- tarp

- Frontlit banner

- PVC flex backlit

- Blockout banner

- PVC vinyl sticker

- Tarpaulin

- PVC mesh banner

- PVC preformated vinyl

- Reflective vinyl

- Dye Sublimation fabric

- PVC Stretch Ceiling Film

- Super clear pvc film

- PVC coated fabrics

- TPO coated fabric

- TPU coated fabric

- Inkjet media

- Textile banner

- Mesh banners

- New Products

- customized PVC tarps products

- PVC Foam Board Sheet

- Profile download

- Services Hotline

+86-021-54361792 / 54361798 - Email

sales@derflex.com

|

|

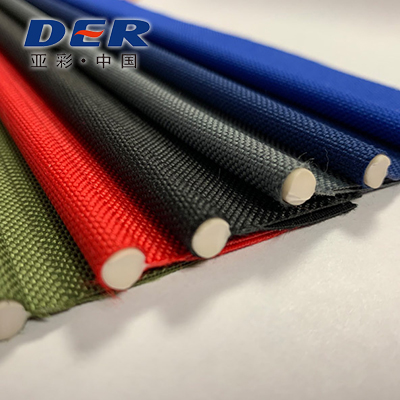

keder fabric

"DERFLEX is a leading manufacturer of high-strength PVC keder fabric for tents, banners, awnings, truck side curtains, exhibitions and industrial structures. Custom size, reinforced welding edge, UV-resistant and flame retardant. Factory price.

|

|

||||||||||||||||||||

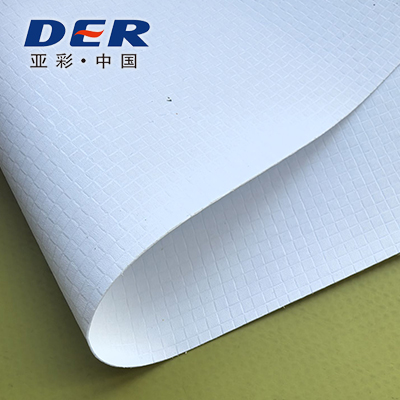

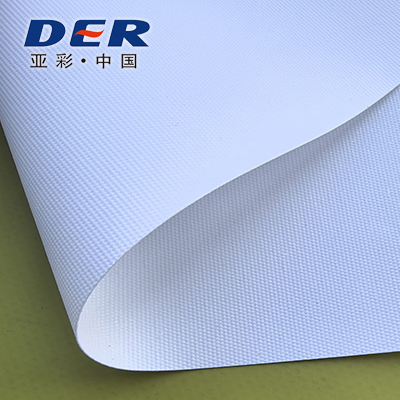

Keder Fabric – High-Strength PVC Keder Material ManufacturerDERFLEX is a professional PVC coated fabric manufacturer with over 20 years of industrial experience. Our keder fabric is specially designed for tent edges, banner connections, awning reinforcement, and industrial sliding systems. This product delivers exceptional tensile strength, dimensional stability, abrasion resistance, and reliable weldability, making it ideal for long-term outdoor structures. Whether you need regular PVC keder, reinforced keder, double-weft keder, or custom heavy-duty keder, DERFLEX can offer complete industrial-grade solutions, stable quality, and long-term supply capacity. What Is Keder Fabric?Keder fabric is a reinforced PVC coated textile used as the connection edge between fabric structures and aluminum profiles. The fabric is folded around a cord (PVC or polyester core) to create a strong sliding bead that fits into a keder rail, enabling tensioned and secure installation. DERFLEX keder material features: This makes keder fabric widely used in tents, truck tarps, industrial curtain systems, advertising frames, and modular temporary structures. Main Features of DERFLEX PVC Keder Fabric1. High Strength Polyester Base ClothWe use industrial-grade high-tenacity polyester yarn to ensure long-term tension performance. The fabric maintains shape even under extreme outdoor pulling forces. 2. Excellent WeldabilityCompatible with: The weld strength is equal to or even higher than fabric tensile strength. 3. UV and Weather ResistantPVC coating is formulated with anti-UV components, ensuring extended durability in harsh sunlight and frequent installation cycles. 4. Optional Flame Retardant Grades5. Smooth Sliding SurfaceKeder surfaces are finished with a low-friction coating to allow smooth insertion into aluminum tracks without deformation. 6. Multiple Colors & Custom WidthsStandard colors: white, grey, black. Custom colors available for branding or industrial specifications. Applications of Keder Fabric✔ Tent StructuresKeder edges ensure secure, tensioned installation for event tents, military tents, exhibition tents, and warehouse structures. ✔ Advertising & Banner FramesUsed for SEG (Silicone Edge Graphic) systems, billboard frames, outdoor advertising panels, and display systems. ✔ Awnings & Shade StructuresCreates a strong, neat edge connection with aluminum frames. ✔ Truck Side CurtainsUsed for sliding tracks in curtain-side trucks. ✔ Industrial CurtainsCommon in factories, warehouses, logistics centers, and partition systems. ✔ Container Shelter Systems✔ Marine Canvas & Boat CoversTechnical Specifications of DERFLEX Keder Fabric

Why Choose DERFLEX as Your Keder Fabric Supplier?1. 20+ Years of Manufacturing ExperienceDERFLEX has been a leading PVC coated fabric manufacturer since 2001, supplying to more than 120 countries worldwide. 2. Full In-House Production3. Strict Quality ControlTested for: 4. Custom OEM / ODM ServiceLogos, colors, sizes, friction levels, roll lengths all customizable. 5. Global Shipping & Stable SupplyExport to Europe, USA, Australia, Middle East, Africa, and South America. FAQ – Keder Fabric1. What is the difference between keder fabric and keder cord?Keder fabric is the coated textile that forms the sleeve, while keder cord is the internal PVC or polyester core inserted inside the sleeve to create a sliding bead. 2. Is keder fabric compatible with all aluminum tracks?Yes. DERFLEX keder fabric fits all standard keder rails used in tents, banners, and industrial structures. 3. Can I customize width and color?Yes. We offer complete customization for industrial projects. 4. What is the typical lifespan of PVC keder?5–8 years outdoors depending on UV exposure, material weight, and installation frequency. 5. Do you offer ready-made welded keder?Yes. We offer finished keder products with cord inserted and welding completed. Contact DERFLEX for Keder Fabric Price & SamplesDERFLEX provides full technical support, custom design, and factory-direct pricing for large and small orders. Website: https://www.derflex.com |

||||||||||||||||||||