TPU Materials Manufacturer – High-Performance TPU Films & Coated Fabrics

DERFLEX is a professional TPU materials manufacturer specializing in precision-engineered thermoplastic polyurethane films and coated textiles. Our TPU films and TPU fabrics are widely used in outdoor equipment, inflatables, medical protection, marine structures, industrial sealing, flexible storage tanks, protective covers, waterproof bags, high-pressure inflatable products, and safety gear.

What Are TPU Materials?

Thermoplastic Polyurethane (TPU) is an advanced polymer material known for its excellent flexibility, abrasion resistance, toughness, transparency, elasticity, and high-level waterproof performance. TPU combines the advantages of plastic and rubber, making it one of the most versatile and durable materials used in modern engineering, protective equipment, and inflatable structures.

DERFLEX manufactures TPU films, TPU-coated fabrics, TPU-laminated fabrics, and custom TPU composites that meet stringent industry requirements. With over 20 years of experience in industrial coated fabrics, DERFLEX ensures each TPU material delivers stable quality, reliable bonding strength, and long-term durability under extreme conditions.

Main TPU Material Categories

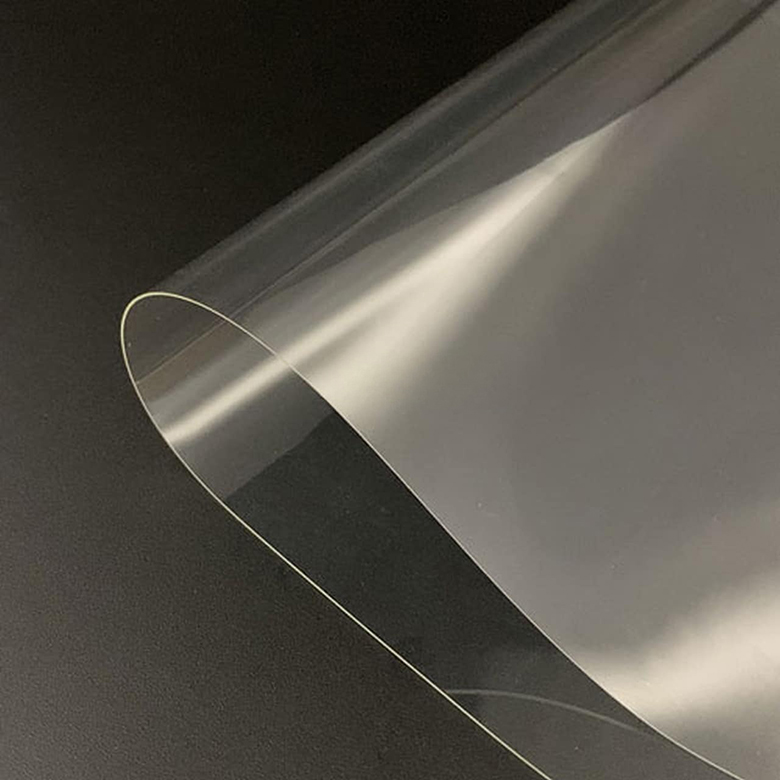

1. TPU Film

DERFLEX TPU films are available in polyether TPU and polyester TPU with a thickness range from 0.02–1.0 mm. These films offer excellent flexibility, optical clarity, and weldability, making them ideal for:

- Waterproof bags & outdoor gear

- Medical protection components

- Inflatable air structures

- Hydration bladders

- Protective protective films

2. TPU Coated Fabric

TPU-coated fabrics combine a strong base textile (such as polyester or nylon) with a TPU coating layer for enhanced waterproofing and tear resistance. This type is widely used for:

- Inflatable boats & kayaks

- Flexible water tanks & pillow tanks

- Safety air cushions

- High-pressure inflatable products

- Military and industrial protective covers

3. TPU Laminated Fabric

TPU-laminated fabrics are produced by laminating TPU films to textile substrates using hot melt technology. Advantages include:

- Strong bonding without solvents

- Higher elasticity and tensile strength

- Better chemical resistance

- Superior airtight and waterproof performance

4. Custom TPU Composites

DERFLEX offers customized TPU material solutions such as:

- Fire-retardant TPU composites

- High-pressure inflatable TPU materials

- Low-temperature-resistant TPU films

- Anti-microbial/anti-fungal TPU textiles

- UV-resistant TPU materials

Advantages of DERFLEX TPU Materials

1. Excellent Waterproof & Airtight Performance

TPU provides superior waterproof and airtight sealing, making it ideal for inflatable and sealing applications. It maintains integrity even under high pressure.

2. High Elasticity & Mechanical Strength

DERFLEX TPU films and fabrics maintain flexibility while resisting impact, bending, and tearing, ensuring long-term structural stability.

3. Abrasion & Puncture Resistance

Unlike PVC, TPU retains performance even under extreme conditions involving friction or impact.

4. Low Temperature Resistance (-45°C)

TPU materials remain soft in cold environments, suitable for snow sports equipment, winter outdoor gear, and cold-storage structures.

5. Eco-Friendly & Non-Toxic

TPU is **PVC-free**, recyclable, odorless, and compliant with:

- REACH

- RoHS

- ISO environmental standards

6. UV & Hydrolysis Resistance

Polyether TPU resists yellowing, moisture, and UV degradation, ensuring stable outdoor performance.

Applications of TPU Materials

With high flexibility, waterproofing, and chemical resistance, TPU materials are adopted in dozens of major industries.

Outdoor & Sports Industry

- Dry bags & waterproof backpacks

- Hydration bladders

- Inflatable tents

- Outdoor protective covers

Medical & Healthcare

- Medical air pressure cushions

- Protective TPU films

- Inflatable medical devices

Marine & Water Sports

- Inflatable kayaks

- Paddle boards

- Buoyancy devices

Industrial & Construction

- Flexible storage tanks

- High-pressure air ducts

- Industrial sealing layers

Safety & Military

- Bullet-resistant inflatable cushions

- Safety protection films

- Heat-resistant protective fabrics

Technical Specifications of DERFLEX TPU Materials

| Item | Specification |

|---|---|

| Material Type | Polyester TPU / Polyether TPU |

| Thickness | 0.02–1.0 mm |

| Width | Up to 2.1 m |

| Hardness | 70A–95A |

| Tensile Strength | ≥ 35 Mpa |

| Temperature Resistance | -45°C to +80°C |

| Surface | Glossy / Matte / Customized |

| Available Colors | Transparent / Black / Army Green / Custom |

Why Choose DERFLEX as Your TPU Materials Manufacturer?

20+ Years of Industrial Fabric Manufacturing

DERFLEX has specialized in coated fabrics and polymer materials since 2001, delivering stable quality for global industrial clients.

Advanced Production Equipment

- High-precision TPU extruders

- Hot melt laminating machines

- Automatic coating lines

- High-pressure testing equipment

Strict Quality Control

- 100% raw material inspection

- Real-time online thickness monitoring

- Airtightness & waterproof testing

- Tensile and tear strength testing

Customized Engineering Solutions

We provide OEM and ODM service for TPU films and coated fabrics based on:

- Color

- Thickness

- Base fabric

- Coating weight

- Material hardness

- Surface finish

FAQ About TPU Materials

Is TPU better than PVC?

Yes. TPU is stronger, more flexible, more durable, and more environmentally friendly than PVC. It also performs better in cold temperatures and high-stress environments.

Can TPU be welded?

DERFLEX TPU films and fabrics can be welded using high-frequency welding, hot air welding, and high pressure bonding.

How long does TPU material last?

High-quality TPU such as DERFLEX materials can last 5–15 years depending on application and environmental conditions.

Is TPU safe?

TPU is non-toxic, odorless, and compliant with global safety standards. It contains no plasticizers or heavy metals.