Dry Bag Material Factory - Premium Waterproof Fabric Manufacturer | DERFLEX

DERFLEX is a leading dry bag material factory specializing in the manufacturing of high-quality waterproof fabrics for outdoor dry bags, dry sacks, kayaking bags, backpack liners, and ocean-grade protective bags. With more than 20 years of industrial textile expertise, DERFLEX supplies durable, waterproof, and heat-weldable materials to top global outdoor brands.

We produce a wide range of PVC dry bag material, TPU dry bag fabric, welded dry sack material, waterproof PVC coated fabric, and eco-friendly laminated materials, ensuring maximum waterproof performance from IPX6 up to IPX8 for professional outdoor adventures.

Product Introduction – High-Performance Dry Bag Material

DERFLEX dry bag materials are designed for long-term outdoor use, featuring excellent waterproofing, durability, and flexibility. Whether for kayaking, rafting, fishing, camping, or military waterproof storage products, our fabrics guarantee reliable performance in extreme environments.

Main Material Options

- PVC Tarpaulin for Dry Bags – cost-effective, strong, easy to weld

- TPU Laminated Fabric – eco-friendly, lightweight, superior cold resistance

- Ripstop Dry Bag Fabric – tear-resistant with PU/TPU coating

- High-Frequency Weldable Films – seamless waterproof construction

Material Advantages

- 100% waterproof with IPX6–IPX8 rating

- High tensile strength and tear resistance

- Heat-weldable for factory sealing

- UV-resistant and anti-aging

- Low-temperature flexibility for snow and ice conditions

- Chemical and abrasion resistant

Product Specifications

| Item | Specification |

|---|---|

| Material Options | PVC Coated Fabric / TPU Laminated Fabric / Oxford PU |

| Weight | 350gsm – 1000gsm |

| Thickness | 0.25mm – 1.2mm |

| Width | 1.0m – 2.5m |

| Waterproof Rating | IPX6–IPX8 |

| UV Resistance | 500–2000 hours |

| Available Surface | Glossy / Matte / Embossed / Ripstop |

| Temperature Range | -30°C to 70°C |

| Color | Customizable |

| Welding Method | HF Welding, Hot Air Welding, Overlap Sealing |

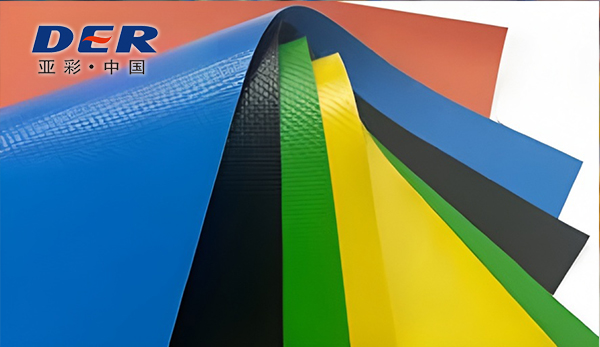

Product Colors

DERFLEX dry bag material is available in a wide color selection:

- Black

- Yellow

- Red

- Blue

- Orange

- Army Green

- Transparent TPU

- Custom Pantone colors

Logo printing and pattern customization are available for OEM orders.

Application Fields

- Outdoor dry bags (1L–90L)

- Kayak & rafting dry sacks

- Floating waterproof bags

- Backpack liners & compression bags

- Military waterproof pouches

- Fishing equipment bags

- Camping & hiking waterproof gear

- Mobile phone waterproof cases

DERFLEX Company Profile

DERFLEX is a professional industrial fabric manufacturer established in 2001. With large-scale PVC coating lines, TPU lamination production, and advanced testing labs, we have become one of China’s most trusted dry bag material factories.

- 20+ years manufacturing experience

- 80+ exporting countries

- ISO9001 certified production

- R&D capability for custom outdoor materials

- Over 5 million meters annual output

Certifications

- ISO9001 Quality Management System

- ROHS / REACH Compliance

- SGS Waterproof & Durability Testing

- UV Resistance & Aging Laboratory Reports

Why Choose Us

- China’s top dry bag material factory with stable supply

- Advanced coating and lamination lines

- Strict QC system for consistent quality

- Customized fabric width, color, thickness & surface

- OEM & ODM support for outdoor brands

- Fast delivery with reinforced packaging

Installation Precautions (For Manufacturers)

- Use HF welding or hot-air welding for best sealing results

- Store fabric away from UV exposure before processing

- Keep cutting and welding surfaces clean

- Pre-test weld strength before mass production

- Ensure fabric edges are properly overlapped during sealing

Sold to Countries

DERFLEX dry bag material is supplied to over 80+ countries:

- United States

- Canada

- Germany

- United Kingdom

- Australia

- Japan

- South Korea

- Philippines

- Brazil

- South Africa

FAQs

1. Is DERFLEX really a dry bag material factory?

Yes, DERFLEX operates PVC coating and TPU lamination lines, producing millions of meters of dry bag fabric annually.

2. What is the best material for high-end dry bags?

TPU laminated fabric is the premium option because it's lightweight, eco-friendly, odor-free, and highly flexible.

3. Can you provide OEM logo printing?

Yes, we offer screen printing, digital printing, and color customization for branding needs.

4. What is the usual MOQ?

Standard MOQ is 1000 meters, but trial orders are accepted.

5. How long is production time?

Typical production time is 15–25 days depending on customization.