Technical Coated Fabrics Manufacturer | PVC & Industrial Performance Textiles

DERFLEX is one of China’s leading manufacturers of technical coated fabrics, offering a full range of industrial-grade textile solutions engineered for unmatched durability, strength, chemical resistance, and performance under extreme conditions. With 20+ years of expertise, advanced coating technology, and comprehensive OEM/ODM support, DERFLEX supplies global industries with reliable coated materials for transportation, construction, protective equipment, marine applications, agricultural covers, and structural membranes.

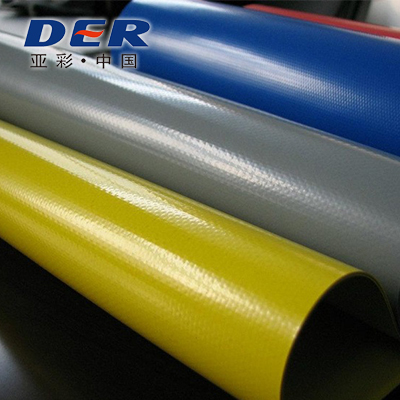

Our technical coated fabrics are developed using high-strength base cloth (polyester, nylon, fiberglass, aramid, etc.) combined with advanced coatings such as PVC, TPU, TPE, PE, acrylic, and silicone. This creates engineered materials with superior weather resistance, waterproofing, dimensional stability, and custom mechanical properties.

What Are Technical Coated Fabrics?

Technical coated fabrics are engineered textiles created by applying specialized polymer coatings to a selected substrate to enhance its physical, chemical, and environmental performance. These fabrics are designed for industrial applications where standard fabrics are not strong or durable enough.

Typical Components

- Base fabric: polyester, nylon, fiberglass, aramid, composite weaves

- Coating materials: PVC, TPU, TPE, acrylic, silicone rubber, neoprene, PU

- Finish options: lacquer, anti-UV layer, flame-retardant treatment, anti-mildew, anti-static

Through advanced coating technology, DERFLEX develops technical fabrics that deliver precise performance characteristics required by engineering, industrial, and outdoor applications.

Key Features of DERFLEX Technical Coated Fabrics

1. Extreme Durability & Mechanical Strength

Made with high-tenacity base cloth and reinforced coating systems, DERFLEX technical fabrics offer excellent tensile strength, tear resistance, abrasion resistance, and long-lasting dimensional stability.

2. Waterproof, Weatherproof & UV Resistant

Engineered for permanent outdoor exposure, our coated fabrics provide complete protection against heavy rain, UV radiation, temperature fluctuations, mold, and outdoor contaminants.

3. Chemical & Oil Resistance

Specialized coatings make the materials resistant to oils, fuels, chemicals, and industrial liquids—ideal for harsh environments.

4. Customizable Formulations

DERFLEX develops tailor-made coated fabrics for OEM partners based on industry requirements including color, thickness, surface finish, coating material, flame retardancy (FR), anti-static functions, and more.

5. Long Service Life

Our products are designed for 5–15 years of reliable use depending on the application and environment.

Technical Specifications

| Base Fabric Options | PES, Nylon, Fiberglass, Aramid, Composite Textiles |

|---|---|

| Coating Materials | PVC, TPU, PE, TPE, Silicone, Acrylic, PU |

| Weight Range | 200 gsm – 1800 gsm |

| Width | 1m – 3.2m (customizable) |

| Temperature Tolerance | -40°C to +85°C (material dependent) |

| Finish | Glossy, matte, lacquered, anti-UV, FR, anti-static |

| Color | Any Pantone color |

| OEM/ODM | Available |

Applications of Technical Coated Fabrics

1. Transportation & Logistics

- Truck tarpaulin systems

- Side curtains / container covers

- Cargo protection

- Railway and shipping covers

2. Industrial & Engineering

- Machine covers

- Protective partitions

- Inflatable structures

- Containment systems

3. Construction & Architecture

- Tensile membrane structures

- Building wraps

- Scaffolding covers

- Temporary shelters

4. Agriculture & Farming

- Greenhouse covers

- Grain storage covers

- Livestock protection

- Water tanks & liners

5. Marine & Outdoor

- Boat covers

- Marine upholstery

- Outdoor tents

- Sunshade structures

About DERFLEX – Professional Manufacturer of Technical Coated Fabrics

Founded in 2001, DERFLEX is a global supplier of PVC coated fabrics and industrial textiles with strong R&D capacity and advanced production equipment including knife-coating lines, lamination lines, calendering systems, and precision weaving machines.

Our technical coated fabrics are exported to 120+ countries, serving distributors, OEM factories, engineering contractors, logistics companies, and military and industrial clients worldwide.

Why Choose DERFLEX?

- 20+ years manufacturing experience

- Full customization for OEM/ODM projects

- Strict quality control: ISO9001, SGS, REACH compliance

- Competitive factory pricing

- Fast delivery & global shipping support

Technical Coated Fabrics – FAQ

1. What is the difference between coated fabrics and laminates?

Coated fabrics are created by applying liquid polymer onto the base cloth and curing it, while laminates fuse pre-formed layers together. Coated fabrics generally offer better adhesion and durability.

2. Can DERFLEX manufacture custom formulations?

Yes. DERFLEX specializes in OEM production including custom coating materials, FR grade, thickness, mechanical strength, width, and surface treatments.

3. Are technical coated fabrics suitable for outdoor permanent use?

Yes. Our PVC and TPU coated fabrics are engineered for long-term outdoor use with UV-resistant, waterproof, and anti-mildew properties.

4. Do you offer sample testing?

DERFLEX provides free samples for quality evaluation before mass production.

5. How long is the service life?

Service life varies by material: PVC coated fabrics typically last 5–10 years; TPU and silicone-coated fabrics can last 10–15 years.