- tarp

- Frontlit banner

- PVC flex backlit

- Blockout banner

- PVC vinyl sticker

- Tarpaulin

- PVC mesh banner

- PVC preformated vinyl

- Reflective vinyl

- Dye Sublimation fabric

- PVC Stretch Ceiling Film

- Super clear pvc film

- PVC coated fabrics

- TPO coated fabric

- TPU coated fabric

- Automotive Protection Film

- Inkjet media

- Textile banner

- Mesh banners

- New Products

- customized PVC tarps products

- PVC Foam Board Sheet

- Profile download

- Services Hotline

+86-021-54361792 / 54361798 - Email

sales@derflex.com

|

|

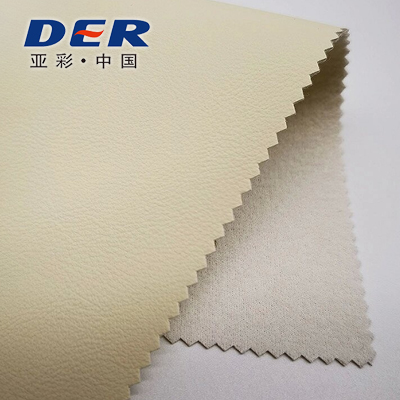

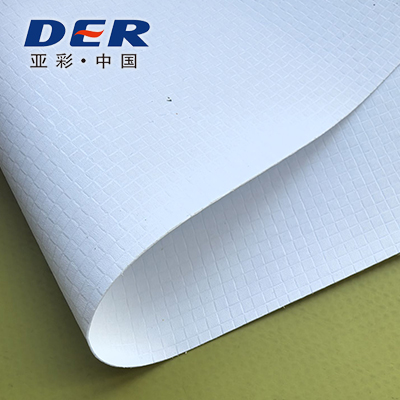

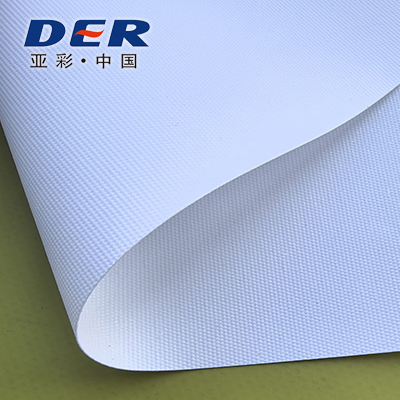

PVC Organ Cloth | PVC Coated Organ Fabric

DERFLEX PVC organ cloth (PVC coated organ fabric) — lightweight yet high-strength PVC coated polyester fabric with excellent waterproofing, UV resistance and easy fabrication. Ideal for tents, truck tarps, inflatable structures and industrial covers. Custom colors and technical options available.

|

|

||||||||||||||||||||||||||||

PVC Organ Cloth — PVC Coated Organ Fabric by DERFLEXDERFLEX PVC organ cloth (PVC coated organ fabric) is a high-performance coated textile engineered for outdoor and industrial use. Combining a high-tenacity polyester base with precision PVC coating technology, this fabric delivers excellent waterproofing, mechanical strength and long-term UV resistance while remaining easy to cut, weld and finish. Product OverviewPVC organ cloth is produced by applying a single-sided or double-sided PVC coating to a woven polyester (PET) base cloth. The coating process creates a composite material — often referred to as PVC coated organ fabric — that balances tensile performance with surface functionality. DERFLEX applies solvent-free and solvent-based coating formulas, available with optional additives such as anti-UV, anti-mildew, flame retardant and anti-static agents. Key benefits at a glanceExpertise, Authority & Trust — Why DERFLEXExpertise: DERFLEX has over 15 years of R&D and industrial experience in coated fabrics and membrane materials. Our technical team includes specialists in polymer chemistry, textile engineering and coatings formulation, enabling us to design PVC coated organ fabric solutions tailored to structural, transport and architectural applications. Authority: We manufacture on vertically integrated lines — from yarn selection and fabric weaving to coating, finishing and quality control — which gives us robust control over product consistency. DERFLEX routinely supplies global tent-makers, marquee fabricators, logistics providers and architectural membrane contractors. Trust: Every production batch undergoes in-line QC and final inspection that includes tensile testing, peeling strength, hydrostatic pressure testing and accelerated weathering. We provide batch traceability and third-party testing on request, and maintain transparent documentation for clients and regulatory audits. Technical Specifications (Typical Values)

Note: The values above are typical; exact performance depends on selected specification. DERFLEX will provide specification sheets and test reports on request. Available Colors & FinishesDERFLEX supplies standard colors as well as custom PANTONE color matching for branded projects. Standard color palette includes: Finishes: matte finish for reduced glare, glossy finish for architectural aesthetics, anti-dirt treatment and antimicrobial options for specialty use. Applications — Where to Use PVC Organ ClothDERFLEX PVC organ cloth (PVC coated organ fabric) is widely used across multiple sectors. Representative applications include: For each project DERFLEX can advise on best-suited weight, coating formulation (e.g., flame-retardant, low-temperature flexibility), and fabrication guidelines to meet safety and durability requirements. About DERFLEX — Shanghai DER New Materials Co., Ltd.DERFLEX is a specialist manufacturer of coated technical textiles and membrane materials with a vertically integrated production capacity. Our capabilities include yarn sourcing, weaving, coating formulation, lamination, finishing and inspection. For more than a decade DERFLEX has focused on creating high-quality PVC coated organ fabric products for global clients in events, logistics, architecture and industrial markets. We emphasize process control, product traceability and responsive technical support. Our team provides specification consulting, mock-up testing and engineering assistance during product selection and installation phases. Certifications & ComplianceDERFLEX maintains key quality and compliance systems and can provide relevant certificates upon request. Typical certifications and test documentation include: Note: Specific certificates (e.g., EN 13501 classification or NFPA/ASTM reports) can be supplied after product selection and testing agreement. Why Choose DERFLEX for Your PVC Coated Organ Fabric NeedsQuality & ConsistencyOur production lines are calibrated and controlled for repeatable thickness, coating weight and adhesion properties, ensuring fabric uniformity across large orders. Technical SupportWe provide technical data sheets, welding parameter guidance and onsite/remote support for complex projects so fabricators can achieve watertight seams and long service life. CustomizationFrom non-standard weights to special coatings (low-temperature flexibilizers, high-UV stabilizers, flame retardants), DERFLEX adapts the product to project-specific performance targets. Global LogisticsWe work with experienced freight partners to ship containerized or LCL consignments to clients worldwide, supporting export documentation and customs compliance. Installation & Handling PrecautionsMarkets & Export DestinationsDERFLEX PVC organ cloth and PVC coated organ fabric are exported worldwide. Representative export markets include: United States, Canada, United Kingdom, Germany, France, Italy, Spain, Netherlands, Sweden, Poland, Russia, Turkey, UAE, Saudi Arabia, Israel, India, South Korea, Japan, Australia, New Zealand, Brazil, Mexico, South Africa, and others. We tailor documentation and packaging to meet regional regulatory and customer requirements. Frequently Asked Questions (FAQs)Q1: What is the difference between "PVC organ cloth" and "PVC coated organ fabric"?A: The terms are commonly used interchangeably. Both refer to polyester base cloth coated with PVC. "PVC coated organ fabric" emphasizes the coating process; "PVC organ cloth" is a concise product name used in the industry. Q2: Can you produce flame-retardant PVC organ fabric?A: Yes. Flame-retardant formulations are available and can be tested to various standards (EN, ASTM or NFPA). Certification requires testing of production samples to confirm compliance with the requested classification. Q3: Do you offer sample rolls?A: Yes. Standard sample pieces are available for testing. Samples may incur a handling or courier fee. For larger sample trials, we can produce small trial rolls subject to MOQ and lead time. Q4: How do I choose the right weight for my application?A: Weight selection depends on application load, exposure and fabrication method. For tents and event fabrics, 350–450 gsm is common; for heavy-duty truck tarpaulins, 650–800 gsm is typical. Contact our technical team with your use case for a tailored recommendation. Q5: What is the lead time for production?A: Lead time depends on specification and order quantity. Typical lead times are 7–14 days for stocked standard items and 25–45 days for bulk or customized production. Confirmed lead times will be included in order confirmations. Q6: Are printed logos and custom patterns supported?A: Yes. DERFLEX supports full-width digital and rotary screen printing on PVC coated organ fabric. We recommend pre-production samples to verify color fidelity and ink adhesion. Contact DERFLEX — Samples & Technical SupportTo request samples, technical data sheets, or a quotation for PVC organ cloth (PVC coated organ fabric), please contact our sales team at sales@derflex.com or visit our contact page to submit an inquiry. Provide your application details (intended use, required width, estimated annual quantity, and any required certifications) so we can prepare a tailored solution. Contact DERFLEX Sales |

||||||||||||||||||||||||||||