Why Choose Derflex Agricultural Tarps?

Farmers and agricultural professionals choose Derflex because we design tarpaulins with real-world agricultural conditions in mind. We combine modern materials science with on-farm feedback to produce covers that resist UV breakdown, tear propagation and seepage — critical factors when protecting silage piles, haystacks, water containment, or seedlings.

Key benefits

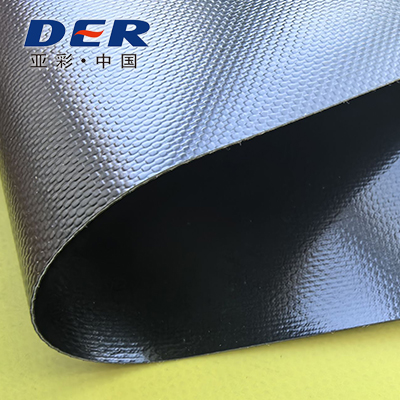

- Proven durability: High tensile polyester base fabrics and multi-layer PVC coatings deliver excellent tear and puncture resistance under heavy loads and uneven surfaces.

- UV and weather resistance: Special UV stabilizers and fade-resistant pigments reduce material degradation and extend service life under intense sunlight.

- Waterproof & airtight: Precision lamination and welded hems ensure water-tight performance — essential for silage preservation and pond liners.

- Customizable: Sizes, colors, weights, and fittings (eyelets, D-rings, steel grommets) are tailored to your application and local climate.

- Cost-effective lifecycle: Lower replacement frequency and reduced product loss (e.g., feed spoilage) lower total cost of ownership.

Common Agricultural Applications

Derflex agricultural tarps are sold into multiple application categories. Below are typical uses with recommended product recommendations and why specific features matter.

1. Silage Covers

Silage preservation requires low-oxygen, water-tight protection to keep fermenting material dry and anaerobic. Our silage tarps are typically heavy-duty (600–900 gsm), with welded seams and optional gas-barrier coatings. For long-term silage storage we recommend a dual-layer approach: a black/white silage tarp (black side to reduce light transmission, white side to reflect heat) combined with sandbags or edge ballast for sealing.

2. Hay & Straw Covers

Hay needs breathable protection to avoid moisture build-up yet resist rain and UV exposure. For hay stacks we recommend medium-weight PVC-coated fabrics (400–650 gsm) with reinforced corners and UV-resistant coating. Perforated or breathable variants are available for ventilated storage to reduce condensation risk.

3. Pond Liners & Water Containment

Pond liners must be impermeable and resist aquatic chemicals and abrasion. Derflex pond tarps use thick PVC or reinforced PE laminates (500–900 gsm) with welded seams and optional chemical-resistant additives. We perform QA testing for hydrostatic resistance and provide guidance for sub-base preparation to minimize puncture risks.

4. Greenhouse & Shade Tarps

Greenhouses and shade structures require materials that balance light transmission, UV protection, and thermal performance. Derflex greenhouse tarps are available in translucent PVC and specialized woven films with anti-drip and anti-condensation treatments. Custom perforation patterns and light-diffusion surface treatments are available on request.

5. Compost & Fertilizer Covers

Compost piles release heat and moisture: our compost tarps resist microbial degradation, are heat-stable and come with optional anti-microbial coatings for longer life. For fertilizer storage, we provide options with chemical resistance and low dust adherence.

Materials & Construction Details (Technical)

This section provides technical buyers and procurement teams with material specifications, test methods, and inspection criteria aligning with industry expectations.

Base Fabric

We use industry-standard high-tenacity polyester woven base cloths with counts and tensile properties matched to application. Typical base fabrics include 1000D to 2000D polyester, coated with PVC or laminated with PE films for additional property control.

Coating & Lamination

Our PVC coatings are formulated for outdoor stability — incorporating UV absorbers, heat stabilizers, slip agents and anti-fungal additives. Coating thickness is controlled to achieve target GSM and testable properties (tensile strength, elongation, adhesion, hydrostatic resistance).

Seams & Reinforcements

Seams are available in both hot-weld and high-frequency welded configurations depending on material. Reinforcements include double-fold hems, cross-stitching for added shear strength, corner patches and webbing for load-bearing points.

Fittings & Hardware

We provide brass or stainless-steel grommets (eyelets), D-rings, rope sleeves and welded-in aluminium channels for specific heavy-duty installations. Hardware selection is guided by corrosion risk (coastal, marine environments) and expected tension loads.

Performance & Testing

- Tensile strength (warp/weft) — tested to ISO 13934 / ASTM D5034

- Tear resistance — tested to EN ISO 4674 / ASTM D2261

- Hydrostatic head (waterproof rating) — tested to EN 20811 / ASTM D751

- UV resistance (accelerated weathering) — ISO 4892, QUV cycles

- Flame retardant options — tested to EN 13501-1 / NFPA 701 where required

Product Range & Model Recommendations

Below is a selection of typical SKUs and recommended use-cases. We manufacture to custom dimensions, but common stock items ease ordering and logistics.

Typical Agricultural Tarps — representative SKUs

| Model |

GSM |

Fabric |

Recommended Use |

Notes |

| DF-AG-600 |

600 gsm |

PVC-coated polyester |

Silage cover, long-term storage |

Welded seams, black/white option, stainless grommets |

| DF-AG-450 |

450 gsm |

PE laminated woven |

Hay & straw packing, temporary covers |

Lightweight, breathable alternative available |

| DF-AG-800 |

800 gsm |

Reinforced PVC high-tenacity |

Pond liner, heavy water containment |

Thick laminate with chemical resistance |

| DF-AG-350-SH |

350 gsm |

Translucent PVC |

Greenhouse temporary cover, shade |

Anti-condensation finish available |

| DF-AG-500-C |

500 gsm |

Anti-microbial PVC |

Compost and fertilizer covers |

Heat-stable, fungus-resistant finish |

Ordering, Customization & Lead Times

We provide both standard sizes and full custom fabrication. Typical customization options include:

- Custom dimensions (up to roll width limits)

- Color and UV pigment choices for heat reflection or low-visibility

- Printed brand logos and safety markings using fade-resistant inks

- Special coatings (fire-retardant, anti-microbial, anti-static)

- Fittings: grommets, D-rings, webbing reinforcement, ballast sleeves

Lead times: For stock items our export lead time is typically 2–6 weeks depending on order quantity and destination port. For custom runs lead time depends on tooling and quantity — we’ll provide firm lead time in written Pro Forma Invoice. Note: lead times can change seasonally; always check with our sales team at info@derflex.com.

Packaging, Shipping & Logistics

We package agricultural tarps to minimize damage in transit. Options include:

- Rolled & shrink-wrapped with protective end caps

- Folded & carton-packed for smaller sizes

- Custom palletization for large orders

We ship worldwide via sea freight (FCL/LCL), airfreight and express for samples. Our logistics team can advise on optimal INCOTERMS, HS codes and required export documentation.

Quality Assurance & Certifications

Derflex adheres to strict quality control and manufacturing best practices. Our facilities are ISO certified and we maintain batch-level traceability for core materials. Certifications and testing available on request include:

- ISO 9001 Quality Management

- Product test reports for tensile, tear and hydrostatic resistance

- Third-party verification for flame retardant claims (if specified)

- REACH & RoHS guidance for chemical compliance where applicable

Environmental & Sustainability Practice

Derflex actively works to improve the environmental profile of our products and operations. Agricultural tarps manufactured with PVC are energy-intensive to produce but deliver long service life that reduces frequent replacements. We also offer PE laminated alternatives with lower-volatility additives and can provide guidance on recycling streams where available.

End-of-life options

- Take-back programs for large, recurring orders — inquire with sales.

- Advice on landfill diversion and mechanical recycling where local facilities accept coated fabrics.

Installation & Best Practices

Proper handling extends tarp life and maximizes protection. Below are recommended practices for common applications.

Silage Cover Installation

- Prepare the pile with smooth slopes and remove sharp debris before covering.

- Lay primary silage tarp (black side down / white side up option) and smooth out wrinkles to reduce puncture points.

- Secure edges using sandbags, ballast tires or dedicated ballast tubes — maintain constant edge pressure.

- Use overlap and seaming tape between covers for very large piles to maintain airtightness.

Pond Liner Installation Tips

- Prepare and compact the sub-base to remove stones and roots.

- Install geotextile underlayment to reduce puncture risk.

- Weld seams using a qualified technician and test for leaks before filling.

Case Studies & Customer Stories

We work with farms and agricultural integrators globally. Examples include silage protection programs in Northern Europe, pond lining projects for fish farms in Southeast Asia, and custom greenhouse covers for horticultural clusters in South America. We are happy to share anonymized technical case studies and test data upon request for procurement and engineering reviews.

Frequently Asked Questions (FAQ)

Q: Which tarp weight should I choose for silage?

A: For silage we recommend 600–900 gsm heavy-duty PVC tarps. If you have frequent handling or extreme weather, choose 800–900 gsm with reinforced hems and stainless grommets.

Q: Are your tarps UV resistant?

A: Yes — all outdoor-grade agricultural tarps include UV stabilizers and fade-resistant pigments. For extreme high-UV environments we suggest higher pigment load and periodic inspection.

Q: Can you print our company logo on the tarp?

A: Yes — we offer UV-stable screen printing and digital printing for logos, safety markings and instructions. Please provide vector artwork and requested placement.

Q: Do you supply installation hardware?

A: We can supply grommets, rope sleeves, D-rings and ballast tubes as part of a finished product. For complex installations we can recommend local installers in many regions.

Q: What warranty comes with Derflex agricultural tarps?

A: Warranty depends on product type and application. Standard limited warranty covers manufacturing defects; extended warranties are available for certain uses with documented maintenance plans. Contact sales for warranty details tailored to your order.

Contact & Sales Support

For quotations, technical drawings or sample requests please contact our agricultural team:

Email: info@derflex.com

State your required size, quantity, intended use, and destination port — this helps us generate accurate pricing and lead times quickly.

Product Schema & Google Rich Results

The following JSON-LD markup helps Google and other search engines understand product details for rich results. (The markup below includes representative fields — update SKU, GTIN, price and availability per your production data when publishing.)

Compliance & Export Notes

Export customers should consult their local import regulations for coated fabric goods. We will provide HS codes and material test reports to facilitate customs clearance. For certain food/feed contact applications additional documentation and certification may be required — discuss specifics with our compliance team.

Comparison: PVC vs. PE Agricultural Tarps

Understanding material differences helps choose the right product. Below is a short comparison to assist procurement and farm managers.

| Property |

PVC Coated Polyester |

PE Laminated Woven |

| Tear & Tensile |

Excellent — high strength, excellent tear resistance |

Good — lower tensile strength but usually lighter weight |

| Waterproof |

Fully waterproof — welded seams |

Waterproof but seam methods differ |

| UV lifespan |

Longer with proper stabilizers |

Good but may degrade faster in extreme sun |

| Cost |

Higher, due to coatings and processing |

Lower — cost-effective for temporary covers |

| Recyclability |

Challenging, depends on local facilities |

Sometimes easier to recycle |

Legal & Safety Notices

Derflex tarps are designed for their intended agricultural purposes. Improper installation or handling may cause injury or product failure. Always follow the installation guide and use appropriate PPE when handling heavy tarps. For flame-retardant applications, request certified fire-retardant products and documentation.

Get a Sample

We provide small samples for material evaluation. A nominal sample charge may apply. To request, email samples@derflex.com with your shipping address and the SKU or material type you wish to review.

Buy Direct From Factory or Through Distributors

Derflex sells factory-direct to bulk customers and works with a network of authorized distributors for retail and regional support. If you prefer local pickup or faster support, ask our sales team for authorized distributor contacts in your country.

Concluding Notes

Derflex agricultural tarps blend field-proven engineering and flexible manufacturing — supplying contractors, farms and integrators with high-performance covers designed to reduce spoilage, contain water, and extend asset life. Whether you need a standard silage cover or a highly customized pond liner, our team can assist from specification to delivery.