Professional Tarp Manufacturer — Factory Direct Tarpaulins by DERFLEX

As an experienced tarp manufacturer and OEM tarpaulin factory, DERFLEX supplies a full portfolio of tarpaulin solutions — from lightweight PE tarps to heavy-duty PVC-laminated canvas, truck tarps and specialized industrial covers. We combine production scale with customization, quality control, and export logistics to serve distributors, OEMs and direct industrial customers worldwide.

About DERFLEX — Experienced Tarp Manufacturer

DERFLEX has operated advanced production lines for tarpaulin products for more than a decade. Our integrated facilities cover weaving, lamination, CNC cutting, welding and finishing. We pride ourselves on:

- Deep technical expertise in PVC lamination and coated fabrics

- Robust OEM workflows for repeatable, large-volume contracts

- Responsive sample and prototyping processes to reduce time-to-market

- Compliance with international quality and testing standards

Product Range — Full Tarpaulin Portfolio

DERFLEX manufactures a wide range of tarpaulins to serve different markets and applications:

- PVC-Laminated Tarps — Heavy duty, waterproof, and durable for truck covers, containers, and industrial protection.

- Canvas Tarps — Treated cotton or polyester canvas for temporary shelters, events and breathable covers.

- PE / PP Tarps — Cost-effective solutions for agricultural and general-purpose covering.

- Truck & Trailer Tarpaulins — Curtain-side, roll-top, and bespoke truck covers with reinforced edges and fastenings.

- Industrial Covers — Equipment covers, insulation covers, welding screens and machine protection covers.

- Marine Tarps — Anti-salt treated and UV stabilized for coastal & marine applications.

- Specialty & Event Tarps — Flame-retardant fabrics, printed marquees, and tenting solutions.

Each product line can be specified with custom accessories including grommets, hems, webbings, ratchets, buckles and printed logos.

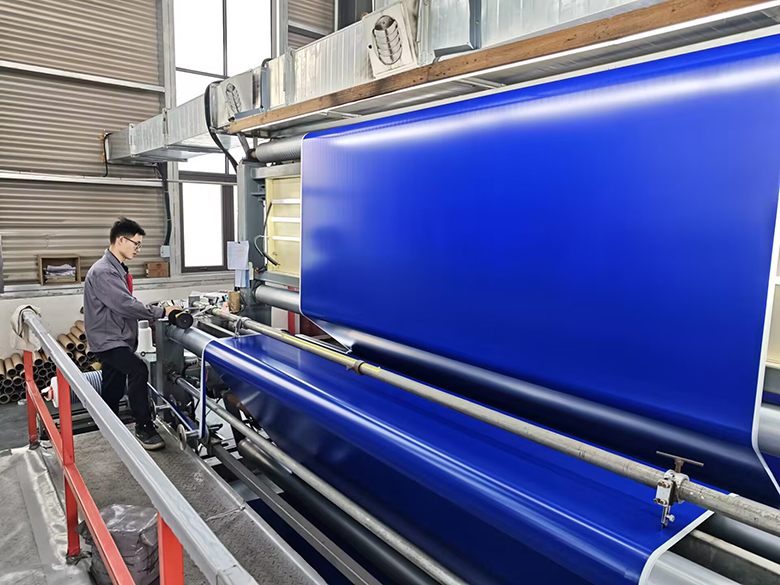

Manufacturing Capabilities

Our factory is equipped to handle high-volume OEM production while maintaining precise quality control:

- High-capacity coating & lamination lines (PVC, PU)

- Automatic and manual welding stations (hot air, RF, hot wedge)

- CNC fabric cutting tables and automated folding/seaming machines

- Screen printing and digital printing lines for logos and safety markings

- In-house metal fitting lines for grommets and buckles

We accommodate both roll-to-roll production for continuous runs and batch processing for bespoke orders, with dedicated lines for marine-grade and flame-retardant products.

Quality Control & Testing

Quality control is integral to our manufacturing process. Key QC measures include:

- Incoming raw material inspection and traceability

- In-line thickness measurement and lamination adhesion tests

- Tensile, tear and hydrostatic head tests on finished samples

- UV aging and accelerated weathering tests

- Third-party SGS testing available for contract orders

For large contracts we provide batch certificates, QA reports and sample retentions as part of our acceptance criteria.

OEM & Customization Services

DERFLEX specializes in OEM manufacturing and long-term supply agreements. Our OEM services include:

- Custom materials and weight (GSM) selection

- Color matching and custom pigments

- Printed logos, instructions, and barcode labels

- Custom grommet patterns, hems, webbings and pockets

- Private labeling, packaging, and packing lists tailored to distributor needs

We work closely with buyer technical teams to develop prototypes, validate performance, and iterate designs before mass production to ensure alignment with brand quality expectations.

Technical Specifications & Options

| Specification | Typical Range / Options |

|---|---|

| Base Fabric | Polyester weave (high tenacity), cotton canvas, PP/PE woven |

| Lamination/Coating | PVC (single/double side), PU, acrylic, waxed finishes |

| Fabric Weight | 150–1200 g/m² |

| Thickness | 0.15–1.5 mm |

| Hydrostatic Head | >1500 mm (typical for waterproof tarps) |

| Grommet Materials | Brass, nickel-plated, stainless steel |

| Edge Reinforcement | Rope-in hem, double fold, webbing |

| Printing | Screen print, digital print, reflective inks |

Contact our technical sales team to request a detailed technical datasheet for your selected material and construction.

Applications & Industries Served

DERFLEX tarps are used across diverse industries. Common applications include:

- Logistics and transportation (truck & trailer covers)

- Construction and scaffolding protection

- Agriculture (hay covers, silage protection, equipment covers)

- Marine and shipbuilding

- Events and exhibitions (tents, marquees)

- Industrial machinery and insulation covers

- Retail and promotional (branded covers, printed tarps)

Each sector has specific performance requirements—our engineers help specify the right material and accessory package for the end-use environment.

Case Studies — Proven Performance

Fleet Retrofit — EU Logistics Operator

DERFLEX designed reinforced curtain-side tarps for a European fleet. The result was a 20% reduction in weather-related cargo claims and a 14% lower total cost of ownership due to extended service intervals.

Agricultural Packaging Partner — South America

A packaging distributor sourced UV-stabilized PE tarps for seasonal crop protection. DERFLEX optimized fabric weight and UV additives to meet local climatic conditions and extended field life.

Industrial OEM — Machinery Covers

A manufacturing OEM required machine covers with exact-fit patterns and flame-retardant treatment. DERFLEX supplied prototype samples, revised fitment, and delivered a 2-year supply contract after validation testing.

Ordering, Packaging & Shipping

We support worldwide shipping and offer flexible packaging solutions to meet importer requirements:

- Standard packs: rolls, folded tarps in polybags, boxed pallets

- Export packing: fumigated pallets, wooden crates for heavy items

- Incoterms: FOB Shanghai, CIF, DDP available per contract

- Sample policy: samples available for testing; sample charges refunded with bulk orders in many cases

For large projects, DERFLEX can arrange consolidated shipping and local warehousing in target markets to reduce lead times and logistics costs.

Sustainability & Compliance

DERFLEX is committed to sustainable manufacturing practices. Measures include:

- Energy management and waste reduction programs in factories

- Optimization of material usage to reduce scrap

- Offering recyclable material options where feasible

- Providing guidance on end-of-life disposal and recycling partners

We also ensure product compliance with customer-specified regulations and can assist with documentation for import and market entry (e.g., testing, MSDS, RoHS where applicable).

Frequently Asked Questions

Q: What is the minimum order quantity (MOQ)?

A: MOQ varies by product and customization. Stock items often start at 1 pallet. Custom-engineered tarps typically have higher minimums — contact sales for exact figures based on your specification.

Q: Do you provide samples for testing?

A: Yes. We provide samples for evaluation; sample charges may apply and are often credited back against bulk orders.

Q: Can you meet specific fire-safety standards?

A: Flame-retardant treatments are available. Specify the required standard (e.g., NFPA, BS EN) and we will confirm capability and testing options.

Q: How do you ensure consistent quality in large OEM runs?

A: Through controlled material sourcing, inline monitoring systems, sample retention, and batch testing. We provide AQ reports and accept inspection protocols from buyer QC teams.

Contact DERFLEX — Tarp Manufacturer & OEM Partner

To request a quote, schedule a factory visit, or discuss long-term OEM supply, contact our sales and technical teams:

Email: sales@derflex.com

Phone: +86-021-54361792 / +86-21-54361798

Factory & Export: Shanghai DER New Material Co., Ltd

Website: https://www.derflex.com