PVC Roofing Membrane – High-Performance Waterproof Roofing Solutions

Manufacturer: DERFLEX

Official Website: https://www.derflex.com

What Is PVC Roofing?

PVC roofing (Polyvinyl Chloride Roofing Membrane) is a single-ply thermoplastic roofing system widely used in commercial, industrial, and architectural applications. It is engineered for superior waterproofing, long-term durability, UV resistance, chemical stability, and fire performance.

Unlike traditional roofing materials such as asphalt or bitumen, PVC roofing membranes are heat-welded at seams, forming a continuous, watertight barrier that resists leaks, weather aging, and environmental stress. This makes PVC roofing one of the most reliable flat and low-slope roofing solutions worldwide.

As a professional PVC roofing membrane manufacturer, DERFLEX designs and supplies reinforced and non-reinforced PVC roofing materials that meet international standards for modern construction projects.

Why Choose PVC Roofing Membranes?

1. Excellent Waterproof Performance

PVC roofing membranes are inherently waterproof. Heat-welded seams eliminate weak points, preventing water infiltration even under long-term exposure to heavy rain, snow, and standing water.

2. UV & Weather Resistance

DERFLEX PVC roofing materials are formulated with advanced UV stabilizers, ensuring long-term resistance to sunlight, thermal cycling, and outdoor aging. This significantly extends the service life of roofing systems.

3. Fire Resistance

PVC roofing membranes exhibit excellent fire retardant properties and comply with international fire safety standards, making them suitable for commercial and industrial buildings.

4. Chemical & Pollution Resistance

PVC roofs resist oils, acids, alkalis, industrial emissions, and airborne pollutants, making them ideal for factories, warehouses, logistics centers, and chemical plants.

5. Energy Efficiency

Light-colored PVC roofing membranes reflect solar radiation, reducing heat absorption and lowering cooling costs. This supports green building and energy-saving initiatives.

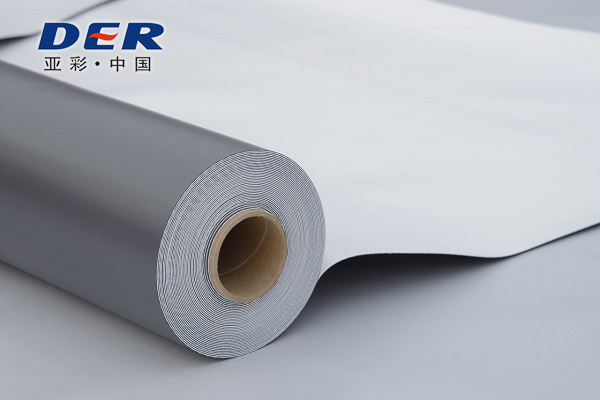

DERFLEX PVC Roofing Product Structure

DERFLEX PVC roofing membranes are engineered using a multi-layer composite structure:

- Top Layer: UV-resistant PVC compound with weather protection

- Reinforcement Layer: High-strength polyester scrim for dimensional stability

- Bottom Layer: Flexible PVC layer for excellent adhesion and waterproofing

This reinforced structure ensures superior tensile strength, tear resistance, and long-term stability under extreme environmental conditions.

Technical Specifications of PVC Roofing Membranes

| Property | Specification |

|---|---|

| Material | PVC (Polyvinyl Chloride) |

| Thickness | 1.2mm / 1.5mm / 1.8mm / Custom |

| Width | 1.0m – 3.0m |

| Length | 20m – 30m per roll |

| Reinforcement | Polyester Scrim |

| Fire Rating | B1 / Class A Available |

| UV Resistance | Excellent |

| Service Life | 15 – 30 Years |

Main Applications of PVC Roofing

PVC roofing membranes are widely used across multiple industries and building types:

- Commercial Buildings & Shopping Centers

- Industrial Factories & Warehouses

- Logistics & Distribution Centers

- Sports Arenas & Exhibition Halls

- Public Infrastructure Projects

- Green Roof & Energy-Saving Buildings

- Temporary & Modular Structures

Advantages of DERFLEX PVC Roofing

- Direct Manufacturer Supply

- Stable Quality & Consistent Performance

- OEM & Custom Color Options

- Global Export Experience

- Strict Quality Control System

- Professional Technical Support

DERFLEX has over a decade of experience in coated fabric and PVC membrane manufacturing, supplying roofing solutions to clients worldwide.

Installation Methods

PVC roofing membranes can be installed using various methods depending on project requirements:

- Mechanical Fastening System

- Fully Adhered System

- Ballasted Roofing System

- Heat Welding Seam Technology

Proper installation ensures optimal waterproofing and long-term roof performance.

Quality Standards & Certifications

DERFLEX PVC roofing materials comply with international quality and safety standards, including:

- ISO Quality Management System

- EN & ASTM Testing Standards

- Fire Retardant Certifications

- Environmental & ROHS Compliance

Why DERFLEX Is a Trusted PVC Roofing Manufacturer

DERFLEX is a professional manufacturer specializing in PVC coated fabrics and roofing membranes. With advanced production lines, strict QC systems, and global supply capability, we provide reliable PVC roofing solutions for long-term projects.

Our technical team continuously develops innovative materials to meet evolving building and environmental standards.

Frequently Asked Questions (FAQ)

Is PVC roofing suitable for flat roofs?

Yes, PVC roofing membranes are ideal for flat and low-slope roofs due to their waterproof and seam-welded structure.

How long does PVC roofing last?

High-quality PVC roofing membranes can last 20–30 years with proper installation and maintenance.

Can PVC roofing resist UV exposure?

DERFLEX PVC roofing membranes are UV stabilized and designed for long-term outdoor exposure.

Is PVC roofing environmentally friendly?

PVC roofing is recyclable and supports energy-efficient building designs.