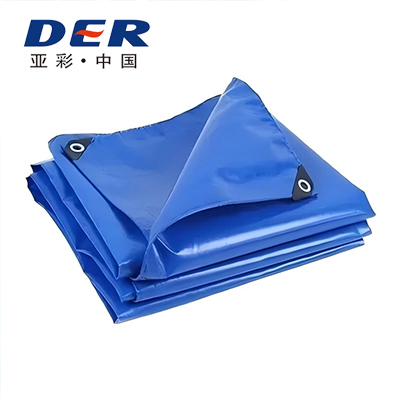

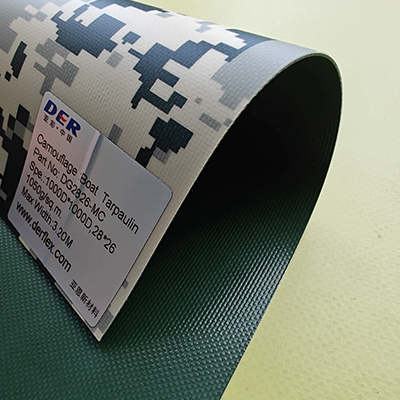

- tarp

- Frontlit banner

- PVC flex backlit

- Blockout banner

- PVC vinyl sticker

- Tarpaulin

- PVC mesh banner

- PVC preformated vinyl

- Reflective vinyl

- Dye Sublimation fabric

- PVC Stretch Ceiling Film

- Super clear pvc film

- PVC coated fabrics

- TPO coated fabric

- TPU coated fabric

- Inkjet media

- Textile banner

- Mesh banners

- New Products

- customized PVC tarps products

- PVC Foam Board Sheet

- Profile download

- Services Hotline

+86-021-54361792 / 54361798 - Email

sales@derflex.com

|

|

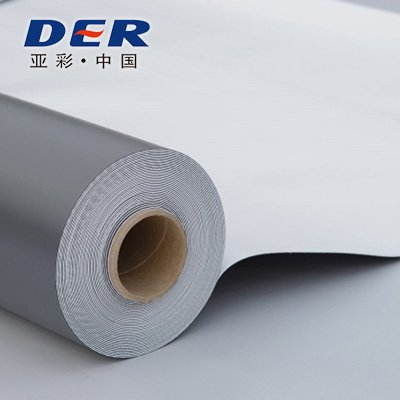

Waterproof Membrane

DERFLEX is a leading waterproof membrane manufacturer specializing in PVC, TPO, TPU, EPDM, HDPE waterproof sheets for roofing, tunnels, foundations, agriculture, and industrial engineering. Factory direct supply, high durability, UV resistant, long service life.

|

|

||||||||||||||||||||||||

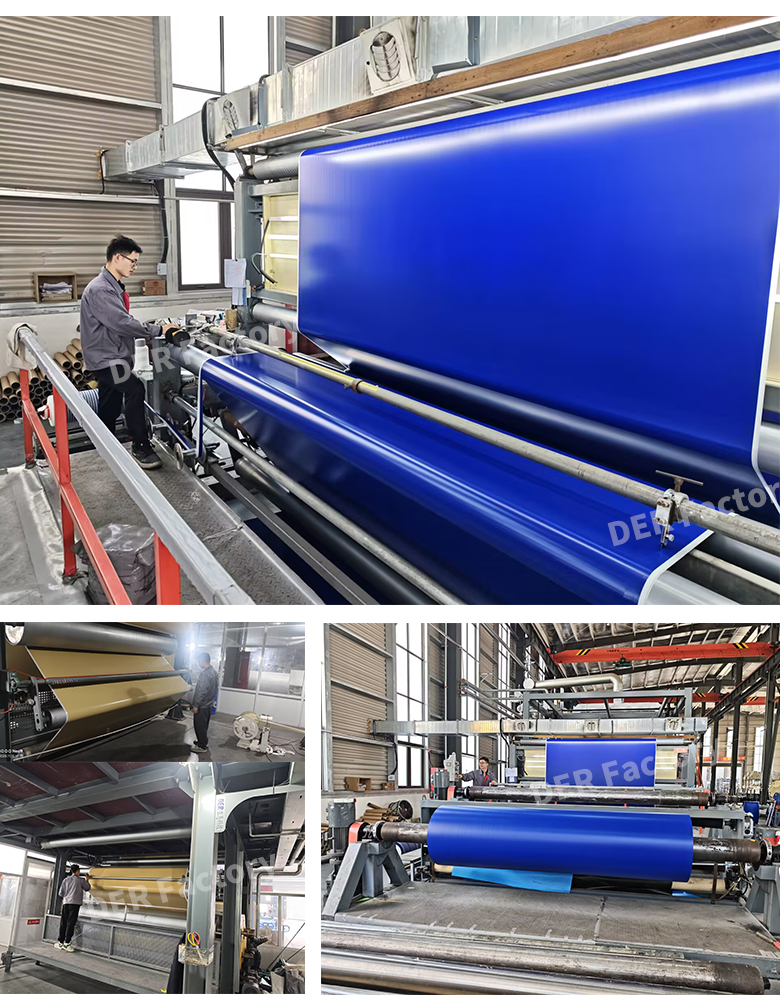

Waterproof Membrane Manufacturer – PVC, TPO, EPDM, HDPE Waterproofing SolutionsDERFLEX is a professional waterproof membrane manufacturer and supplier with more than 20 years of experience in industrial polymer materials, construction waterproofing systems, geotechnical membranes, and roofing materials. Our waterproof membranes are engineered for long-term durability, UV resistance, chemical stability, and excellent water barrier performance. Available materials include PVC, TPO, TPU, EPDM, EVA, LDPE/HDPE geomembrane and composite waterproof membranes, which are widely used in: commercial roofing, building foundations, tunnels, landfills, water retention structures, agriculture, aquaculture, mining, and environmental engineering projects. What Is a Waterproof Membrane?A waterproof membrane is a functional polymer sheet designed to prevent water penetration, moisture infiltration, chemical corrosion, and structural leakage in construction and industrial applications. DERFLEX waterproof membranes offer: Our waterproof membranes comply with international standards including ISO, ASTM, CE, making them suitable for architectural, municipal, geotechnical, and industrial waterproofing systems. Types of Waterproof Membranes Available from DERFLEX1. PVC Waterproof MembranePVC waterproofing membrane is highly durable with excellent tensile strength, weldability, and chemical resistance. Ideal for: 2. TPO Waterproof MembraneThermoplastic Polyolefin membranes are environmentally friendly, UV-stable, and widely used in roofing. 3. EPDM Waterproof SheetEPDM rubber membranes provide exceptional weatherability and elastic performance, ideal for extreme climate conditions. 4. HDPE GeomembraneHDPE waterproof liners are used in large engineering projects, offering outstanding chemical resistance and impermeability. 5. TPU Waterproof FilmTPU membranes deliver superior elasticity, abrasion resistance, and low-temperature flexibility. 6. Composite Waterproof MembranesMulti-layer membranes combining geotextile + polymer film for geotechnical and municipal applications. Main Features of DERFLEX Waterproof Membranes1. Superior Waterproof PerformanceDERFLEX membranes provide complete protection against water leakage, hydrostatic pressure, and moisture vapor. 2. UV & Weather ResistanceOur products are suitable for long-term outdoor exposure with up to **15–25 years** service life. 3. Excellent FlexibilityEven in cold environments, membranes maintain flexibility to accommodate structural movement. 4. Strong Puncture & Tear ResistanceIdeal for construction, industrial and environmental engineering projects. 5. Chemical & Microbial ResistanceResistant to acids, alkalis, oils, and microorganisms, ideal for landfills, wastewater plants and chemical facilities. 6. Environmentally Friendly OptionsTPO, EPDM and HDPE membranes are recyclable and comply with green building requirements. Applications of Waterproof MembranesBuilding & ConstructionTunnels & Underground StructuresEnvironmental EngineeringAgricultural & Aquaculture ProjectsIndustrial WaterproofingTechnical Specifications

Why Choose DERFLEX as Your Waterproof Membrane Supplier?1. 20+ Years of Manufacturing ExperienceDERFLEX has supplied waterproofing materials to more than 80 countries, supporting global construction projects. 2. Full Range of Materials3. Strict Quality Control4. Custom Production Available5. Global Project Support

DERFLEX provides technical support, sample testing, and complete documentation for engineering bidding.

Installation & Usage Guide1. Surface PreparationEnsure the substrate is clean, dry, smooth and free of sharp objects. 2. Welding Methods3. Overlap RequirementsOverlap width should be **≥ 50–80 mm** to ensure waterproofing integrity. 4. StorageFAQ – Waterproof Membrane1. What is the best waterproof membrane for roofing?PVC and TPO membranes are the most widely used for commercial and industrial roofing. 2. Can waterproof membranes be used underground?Yes, DERFLEX membranes are suitable for basements, tunnels, and foundation waterproofing. 3. What is the lifespan of a waterproof membrane?Depending on material, the lifespan ranges from **10 to 25+ years**. 4. Do you support OEM production?Yes, DERFLEX provides OEM/ODM waterproof membrane manufacturing and custom printing. 5. Can you provide samples for testing?Yes, sample rolls and testing data sheets are available. |

||||||||||||||||||||||||