Inflatable Tent Manufacturer & Industrial Inflatable Shelter Supplier

Inflatable tents, also known as inflatable shelters or air tents, are rapidly deployable structures designed for temporary or semi-permanent use in demanding environments. Compared with traditional frame tents, inflatable tents offer significant advantages in installation speed, mobility, and structural stability.

As a global manufacturer of industrial PVC materials and inflatable structures, :contentReference[oaicite:0]{index=0} supplies high-performance inflatable tents engineered for emergency response, military logistics, medical facilities, industrial operations, and commercial events.

What Is an Inflatable Tent?

An inflatable tent is a structural enclosure supported by inflatable air beams instead of traditional metal or fiberglass frames. Once inflated using an electric or manual pump, the air beams create a rigid, load-bearing structure capable of withstanding wind, rain, and temperature fluctuations.

Modern inflatable tents are manufactured using reinforced PVC fabrics or coated textile membranes, ensuring excellent airtightness, tear resistance, and weather durability. These characteristics make inflatable tents suitable for both short-term emergency deployment and longer-term operational use.

Core Advantages of Inflatable Tent Structures

- Rapid deployment with minimal manpower

- No rigid metal framework required

- High wind resistance due to flexible air-beam design

- Compact packing size for transportation and storage

- Excellent waterproof and airtight performance

- Adaptable to multiple climates and terrains

Inflatable Tent Materials & Construction

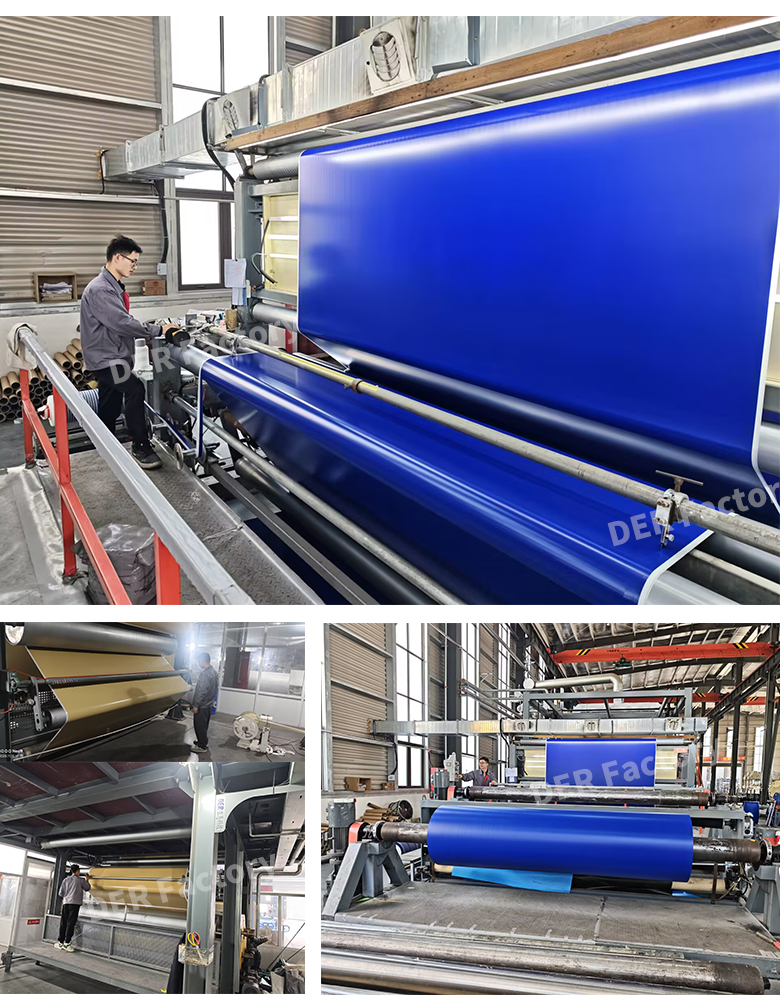

The performance of an inflatable tent is largely determined by the quality of its base materials. DERFLEX inflatable tents are produced using high-strength PVC-coated fabrics developed specifically for inflatable applications.

PVC-Coated Fabric Structure

- High-tenacity polyester base fabric

- PVC coating with UV inhibitors

- Optional flame-retardant formulation

- Anti-mildew and anti-hydrolysis treatment

Air Beam & Seam Technology

Air beams are manufactured using high-frequency welding or hot-air welding technology, ensuring airtight seams capable of maintaining internal pressure over extended periods. Reinforced stress points are applied at load-bearing intersections to improve structural safety.

Technical Specifications

| Parameter | Specification Range |

|---|---|

| Base Fabric | High-tenacity polyester |

| Coating | PVC / TPU optional |

| Fabric Weight | 650 – 1100 g/m² |

| Waterproof Rating | ≥ 10,000 mm |

| Operating Temperature | -30°C to +70°C |

| Fire Retardancy | Optional (B1 / NFPA 701) |

Applications of Inflatable Tents

Emergency & Disaster Relief

Inflatable tents are widely used in disaster relief scenarios due to their fast setup and portability. They serve as temporary shelters, command centers, and storage units in earthquakes, floods, and humanitarian missions.

Medical & Healthcare Facilities

Inflatable medical tents are used as mobile hospitals, triage centers, isolation wards, and vaccination stations. Their airtight structure allows controlled ventilation and zoning.

Military & Defense Operations

For military logistics, inflatable shelters provide field accommodation, equipment storage, and command posts with reduced transportation volume and fast deployment.

Industrial & Commercial Use

Inflatable tents are also applied in industrial maintenance, mining operations, outdoor exhibitions, sports events, and temporary warehouses.

Types of Inflatable Tents Supplied

- Emergency inflatable tents

- Medical inflatable shelters

- Military inflatable tents

- Inflatable warehouse tents

- Inflatable event tents

- Custom inflatable structures

Customization & OEM Capabilities

DERFLEX offers full OEM and ODM services for inflatable tents. Customization options include:

- Custom dimensions and layouts

- Color and branding options

- Flame-retardant and cold-resistant materials

- Integrated doors, windows, and ventilation systems

- Modular connection systems

Quality Control & Performance Testing

- Airtightness pressure testing

- Seam strength and peel resistance testing

- Fabric tensile and tear strength inspection

- Weather resistance validation

- Long-term inflation stability testing

Why Choose DERFLEX as Your Inflatable Tent Supplier?

- Extensive experience in PVC-coated fabric manufacturing

- Integrated material + finished structure production

- Stable quality for large-scale international supply

- Professional technical and engineering support

- Long-term cooperation focus

Frequently Asked Questions

How long does it take to set up an inflatable tent?

Most inflatable tents can be fully deployed within 5–15 minutes, depending on size and configuration.

Do inflatable tents require continuous air supply?

No. Once inflated and sealed, high-quality inflatable tents maintain pressure without continuous pumping.

Are inflatable tents suitable for extreme weather?

Yes. Industrial inflatable tents are designed to withstand wind, rain, and temperature variations when properly anchored.

Can inflatable tents be customized?

Yes. DERFLEX provides comprehensive customization and OEM services.