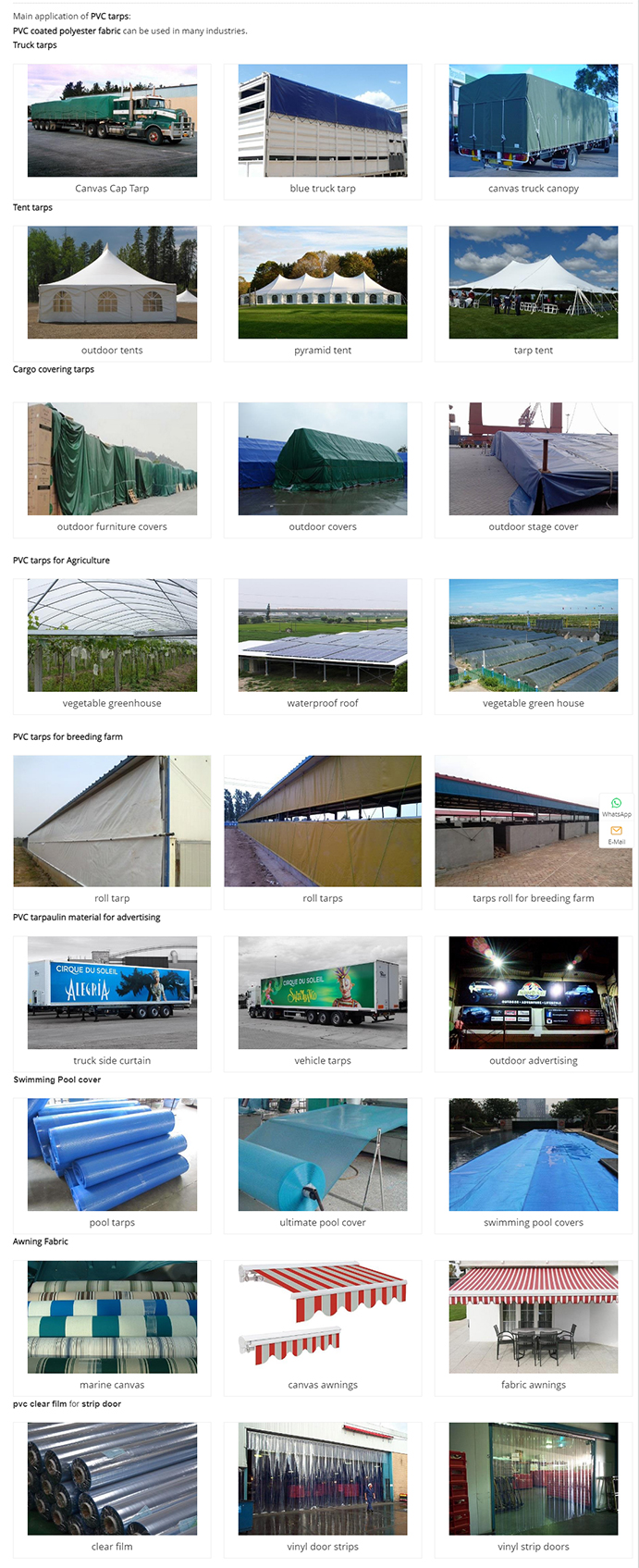

Applications of Sustainable Tarpaulins

Transportation & Logistics

Sustainable tarpaulins are widely used in truck covers, trailer side curtains, and cargo protection systems. Long service life reduces fleet downtime and material waste.

Construction & Infrastructure

In construction environments, DERFLEX sustainable tarpaulins provide reliable weather protection while aligning with green building practices and environmental regulations.

Agriculture & Farming

Agricultural tarpaulins for silage covers, crop protection, and greenhouse applications benefit from eco-friendly formulations and resistance to chemicals and UV exposure.

Industrial & Architectural Structures

Sustainable tarpaulins are increasingly used in tensile structures, temporary warehouses, and industrial enclosures where durability and environmental responsibility are equally critical.

Key Performance Advantages

- Longer service life reduces material waste

- Excellent UV, weather, and abrasion resistance

- High tear and tensile strength

- Lower total cost of ownership

- Compliance with global sustainability initiatives

Manufacturing Expertise & Quality Control

With decades of experience in coated fabric manufacturing, DERFLEX integrates sustainability into every stage of production. From raw material sourcing to coating, laminating, and finishing, strict quality control ensures consistent performance.

Our production facilities follow internationally recognized management systems, ensuring traceability, consistency, and environmental responsibility.

Compliance & Environmental Standards

DERFLEX sustainable tarpaulins are engineered to comply with key international standards, including:

- REACH compliance

- RoHS directives

- Low-VOC material requirements

- Custom regional environmental regulations

Customization & OEM Solutions

DERFLEX offers extensive customization options for sustainable tarpaulins, including:

- Custom thickness and weight

- Color matching and branding

- Flame retardant or anti-static properties

- Special surface finishes

- OEM and private label manufacturing

Why Choose DERFLEX as Your Sustainable Tarpaulin Manufacturer?

DERFLEX is recognized globally as a trusted manufacturer of high-performance coated fabrics and tarpaulins. Our commitment to sustainability is driven by engineering excellence, not marketing claims.

- Decades of coated fabric expertise

- Advanced R&D and material innovation

- Global supply capability

- Reliable long-term partnership

Frequently Asked Questions (FAQ)

Are sustainable tarpaulins as durable as traditional tarps?

Yes. DERFLEX sustainable tarpaulins are engineered for equal or superior durability, with extended service life that reduces overall environmental impact.

Can sustainable tarpaulins be recycled?

Many DERFLEX tarpaulin structures are designed for recyclability, depending on application and regional recycling infrastructure.

Do eco-friendly tarpaulins cost more?

While initial costs may vary, sustainable tarpaulins typically offer lower total cost of ownership due to longer lifespan and reduced replacement frequency.