- tarp

- Frontlit banner

- PVC flex backlit

- Blockout banner

- PVC vinyl sticker

- Tarpaulin

- PVC mesh banner

- PVC preformated vinyl

- Reflective vinyl

- Dye Sublimation fabric

- PVC Stretch Ceiling Film

- Super clear pvc film

- PVC coated fabrics

- TPO coated fabric

- TPU coated fabric

- Automotive Protection Film

- Inkjet media

- Textile banner

- Mesh banners

- New Products

- customized PVC tarps products

- PVC Foam Board Sheet

- Profile download

- Services Hotline

+86-021-54361792 / 54361798 - Email

sales@derflex.com

|

|

roof tarps

DERFLEX Roof Tarps — industrial-grade PVC & PE roof tarpaulins for emergency repairs, temporary roofing, construction protection and transport cover. Custom sizes, reinforced hems, UV-stable coatings and certified quality for global projects.

|

|

||||||||||||||||||||||||||||

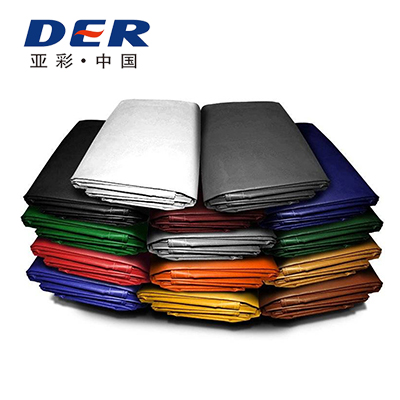

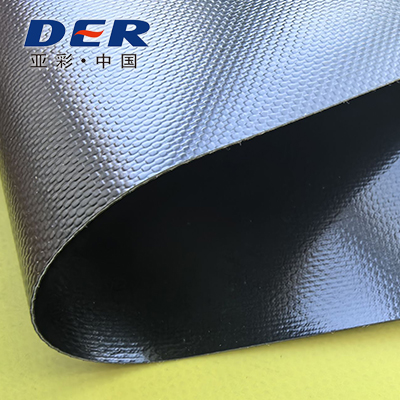

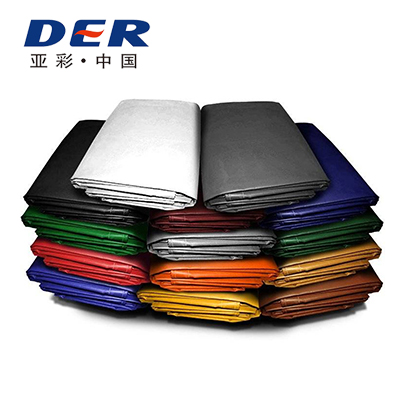

Roof Tarps — Heavy-Duty Roof Tarpaulins for Emergency Repair & Construction ProtectionDERFLEX roof tarps are engineered to provide reliable, long-lasting protection for damaged roofs, temporary roofing during construction, transport protection and emergency shelter. Trusted by contractors, roofing companies and disaster relief agencies worldwide. Product IntroductionDERFLEX Roof Tarps are premium-grade tarpaulins manufactured for roofing protection, emergency response and construction applications. Available in laminated PVC, coated polyester and woven PE constructions, our tarps combine superior waterproofing, UV stability and mechanical strength. Each roof tarp is designed to perform under severe weather — heavy rain, high winds, hail and prolonged UV exposure — while offering easy installation, secure anchoring options and custom features such as printed logos, clear windows and reinforced corners. Typical Use CasesCore BenefitsGoogle EEAT — Expertise • Experience • Authority • TrustExpertiseDERFLEX specializes in coated fabrics and technical tarpaulins. Our product engineering team includes materials scientists and field application engineers who design and validate roof tarps under both laboratory and field conditions. We tailor lamination, coating recipes and seam technology to meet roofing industry requirements. ExperienceWith over 15 years of experience supplying tarpaulins to construction, logistics and emergency relief projects, DERFLEX has delivered solutions to a range of climates and applications — from tropical storm zones to high-UV arid regions. Field feedback drives iterative improvements in product durability and installation features. AuthorityOur production follows ISO 9001 quality processes and we provide batch-level testing (tensile, tear, hydrostatic) by accredited laboratories. Customers receive datasheets, test certificates and compliance documentation for major procurement projects. TrustDERFLEX supports buyers with samples, on-demand testing, pre-shipment inspections and end-to-end logistics documentation to minimize procurement risk. Transparent warranty terms and responsive technical support build long-term partnerships. Product Parameters (Technical Specifications)Values below represent typical ranges. Exact test data and certificates are provided per SKU and production batch.

For projects with contractual test requirements, request an official datasheet and batch test reports prior to order placement. Product Colors & AppearanceStandard colors and recommended usage: Color fastness is influenced by coating type and exposure. DERFLEX supplies accelerated weathering data on request. Application Areas — Where Roof Tarps Perform BestEmergency & Disaster ResponseRapidly deployable DERFLEX tarps provide immediate watertight protection following storm, hail or wind damage. Lightweight roll formats and pre-fitted grommet patterns speed installation for relief teams. Construction & Temporary RoofingUsed to protect unfinished roofing decks, insulation and materials during staged construction, reroofing works, or when weather threatens to delay project schedules. Industrial & Commercial Roof ProtectionWarehouse and factory roofs under maintenance can be reliably covered with heavier GSM PVC tarps, protecting inventory and production equipment from water ingress. Transport & Cargo ProtectionFlatbed loads and rooftop shipments benefit from custom-cut tarps with tailored grommet layouts and reinforced tie-down points. Temporary Shelters & Field HousingIn relief or field scenarios, tarps can be quickly assembled into shelters, canopies or collective tarpaulin systems, providing immediate shelter and weatherproofing. DERFLEX — Company ProfileShanghai DER New Materials Co., Ltd. (DERFLEX) is a vertically integrated manufacturer of coated fabrics, specialized tarpaulins and technical membrane products. With advanced lamination lines, precision cutting, printing capabilities and a dedicated QC laboratory, DERFLEX serves international contractors, OEMs, distributors and humanitarian organizations. CapabilitiesCustomer SupportOur sales and technical teams provide specification consulting, sample programs, pre-shipment inspections and responsive after-sales support to ensure project requirements are met on time and within budget. Certifications & TestingDERFLEX supports quality-driven procurement with documented certifications and test reports. Common items provided with roof tarp orders include: Provide procurement specifications at RFQ stage to receive the exact certificates required for compliance. Why Choose DERFLEX Roof TarpsQuality & ConsistencyStrict QC at every production step ensures consistent mechanical and hydrostatic performance across batches. Customization & FlexibilityCustom sizes, reinforced corners, printed messaging and tailored reinforcement options allow you to get tarps that fit the project, not the other way around. Global Export ExperienceWe ship to more than 120 countries and provide full export documentation, incoterm guidance and logistics support for large orders. After-Sales & Technical SupportTechnical guides, installation best practices and maintenance kits are available to extend product life and reduce field failures. Installation Precautions & Maintenance TipsBefore InstallationDuring InstallationMaintenanceFor permanent or semi-permanent rooftop solutions, consult DERFLEX technical support for material upgrades and installation accessories. Sold To Countries — Global DistributionDERFLEX Roof Tarps are exported globally. Representative markets include: Contact local sales to confirm country-specific certifications, delivery terms and lead times. Frequently Asked Questions (FAQs)Q1: What material is best for long-term roof tarping?A: Laminated PVC in the 300–650gsm range with UV stabilizers and reinforced hems provides the best long-term performance for roof tarping and repeated outdoor exposure. Q2: Can you supply pre-cut tarps for specific roof sizes?A: Yes — DERFLEX offers cut-to-size finished tarps with customized grommet placement and reinforcement according to your roof dimensions. Q3: Are the tarps flame-retardant?A: Flame-retardant formulations are available on request. We can provide relevant test reports (EN/ASTM/NFPA) where needed for compliance. Q4: How are tarps packed and shipped?A: Standard packing is rolled and wrapped with protective film, labeled for export. Small orders may be folded into cartons. Shipping via sea, air or courier is available based on order size. Q5: Do you provide sample tarps for testing?A: Yes — sample programs are available. Freight or sample fees may apply depending on destination and sample size. Q6: What is the typical lead time?A: Typical production lead time is 10–30 days after order confirmation and deposit, depending on customization and order volume. Large or OEM projects may require longer lead times. Request Quote or SamplesTo request a quotation or samples, please provide the following: preferred material (PVC / PE), required weight (GSM), finished size, desired color, grommet spacing and any printing or reinforcement requirements. Our sales team will reply with a tailored quotation, sample availability and lead time. Request Quote / Request SamplesInclude project location and expected installation date for expedited support on urgent or emergency orders. |

||||||||||||||||||||||||||||