What Is the Best Material for Dry Bags?

Dry bags protect personal belongings from water during outdoor activities such as kayaking, rafting, fishing, camping, and marine use. To achieve perfect waterproof performance, the choice of material is the most critical factor. Based on long-term manufacturing and global OEM experience, DERFLEX identifies the three best waterproof materials for dry bags:

- PVC tarpaulin – most durable and widely used

- TPU (Thermoplastic Polyurethane) fabric – premium eco-friendly material

- Nylon/Polyester coated fabrics – lightweight and cost-effective

Each material offers different advantages depending on the application, brand positioning, and durability requirements. As a professional waterproof material manufacturer with 20+ years of experience, DERFLEX provides customized solutions for global dry bag brands.

Top Waterproof Materials for Dry Bags

1. PVC Tarpaulin (Most Popular & Cost-Effective)

PVC tarpaulin is the industry-standard material for dry bags thanks to its balance of durability, waterproofing, and manufacturing ease. It features a polyester base cloth coated with PVC resin, offering high mechanical strength.

- 100% waterproof

- High abrasion resistance

- Excellent durability for marine use

- Budget-friendly for mass production

- Available in multiple thicknesses (0.35mm–1.0mm)

2. TPU Fabric (Premium & Eco-Friendly)

TPU is a high-performance polymer known for its flexibility, transparency options, eco-friendly formulation, and superior cold resistance. TPU dry bags are lightweight and preferred by premium outdoor brands.

- Lightweight yet strong

- Odorless and eco-friendly (non-toxic)

- Superior cold resistance (-50°C)

- Higher elasticity compared to PVC

- Perfect for roll-top waterproof bags

3. Nylon/Polyester Coated Fabrics

Typically coated with PU or TPU, these materials offer a lightweight structure but require careful seam sealing. They are popular for backpack-style dry bags and lightweight adventure gear.

- Very lightweight

- Ideal for long-distance hiking

- Good tear strength

- More budget-friendly than TPU

Technical Specifications of Dry Bag Materials

| Material Type | Common Weights | Thickness | Waterproof Rating | Strength Level | Key Applications |

|---|---|---|---|---|---|

| PVC Tarpaulin | 300–900gsm | 0.35–1.0mm | 100% waterproof | High abrasion strength | Dry bags, marine bags, waterproof backpacks |

| TPU Fabric | 250–600gsm | 0.3–0.8mm | 100% waterproof | High elasticity & flexibility | Premium lightweight dry bags |

| Nylon/Polyester Coated | 100–350gsm | 0.15–0.4mm | Water-resistant to waterproof (depending on coating) | Moderate | Hiking dry sacks, ultralight waterproof bags |

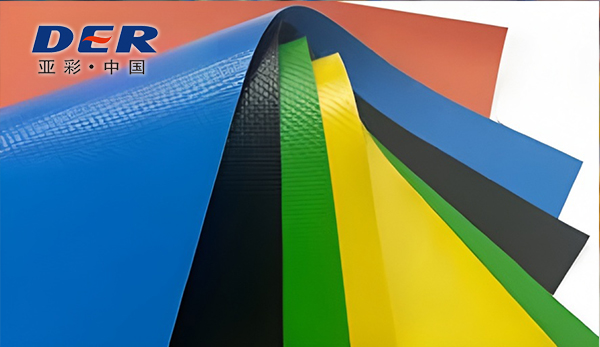

Available Colors for Dry Bag Materials

DERFLEX offers a full range of standard and custom colors:

- Black / Navy Blue / Sky Blue

- Red / Bright Red

- Yellow / Safety Yellow

- Green / Military Green

- Orange / High-visibility Orange

- Transparent TPU

- Camo and printed patterns

- Pantone custom colors

Applications of Dry Bag Materials

✔ Outdoor Sports

Fishing, kayaking, rafting, surfing, boating.

✔ Camping & Hiking

Protecting clothing, electronics, and gear from water.

✔ Marine & Diving Gear

Saltwater-resistant materials suitable for long-term marine use.

✔ Commercial Use

Courier bags, delivery bags, adventure backpacks.

✔ OEM Outdoor Brands

Roll-top bags, waterproof backpacks, dry sacks.

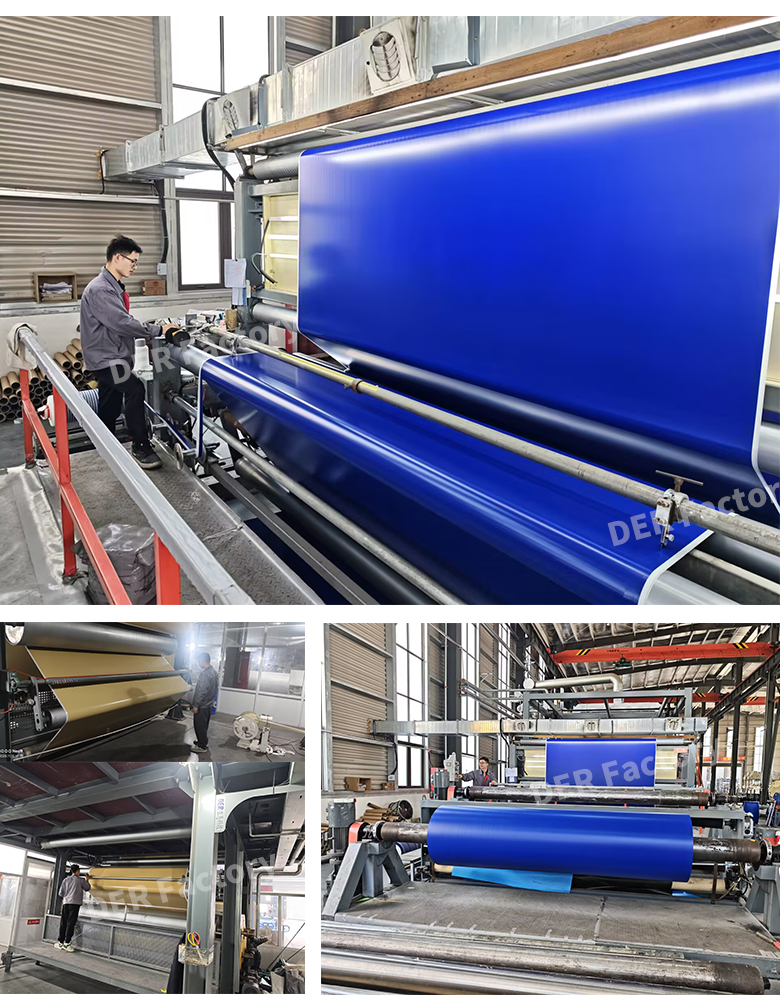

DERFLEX Company Profile

DERFLEX is a leading manufacturer of PVC tarpaulin, TPU fabric, coated textiles, and industrial waterproof materials with more than 20 years of production experience. We offer large-scale manufacturing, advanced coating equipment, strict quality control, and professional OEM customization for global outdoor brands.

With exports to over 120+ countries, DERFLEX supports outdoor equipment manufacturers, marine gear companies, and waterproof backpack brands worldwide.

Certifications

- ISO 9001 Quality Management System

- REACH Compliance

- RoHS Certification

- SGS Test Report

- UV Aging Test

- Phthalate-Free Eco PVC Certification

Why Choose DERFLEX as Your Dry Bag Material Supplier?

✔ Complete Material Solutions (PVC, TPU, Nylon)

We provide full-category waterproof materials for all dry bag types.

✔ 20+ Years Manufacturing Expertise

Stable production capacity, strong QC, reliable delivery.

✔ OEM & ODM Support

Custom thickness, colors, printing, and performance levels.

✔ Global Export Experience

Serving top outdoor brands across North America, Europe, Asia, and Oceania.

✔ Competitive Factory Prices

Direct manufacturing ensures cost efficiency and stable supply.

Processing & Installation Precautions

- Choose correct welding temperature for PVC or TPU.

- Ensure surface is clean before HF welding or hot-air welding.

- For transparent TPU, avoid overheating to prevent yellowing.

- Store materials in cool, dry, ventilated environments.

- Use high-quality seam tape for coated nylon materials.

Countries We Supply Dry Bag Materials To

DERFLEX exports waterproof materials to more than 120+ countries:

- USA, Canada, Mexico

- UK, Germany, Netherlands, France, Spain

- Australia, New Zealand

- Japan, Korea, Singapore

- Brazil, Chile, Peru

- South Africa, Egypt, UAE

Frequently Asked Questions

1. What is the strongest material for dry bags?

PVC tarpaulin is the strongest in terms of abrasion resistance and durability.

2. Which material is best for premium dry bags?

TPU fabric is ideal due to lightweight design and superior cold resistance.

3. Can dry bag materials be custom printed?

Yes. DERFLEX provides digital printing, camouflage patterns, logo printing, and Pantone matching.

4. What thickness should I choose?

Standard recommendations:

- Light dry sacks: 0.3–0.4mm TPU

- Outdoor dry bags: 500–600D PVC

- Heavy-duty marine: 840D–1000D PVC

5. Do you offer OEM dry bag manufacturing?

Yes. DERFLEX cooperates with professional dry bag factories for OEM services.