Tarpaulin Material Glossary: PE, HDPE, LDPE, PVC, Oxford

A practical, SEO-friendly guide comparing common tarpaulin materials — what they are, technical specs, best uses, installation tips, and how to choose the right tarpaulin for your project.

Overview: Why Material Choice Matters

Tarpaulins are more than “big pieces of fabric.” The base material defines durability, weather-resistance, printability, weldability, weight and cost. This glossary covers the five most used materials in modern tarpaulins: PE (polyethylene), HDPE (high-density polyethylene), LDPE (low-density polyethylene), PVC (polyvinyl chloride), and Oxford cloth. Understanding these materials helps you pick the right tarp for transport, advertising, construction, agriculture or temporary shelters.

Quick Material Snapshot

| Material | PE — economical woven polyethylene, often laminated. Good for temporary covers, pallet covers, and lightweight tarps. |

|---|---|

| HDPE | HDPE — stiffer, higher tensile strength. Used for heavy-duty woven tarps, shade netting and erosion control. |

| LDPE | LDPE — more flexible and softer than HDPE; used in films and membrane applications where flexibility is key. |

| PVC | PVC coated/laminated polyester — premium choice. Excellent strength, printability, weldability and long-term outdoor performance. Common in truck covers, awnings and printed banners. |

| Oxford | Oxford cloth — woven polyester or nylon with PU coating; popular for lightweight reusable tarps, backpacks, tents and canopies. |

Material Profiles — In-Depth

PE (Polyethylene) Tarpaulin

What it is: Woven polyethylene fabric usually laminated with a thin PE film for waterproofing.

| Typical Specs | Weight: 60–250 gsm (light to medium); Thickness: 0.08–0.35 mm; Standard widths: 1.2–5.1 m; Tensile: moderate; UV treatment: optional. |

|---|---|

| Key Features | Very low cost, lightweight, waterproof, rot-resistant, limited UV life when untreated. |

| Common Applications | Temporary ground covers, pallet covers, emergency shelters, packaging, low-cost truck covers. |

HDPE (High-Density Polyethylene)

What it is: Stronger woven polyethylene with higher molecular density—stiffer and more tear-resistant than standard PE.

| Typical Specs | Weight: 150–400 gsm; Thickness: 0.15–0.6 mm; Standard widths: 1.2–4.0 m; High tensile & tear resistance; Often UV-stabilized. |

|---|---|

| Key Features | Better mechanical strength, longer service life outdoors (with UV treatment), cost-effective alternative to coated fabrics. |

| Common Applications | Shade cloths, heavy-duty pallet and cargo covers, geomembranes, temporary fencing and agricultural covers. |

LDPE (Low-Density Polyethylene)

What it is: A softer, more flexible form of polyethylene commonly used as films and flexible membranes.

| Typical Specs | Weight: 40–200 gsm (film/laminate); Thickness: 0.02–0.2 mm; Flexible, cold-resistant. |

|---|---|

| Key Features | Excellent conformability, good cold-weather performance, used where bendability and sealability are required. |

| Common Applications | Liners, vapor barriers, pond liners (with special blends), and protective films. |

PVC (Polyvinyl Chloride) Coated / Laminated Fabric

What it is: Woven polyester or nylon base coated/laminated with PVC on one or both sides. Recognized as premium tarpaulin material.

| Typical Specs | Weight: 300–1200 gsm (light to ultra heavy-duty); Thickness: 0.3–1.5 mm; Widths up to 5.1 m (single piece); Tensile: high; Tear: high; UV & chemical treatments available. |

|---|---|

| Key Features | Exceptional tensile and tear strength; weldable (high-frequency/hot-air); excellent printability for full-color graphics; long service life; fire-retardant options. |

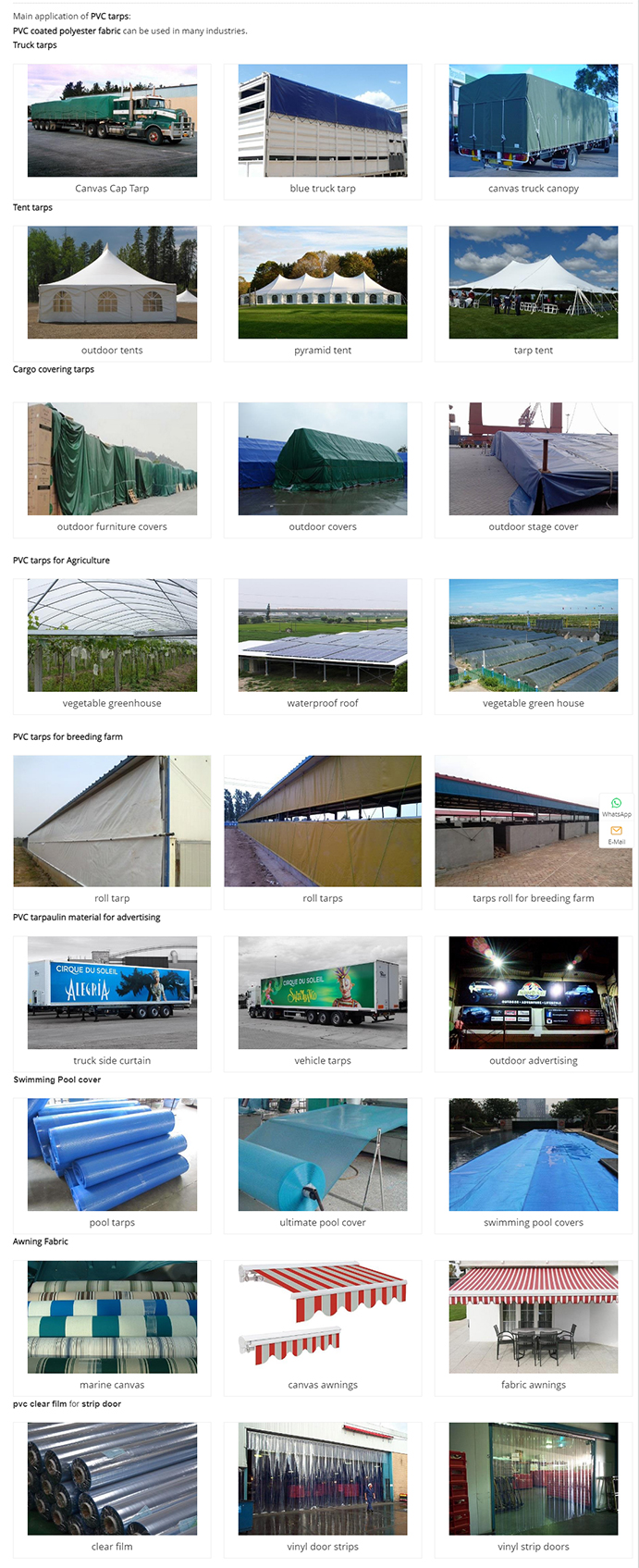

| Common Applications | Truck tarpaulins, side curtains, heavy-duty shelters, tensile membranes, printed advertising banners, industrial curtains and pond liners (special grades). |

Oxford Fabric (PU Coated)

What it is: Woven nylon or polyester (often 210D, 420D etc.) finished with a PU (polyurethane) coating.

| Typical Specs | Weight: 150–600 gsm equivalent (depending on denier & coating); Thickness: variable; Lightweight and packable. |

|---|---|

| Key Features | Lightweight, flexible, easy to sew, good water resistance with PU finish, excellent for consumer products. |

| Common Applications | Tents, backpacks, light-duty awnings, furniture covers, canopies, and protective bags. |

Choosing the Right Tarpaulin Material — Practical Guidelines

- Budget & lifespan: If cost is primary and use is short-term, PE can be ideal. For long-term outdoor use choose PVC.

- Strength & weldability: PVC is best where welded seams and heavy mechanical strength are required (truck curtains, industrial shelters).

- Printability & branding: Choose PVC for crisp, full-color printing that endures outdoors.

- Flexibility & cold use: LDPE or specially formulated PVC maintains flexibility at low temperatures.

- Consumer/lightweight use: Oxford fabrics balance appearance, weight and moderate weather resistance.

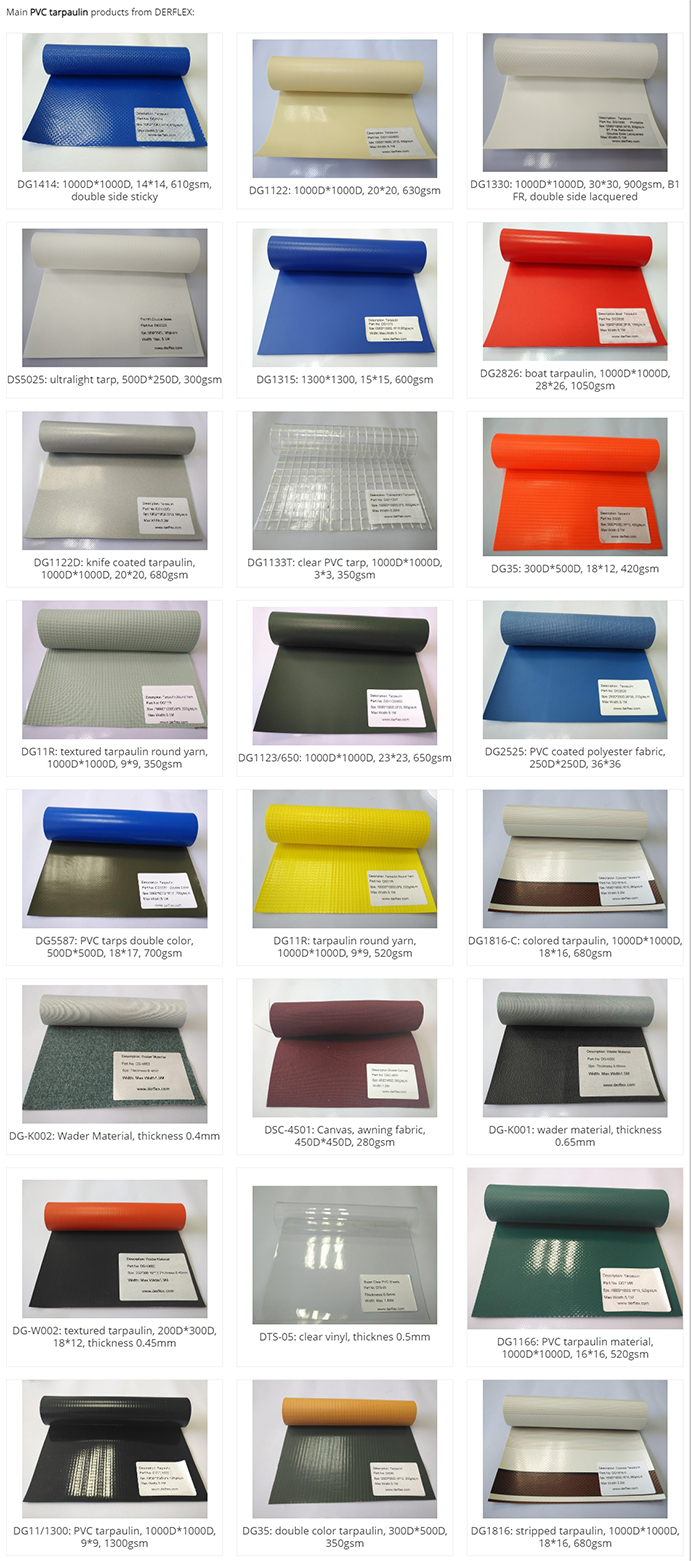

DERFLEX Product Introduction & Key Offerings

DERFLEX (Anhui DER New Materials Co., Ltd.) is a specialist manufacturer of coated fabrics and tarpaulin materials. With integrated production lines for weaving, coating, lamination and printing, DERFLEX supplies PE, HDPE, LDPE films, premium PVC coated fabrics and Oxford cloth products tailored for industrial, agricultural, transportation and advertising markets. Our portfolio includes welded PVC tarpaulin rolls, printable banner fabrics, and custom membrane solutions.

Request custom samples and technical datasheets for material grades by visiting our Request A Quote page: https://www.derflex.com/Request-Quote.html

Installation Precautions & Best Practices

- Measure twice, cut once: always confirm finished dimensions and seam allowances before fabrication.

- Use the correct joining method: HDPE & PE are typically sewn or heat-sealed; PVC is ideally welded (HF or hot-air); Oxford fabrics are sewn with PU seam sealing if waterproofing is required.

- Avoid excessive tension: over-stretching causes seam failure and premature wear.

- Protect edges and corners: reinforce high-strain points with webbings, plates or hem tapes.

- Clean and maintain: remove dirt and salt deposits; follow manufacturer cleaning instructions to preserve coatings and colors.

Sold to Countries & Global Reach

DERFLEX exports tarpaulin materials worldwide. Key markets include Europe (Germany, UK, France), North America (USA, Canada), Australia, South America (Brazil), Middle East (UAE, Saudi Arabia), Southeast Asia and Africa. We adapt packaging, certifications and documentation to meet local requirements and shipping conditions.

FAQs — Tarpaulin Material Comparison

Q: Which tarpaulin material lasts longest outdoors?

A: Properly formulated PVC coated fabrics with UV stabilizers typically offer the longest useful life for outdoor, high-stress applications.

Q: Can PVC be recycled?

A: PVC recycling is possible but depends on local facilities and the presence of additives. DERFLEX offers guidance on end-of-life options and recyclable grades where available.

Q: Are PE and HDPE weldable?

A: PE can be hot-air welded with appropriate machinery and temperature control, but HDPE woven tarps are more commonly sewn and taped. PVC is the easiest to weld reliably.

Q: Which material is best for printed advertising banners?

A: PVC coated fabrics (matte or glossy) offer the best print clarity, ink compatibility (solvent, eco-solvent, UV, latex) and durability.

Q: Do you supply material certificates and test reports?

A: Yes — DERFLEX provides ISO quality documentation, SGS test reports (tensile, tear, UV aging), REACH/RoHS declarations and fire-retardant certificates upon request.

Relevant Keywords & Long-Tail Search Phrases

tarpaulin material glossary, PE tarpaulin vs PVC, HDPE tarpaulin uses, LDPE pond liner, PVC coated tarpaulin specifications, oxford fabric tarpaulin, best material for truck tarpaulin, heavy duty PVC tarpaulin 650gsm, printable tarpaulin for banners, waterproof tarpaulin material comparison, derflex tarpaulin materials.