Keder Tarpaulin Manufacturer China | High-Quality PVC Keder Fabric Supplier – DERFLEX

DERFLEX is one of the most experienced keder tarpaulin manufacturers in China, offering durable and high-performance PVC keder fabric, welded keder cloth, and flexible keder materials used extensively in tents, marquees, awnings, truck side curtains, banner systems, industrial structures and more. With over 20 years of production experience, DERFLEX supplies global tent brands with strong, stable, and UV-resistant keder materials that ensure smooth sliding, long service life, and excellent welding performance.

As a professional manufacturer, DERFLEX provides OEM/ODM customized keder tarpaulin including keder diameter, fabric thickness, PVC coating, embossing texture, and reinforcement type, ensuring compatibility with all global keder tracking systems.

What is Keder Tarpaulin?

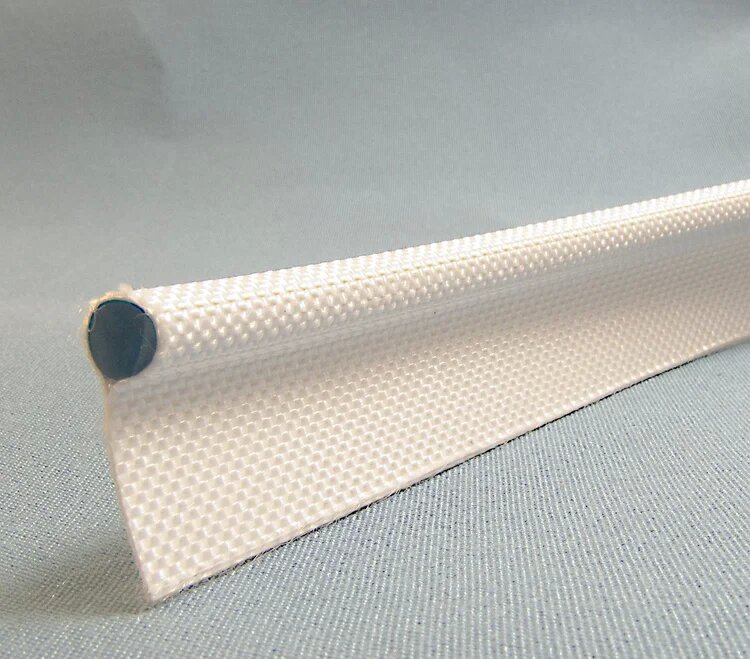

Keder tarpaulin is a reinforced PVC coated fabric used for welding with keder core (polyester or PVC cord) to form a smooth, strong edge that slides into an aluminum keder rail. It is widely used in tents, exhibition halls, truck curtain siders, inflatables, banners, awnings, and textile structures.

A typical keder consists of:

- PVC or TPU coated tarpaulin – the outer fabric layer

- Keder core – solid PVC cord or polyester rope

- High-frequency or hot-air welding to seal the core inside

DERFLEX keder tarpaulin is designed for high tensile strength, anti-tear performance, and excellent weldability. Our products ensure smooth channel movement, long outdoor lifespan, and strong load-bearing performance.

Key Features of DERFLEX Keder Tarpaulin

1. High Tensile & Tear Strength

Specially engineered for strong tension loads applied by tents and banner systems.

2. Smooth Surface for Easy Sliding

The low-friction surface ensures effortless movement inside keder tracks.

3. UV Resistant & Long Outdoor Lifespan

Available in UV-resistant, anti-aging formulations for 3–8 years of outdoor exposure.

4. Perfect Welding Compatibility

- Hot-air welding

- High-frequency welding

- Ultrasonic welding

5. Reinforcement Options

- Double-layer PVC coated fabric

- High-strength polyester base cloth

- Customized core diameters

- Anti-cold and anti-cracking options

6. Customizable Colors & Embossing

Common options: glossy, matte, fine-grain, super-smooth.

Keder Tarpaulin Technical Specifications

| Model | Base Fabric | Weight (gsm) | Thickness (mm) | Tensile Strength | Welding | Applications |

|---|---|---|---|---|---|---|

| DF-KD380 | 500D × 500D | 380gsm | 0.32mm | 1800 / 1500 N/5cm | HF / Hot Air | Indoor tent, banner keder |

| DF-KD450 | 500D × 500D | 450gsm | 0.42mm | 2000 / 1800 N/5cm | HF / Hot Air | Exhibition tents, sidewalls |

| DF-KD550 | 1000D × 1000D | 550gsm | 0.50mm | 2800 / 2500 N/5cm | HF / Hot Air | Awnings, industrial curtains |

| DF-KD650 | 1000D × 1000D | 650gsm | 0.56mm | 3000 / 2600 N/5cm | HF / Hot Air | Heavy-duty tents & structures |

| DF-KD750 | 1000D × 1000D | 750gsm | 0.62mm | 3500 / 3200 N/5cm | HF / Hot Air | Truck side curtain, industrial track systems |

Applications of Keder Tarpaulin

DERFLEX keder tarpaulin is widely used in the following industries:

- Event tents and marquees

- Awnings and sunshade systems

- Exhibition halls and industrial shelters

- Truck curtain side systems

- Large format banner and signage systems

- Inflatable structures

- Boat covers and marine equipment

1. Tent Keder & Marquee Structures

Designed for the high tension loads of aluminum tent frames.

2. Awnings & Pergolas

Provides smooth sliding and strong weather protection.

3. Truck Curtain Systems

Offers durability and long-term performance under continuous movement.

4. Banner & Advertising Frames

Ensures easy installation and perfect flat tensioning.

Custom Keder Tarpaulin Solutions

DERFLEX supports complete OEM/ODM services for keder fabric production.

Available Custom Options:

- Fabric weight: 300–800gsm

- PVC coating thickness

- Polyester yarn density

- Surface gloss level

- Embossing texture

- Color & printing

- Anti-UV, anti-cold, fire-retardant

- Core diameter customization

- Pre-welded keder with cord

Why Choose DERFLEX as Your Keder Tarpaulin Manufacturer?

1. 20+ Years Manufacturing Experience

Experts in PVC coated fabric, flexible materials, and industrial textiles.

2. Advanced Production Lines

- Multi-layer coating machines

- Lamination lines

- High-precision color mixing

- Digital embossing customization

3. Strict Quality Control

- Tensile/tear tests

- UV aging test

- Low-temperature bending

- High-frequency welding test

4. Global Export Capability

DERFLEX supplies clients in the USA, Germany, UK, Japan, Australia, Middle East, and South America.

5. OEM / ODM Support

Customized keder tarpaulin in small and large quantity production.

How to Order Keder Tarpaulin from DERFLEX

- Send your keder size / diameter requirements

- We recommend proper fabric and welding solution

- Free samples available for testing

- Confirm color, embossing, and coating

- Mass production: 7–15 days

- Shipping via sea, air, or express

Frequently Asked Questions (FAQ)

1. What is keder tarpaulin used for?

Keder tarpaulin is commonly used in tents, awnings, truck curtains, banners, and textile structures.

2. Can DERFLEX customize keder size?

Yes, the keder diameter and fabric thickness can be fully customized.

3. What is the difference between PVC and polyester keder?

PVC is stronger and more durable, while polyester keder is more flexible.

4. Does DERFLEX provide pre-welded keder?

Yes, DERFLEX provides welded keder with core ready for use.

5. Do you offer UV-resistant and fire-retardant options?

Yes, UV, FR, anti-cold, and anti-fungus formulations are available.