Overview

Our vinyl tarpaulin fabric (commonly called PVC tarpaulin) is manufactured using a high-tenacity polyester base cloth and multi-layer PVC coating technology. Through advanced calendaring and lamination processes, DERFLEX produces tarpaulin materials with consistent thickness, excellent sealing performance, and outstanding weather resistance.

Key benefits

Product Specifications (Typical)

| Parameter | Typical Value / Options |

|---|---|

| Base Cloth | Polyester (high-tenacity): 1000D / 1100D / 1200D |

| Total Weight | 300gsm — 1200gsm (most common: 650gsm) |

| Coating | Single / Double-sided PVC; polymerized PVC compound with additives |

| Thickness | 0.35mm — 1.2mm (depending on gsm) |

| Tensile Strength | Warp: ≥2000 N/5cm — Weft: ≥1900 N/5cm (varies by grade) |

| Tear Strength | Cross cut tear resistance ≥200N |

| Hydrostatic Head | > 5000 mm (excellent waterproof rating) |

| Elongation | 5%—12% (controlled for dimensional stability) |

| Colour Fastness | Grade 4–5 (ISO methods with UV stabilizer) |

| Surface Finish | Matte, Semi-gloss, Gloss, or Textured (anti-slip) |

| Fire Rating (optional) | M2 (EN13501-1) / B1 (GB/T) / NFPA-RF options available |

| Printing Compatibility | Solvent / Eco-solvent / UV / Latex digital printing |

| Available Width | 1.0m — 5.1m (custom slitting & welding available) |

| Packing | Rolls with protective film & inner core; carton or wooden pallet packaging |

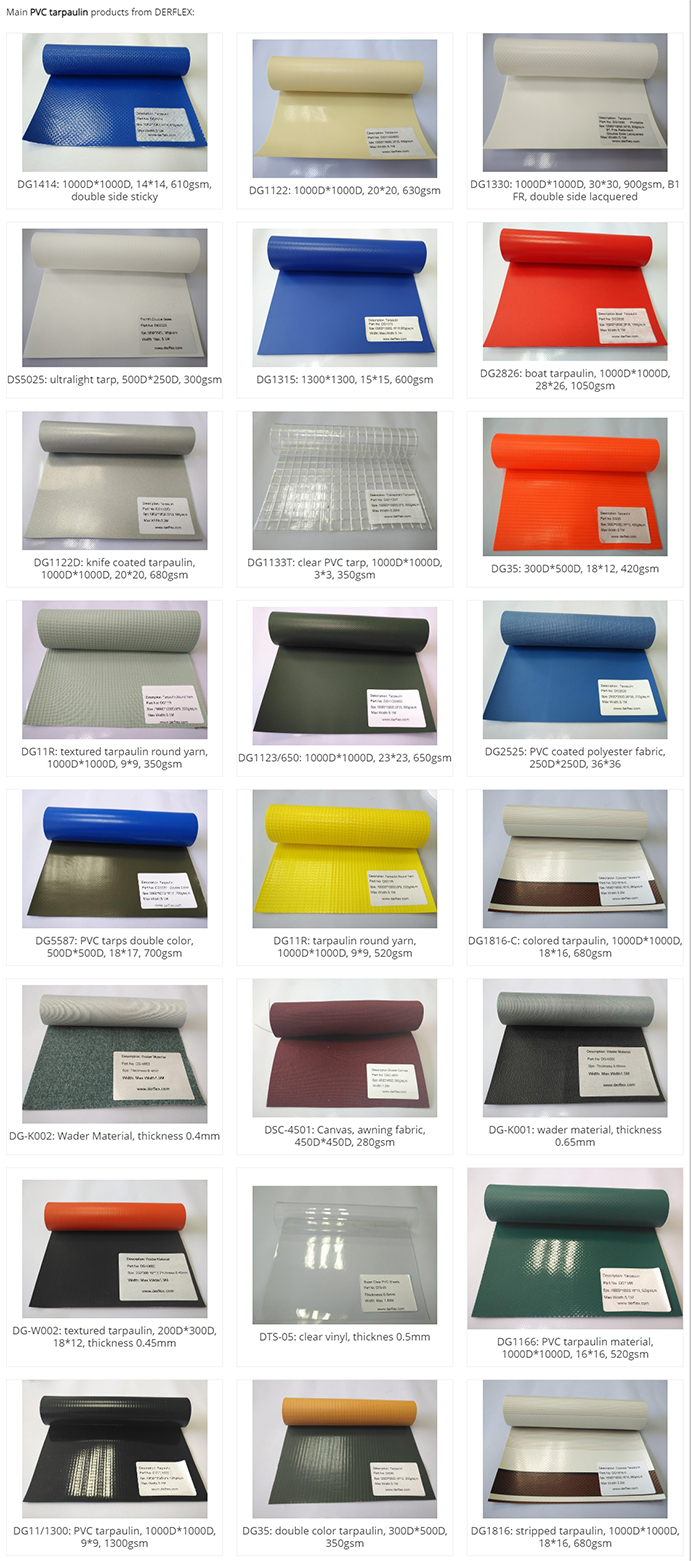

Product Colors & Surface Options

Standard and custom colors are available. Popular colors include:

Dark Blue, Ocean Blue, Forest Green, Traffic Red, Sun Yellow, White / Light Grey, Black.

Custom Pantone matching and dual-color constructions are available upon request.

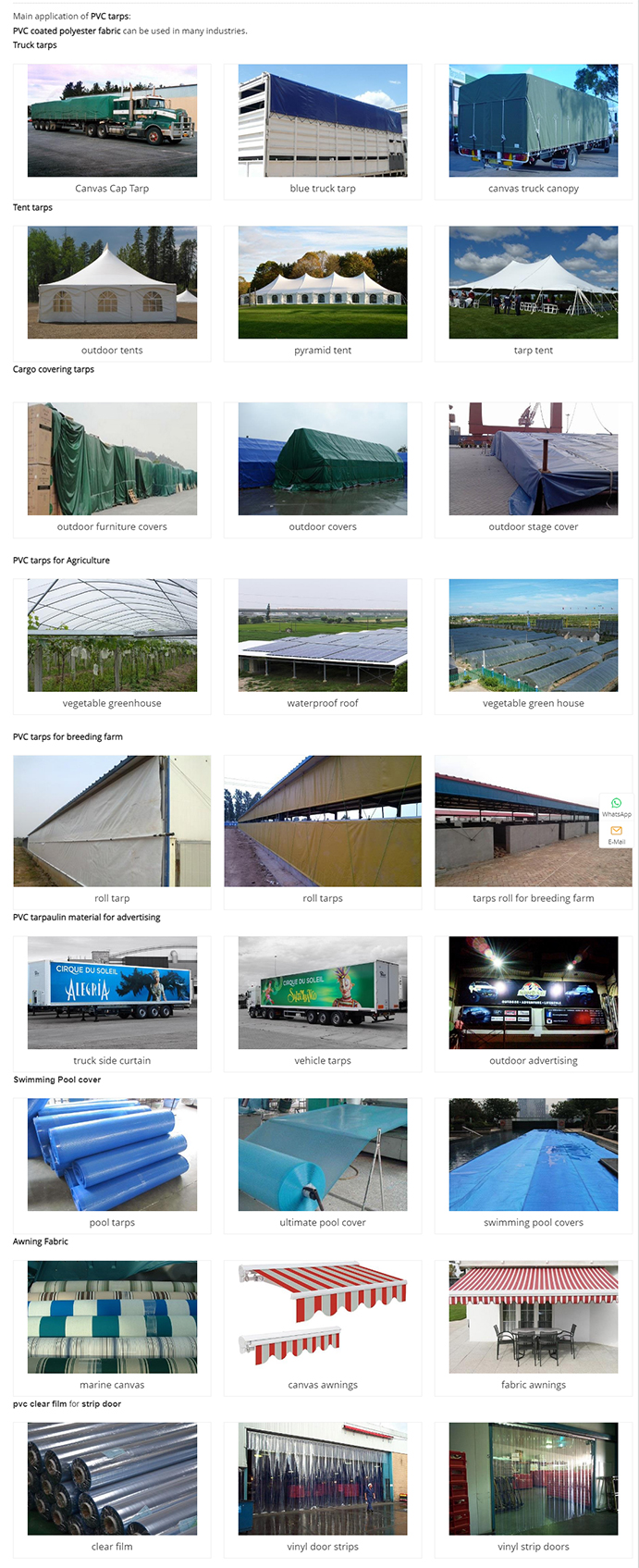

Common Applications

- Truck tarpaulins and trailer covers

- Outdoor tents and marquee fabric

- Industrial covers and equipment shelters

- Billboard and wide-format advertising banners

- Swimming pool covers and pond liners

- Inflatable structures and bounce houses (with safety-grade formulations)

- Agricultural covers and greenhouse curtains

- Architectural membrane and shade sails (with coated finish)

DERFLEX — Company Introduction & Commitment to Quality (Google EEAT)

DERFLEX is an established manufacturer of coated fabrics and technical membranes with decades of experience in polymer compounding, textile lamination and industrial finishing. Our R&D team, led by polymer chemists and textile engineers, continuously refines coating formulations and production processes to ensure product performance and regulatory compliance.

DERFLEX emphasizes expertise (technical R&D and lab testing), experience (years of large-scale production & global projects), authority (industry certifications and partnerships), and trustworthiness (transparent testing reports and traceable material sourcing).

Quality Assurance & Third-Party Testing

All batches pass rigorous in-house QC — including tensile & tear testing, hydrostatic pressure testing, accelerated UV ageing, and adhesion tests — and can be inspected by third-party laboratories (SGS, Intertek) on request. DERFLEX provides material safety data sheets (MSDS), technical data sheets (TDS) and sample test reports to support project bids and regulatory filings.

Certificates & Compliance

- ISO 9001: Quality Management System

- ISO 14001: Environmental Management (where applicable)

- SGS / Intertek Test Reports (mechanical, weathering, chemical)

- Oeko-Tex / REACH compliance for selected product lines

- Fire-retardant certificates to EN / GB / NFPA standards (optional)

Why Choose DERFLEX Vinyl Tarpaulin Fabric?

- Proven material science: proprietary PVC formulations for long-term durability and colour stability.

- Factory capacity & consistency: automated calendering and lamination lines ensure repeatable thickness and coating adhesion.

- Printing & finishing expertise: smooth and printable surfaces tailored for modern wide-format printers.

- Customization: bespoke colors, widths, coatings and fire-retardant treatments available.

- Global logistics: export experience, export documentation and consolidated shipping options for worldwide delivery.

Installation Precautions & Best Practices

Follow these guidelines to maximize lifespan and performance:

- Keep materials in original packaging until installation to prevent contamination and UV exposure.

- Store rolls flat or vertically in a dry, shaded place; avoid prolonged exposure to direct sunlight before installation.

- Use recommended seam-welding techniques (hot-air welding or PVC adhesive for field repairs) and test weld strength before final assembly.

- Avoid sharp edges and ensure adequate edge protection or binding to prevent abrasion and premature failure.

- For printed banners, use appropriate inks (solvent, eco-solvent, UV, or latex) and post-cure printing where required to avoid ink migration.

- For pond and pool applications, confirm chemical compatibility (chlorine, salts) with DERFLEX technical team.

- Follow manufacturer guidance for cleaning: mild detergent, soft brush, and rinse with clean water; avoid harsh solvents and petroleum-based cleaners.

Sold To — Export Markets & Typical Customers

DERFLEX supplies vinyl tarpaulin fabric to distributors, sign printers, tent manufacturers, transportation companies and government procurement agencies worldwide. Popular export markets include:

- North America (USA, Canada)

- Europe (UK, Germany, France, Netherlands, Scandinavia)

- Australia & New Zealand

- Middle East & GCC

- Africa (selected distributors)

- Latin America (Brazil, Chile, Mexico)

FAQs — Common Questions (rich results-ready)

Q1: What is the difference between PVC tarpaulin and canvas?

A: PVC tarpaulin is a polymer-coated synthetic fabric providing superior waterproofing and UV resistance. Traditional canvas is cotton-based and requires treatment to be water resistant; it is not as durable for prolonged outdoor exposure.

Q2: Can your vinyl tarpaulin fabric be printed?

A: Yes. DERFLEX materials are optimized for wide-format printing using solvent, eco-solvent, latex and UV technologies. We provide printable finishes and pre-treatment guidance to ensure excellent ink adhesion and colour vibrancy.

Q3: Do you offer fire-retardant grades?

A: Yes. Fire-retardant (FR) options are available and can be certified to regional standards (EN, GB, NFPA) depending on the project requirements.

Q4: How should I repair a torn tarpaulin in the field?

A: Small tears can be repaired using PVC repair tape or patches with appropriate adhesive. For structural seams, hot-air welding or professional re-welding is recommended to restore full mechanical strength.

Q5: What lead times can I expect for large orders?

A: Typical lead time is 15–35 days depending on quantity, coating options and finishing. Expedited production may be available for urgent projects; please contact DERFLEX sales for current schedules.