Laminated Flex Banner Material Manufacturer & Supplier

Laminated flex is one of the most widely used PVC-based advertising materials in the global signage and large-format printing industry. Designed for cost efficiency, stable printability, and reliable outdoor performance, laminated flex banners are extensively applied in commercial advertising, promotional displays, and temporary outdoor signage.

As a professional laminated flex manufacturer and exporter supplies a full range of laminated flex banner materials engineered for consistent quality, smooth printing surfaces, and dependable durability across diverse climates and application environments.

What Is Laminated Flex?

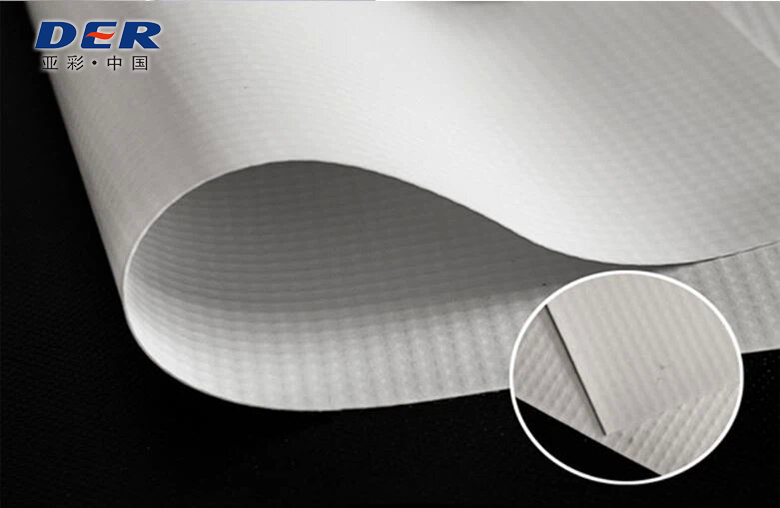

Laminated flex is a PVC composite banner material produced by laminating PVC films onto a high-strength polyester scrim using heat and pressure. Unlike knife-coated or calendared materials, laminated flex focuses on cost-effective mass production while maintaining sufficient mechanical strength and print stability.

The lamination process creates a balanced structure in which the PVC film provides surface smoothness and weather resistance, while the internal polyester fabric delivers tensile strength and dimensional stability. This structure makes laminated flex an ideal choice for large-volume advertising applications.

Key Features of Laminated Flex Banner

- Cost-effective solution for large-format advertising

- Stable and smooth surface for digital printing

- Good tensile strength and tear resistance

- Suitable for both indoor and short-to-medium-term outdoor use

- Compatible with solvent, eco-solvent, UV and latex inks

- Easy cutting, welding and finishing

Laminated Flex Manufacturing Technology

DERFLEX utilizes advanced lamination production lines that precisely control temperature, pressure, and bonding uniformity. Each laminated flex roll is produced with strict thickness consistency and surface flatness to ensure reliable printing performance.

Compared to low-end laminated materials, DERFLEX laminated flex banners demonstrate improved PVC adhesion, reduced curling, and enhanced durability during installation and exposure.

Technical Specifications

| Parameter | Specification Range |

|---|---|

| Base Fabric | Polyester scrim (200D – 1000D) |

| Weight | 280 – 510 g/m² |

| Thickness | 0.28 – 0.45 mm |

| Width | Up to 5.1 m |

| Surface Finish | Glossy / Matte |

| Ink Compatibility | Solvent, Eco-solvent, UV, Latex |

Main Applications of Laminated Flex

Outdoor Advertising Banners

Laminated flex banners are extensively used for billboards, building wraps, fence banners, and roadside advertising where cost efficiency and visual impact are key priorities.

Indoor Promotional Displays

For retail promotions, exhibitions, and point-of-sale displays, laminated flex provides an economical solution with excellent print clarity and easy handling.

Event & Temporary Signage

Due to its flexibility and affordability, laminated flex is widely chosen for temporary events, seasonal campaigns, and short-term promotional installations.

Laminated Flex vs Coated Flex

While both laminated and coated flex materials serve the signage industry, laminated flex stands out for projects where budget control and production efficiency are critical.

- Laminated flex: economical, suitable for high-volume orders

- Coated flex: higher durability and longer outdoor lifespan

- Laminated flex: ideal for short-to-medium-term campaigns

Customization Options

- Custom weights and thicknesses

- Matte or glossy surfaces

- Frontlit and backlit laminated flex

- Customized roll widths and lengths

- Private label and OEM packaging

DERFLEX supports OEM and ODM laminated flex production, helping distributors and brand owners build consistent product lines.

Why Choose DERFLEX Laminated Flex?

- Stable quality with consistent batch control

- Export-oriented production for global markets

- Competitive pricing for large-volume supply

- Professional technical support for printers and distributors

- Long-term cooperation mindset

Quality Control & Compliance

Each laminated flex batch undergoes quality inspection covering tensile strength, surface uniformity, ink adhesion, and dimensional stability. DERFLEX follows standardized quality management systems to ensure product reliability.

Frequently Asked Questions

Is laminated flex suitable for outdoor use?

Yes. Laminated flex is suitable for short-to-medium-term outdoor advertising, especially when UV ink and proper installation are used.

What printing methods are supported?

Laminated flex is compatible with solvent, eco-solvent, UV, and latex printing technologies.

Can DERFLEX supply large roll widths?

Yes. We offer laminated flex in widths up to 5.1 meters for large-format printing applications.