PTFE Fiberglass Architectural Membranes Manufacturer & Supplier

PTFE fiberglass architectural membranes represent the highest level of performance in permanent tensile architecture and membrane structure engineering. As a professional industrial textile and coated fabric manufacturer, DERFLEX supplies high-quality PTFE fiberglass membranes designed for iconic architectural projects, large-span roof systems and long-life membrane structures worldwide.

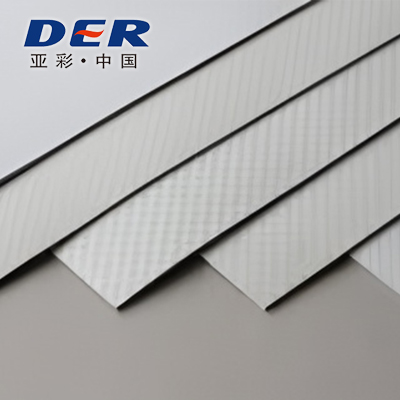

Combining a high-strength fiberglass base fabric with a polytetrafluoroethylene (PTFE) coating, these membranes deliver exceptional durability, structural stability, fire resistance and long-term aesthetic performance. DERFLEX PTFE architectural membranes are widely used in stadium roofs, airports, exhibition centers, transportation hubs and landmark architectural installations.

What Are PTFE Fiberglass Architectural Membranes?

PTFE fiberglass architectural membranes are composite materials consisting of a woven fiberglass fabric substrate coated with PTFE resin. The fiberglass base provides outstanding tensile strength and dimensional stability, while the PTFE coating offers unparalleled resistance to UV radiation, chemicals, fire, weathering and environmental pollution.

Unlike PVC coated polyester membranes, PTFE fiberglass membranes are designed for permanent architectural structures with service life expectations of 25–40 years or more. Their self-cleaning surface, non-stick characteristics and structural reliability make them the preferred choice for high-profile, long-term architectural applications.

Core Performance Characteristics

- Exceptional tensile strength and load-bearing capability

- Non-combustible fiberglass substrate

- Excellent fire resistance (Class A)

- Outstanding UV and weather resistance

- Self-cleaning and low maintenance surface

- Ultra-long service life for permanent structures

DERFLEX Expertise in PTFE Architectural Membrane Manufacturing

DERFLEX brings extensive experience in coated fabric manufacturing and technical textile engineering to the production of PTFE fiberglass architectural membranes. Our manufacturing process integrates advanced fiberglass weaving, PTFE coating technology and precision quality control systems.

From raw material selection to final inspection, each membrane roll is produced under strict standards to ensure consistent mechanical performance, coating integrity and surface quality suitable for demanding architectural projects.

Why Global Projects Choose DERFLEX

- Professional architectural membrane material supplier

- Strict quality control and testing procedures

- Stable long-term production capability

- Technical support for design and fabrication stages

- Global export and project supply experience

Technical Specifications of PTFE Fiberglass Architectural Membranes

| Parameter | Specification Range |

|---|---|

| Base Fabric | Woven Fiberglass Fabric |

| Coating Material | PTFE (Polytetrafluoroethylene) |

| Fabric Weight | 800 – 1500 GSM |

| Tensile Strength | Up to 9000 N / 5 cm |

| Fire Performance | Non-combustible / Class A |

| Light Transmission | 8% – 15% |

| Service Life | 25 – 40 Years |

All technical parameters can be optimized to meet specific architectural design requirements and regional building codes.

Architectural Applications of PTFE Fiberglass Membranes

Stadium & Sports Facilities

PTFE fiberglass architectural membranes are widely used in stadium roofs and sports complexes where long spans, structural safety and minimal maintenance are critical. Their lightweight nature reduces structural load while providing excellent weather protection.

Transportation Hubs

Airports, railway stations and transit terminals benefit from the fire safety, durability and natural daylight transmission of PTFE membrane structures, enhancing both safety and passenger experience.

Exhibition & Convention Centers

Large exhibition halls and convention centers utilize PTFE membranes to achieve iconic architectural forms while ensuring long-term operational reliability.

Landmark & Iconic Architecture

PTFE fiberglass membranes are often selected for landmark structures due to their clean appearance, long service life and ability to maintain aesthetic quality for decades.

Fire Resistance & Safety Advantages

Fire performance is a critical factor in permanent architectural structures. PTFE fiberglass architectural membranes offer superior fire safety due to their inorganic fiberglass base fabric and PTFE coating.

- Non-combustible fiberglass substrate

- No molten dripping under fire exposure

- Low smoke generation

- Compliance with international fire safety standards

These characteristics make PTFE membranes suitable for public buildings and high-occupancy facilities.

Weather Resistance & Long-Term Durability

DERFLEX PTFE fiberglass membranes demonstrate outstanding resistance to UV radiation, extreme temperatures, acid rain, pollution and environmental aging. The PTFE surface prevents dirt adhesion, allowing rainwater to naturally clean the membrane.

This self-cleaning property significantly reduces maintenance costs and ensures that architectural structures maintain their appearance over decades of service.

Design Flexibility & Structural Performance

PTFE fiberglass architectural membranes offer architects and engineers exceptional design freedom. Their high tensile strength and dimensional stability allow for complex curved forms, large-span structures and innovative architectural expressions.

The material’s predictable mechanical behavior supports precise structural calculations and long-term reliability.

Quality Control & Testing

Every PTFE fiberglass architectural membrane produced by DERFLEX undergoes comprehensive testing to ensure compliance with international standards and project specifications.

- Tensile strength testing

- Coating adhesion evaluation

- Fire resistance verification

- Light transmission measurement

- Accelerated aging tests

Customization & Project Support

DERFLEX provides customized PTFE fiberglass membrane solutions tailored to specific architectural and engineering requirements. Our technical team supports customers from material selection through fabrication and installation stages.

Custom options include fabric weight, light transmission, surface finish and roll width.

Global Supply Capability

DERFLEX supplies PTFE fiberglass architectural membranes to projects worldwide, serving membrane structure contractors, fabricators and engineering firms across Europe, North America, the Middle East, Asia and beyond.

Learn more about our architectural fabric solutions at: https://www.derflex.com

Frequently Asked Questions

What is the typical lifespan of PTFE fiberglass architectural membranes?

PTFE fiberglass membranes typically offer a service life of 25 to 40 years when properly designed, fabricated and installed.

Are PTFE membranes suitable for permanent structures?

Yes. PTFE fiberglass membranes are specifically engineered for permanent architectural structures requiring long-term durability and safety.

Does DERFLEX provide technical support for projects?

DERFLEX offers professional technical support, including material selection guidance and performance consultation for architectural projects.

Contact DERFLEX – PTFE Fiberglass Architectural Membranes

If you are searching for a reliable manufacturer and long-term supplier of PTFE fiberglass architectural membranes, DERFLEX is your trusted partner. Contact us today for technical details, samples and project quotations.