Tensile Fabric Roof Structures – Advanced Architectural Membrane Solutions by Derflex

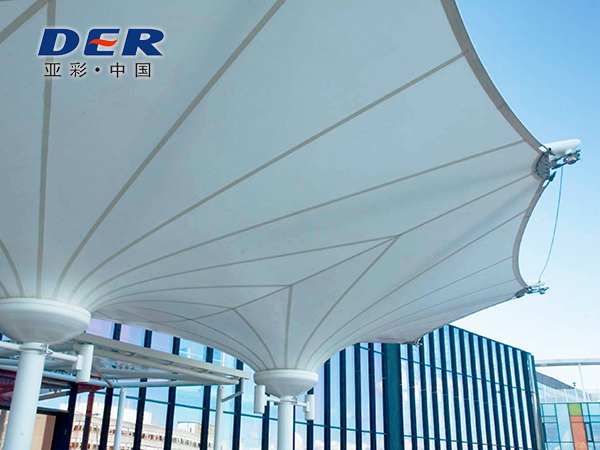

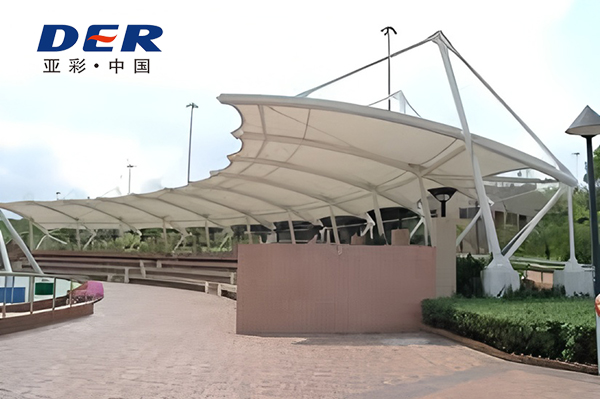

Tensile fabric roof structures represent a revolutionary approach to modern architecture, combining lightweight engineering, elegant aesthetics, and outstanding structural performance. As a leading manufacturer and global supplier of architectural fabrics, Derflex delivers high-performance tensile membrane materials designed to meet the evolving demands of architects, engineers, and project developers worldwide.

With decades of experience in coated textile manufacturing, Derflex tensile fabric roofing solutions are engineered for durability, weather resistance, and long-span architectural applications. These structures are widely used in stadiums, airports, exhibition halls, commercial complexes, transportation hubs, and iconic public spaces.

What Are Tensile Fabric Roof Structures?

Tensile fabric roof structures, also known as tensile membrane structures, are roofing systems that rely on tension rather than compression to maintain their shape and stability. Unlike traditional rigid roofing systems, tensile roofs use flexible membrane materials that are prestressed and supported by steel frameworks, cables, or masts.

This structural principle allows tensile fabric roofs to span large areas with minimal supporting elements, creating open, column-free spaces while achieving visually dynamic architectural forms.

Core Components of Tensile Membrane Roof Systems

1. Architectural Membrane Fabrics

The membrane is the most critical element of tensile fabric roof structures. Derflex supplies a wide range of architectural fabrics engineered specifically for tensile applications:

- PVC Coated Polyester Fabric

- PVDF Surface Treated Membranes

- PTFE Coated Fiberglass Fabric

- ETFE Foil Systems

2. Structural Support Systems

Steel frames, masts, arches, and tensioned cable networks work together to transfer loads efficiently while maintaining the membrane’s tension and shape.

3. Connection & Fixing Systems

High-strength fittings, edge cables, clamping plates, and custom detailing ensure safe load transfer and long-term stability.

Key Advantages of Tensile Fabric Roof Structures

- Lightweight Construction: Up to 70% lighter than conventional roofing materials

- Large Span Capability: Ideal for stadiums and large public spaces

- Architectural Freedom: Organic shapes and iconic designs

- Energy Efficiency: High reflectivity and natural daylight transmission

- Durability: UV, weather, and chemical resistance

- Cost Efficiency: Reduced foundation and structural steel requirements

Derflex Tensile Fabric Materials for Roof Structures

PVC Coated Polyester Fabric

PVC-coated polyester membranes are the most widely used materials in tensile fabric roof structures due to their excellent balance of flexibility, strength, and cost efficiency. Derflex PVC membranes feature advanced coating technology for long-term outdoor exposure.

PTFE Coated Fiberglass Fabric

PTFE membranes offer exceptional durability and service life exceeding 30 years. With outstanding fire resistance and self-cleaning properties, PTFE fabric roofs are commonly used in landmark projects.

ETFE Foil Roofing Systems

ETFE provides ultra-lightweight, high-transparency roofing solutions ideal for stadiums, botanical gardens, and atriums. ETFE roofs enable superior daylight transmission and thermal performance.

Applications of Tensile Fabric Roof Structures

- Sports stadiums and arenas

- Airports and transportation terminals

- Shopping malls and commercial centers

- Exhibition halls and convention centers

- Canopies and entrance roofs

- Cultural landmarks and public plazas

- Industrial and logistics buildings

Performance Standards and Compliance

Derflex tensile fabric roof materials are manufactured in compliance with international standards, ensuring reliability and safety across global markets:

- ISO Quality Management Systems

- Fire Retardancy: EN 13501, DIN 4102, NFPA 701

- UV Resistance and Weathering Tests

- Tensile Strength and Tear Resistance

Design Flexibility and Customization

Every tensile fabric roof structure project is unique. Derflex offers full customization options, including membrane thickness, color, translucency, coating type, and surface finishes to meet specific architectural and climatic requirements.

Sustainability and Environmental Benefits

Tensile fabric roof structures contribute to sustainable construction practices by reducing material consumption, lowering transportation emissions, and improving natural daylight utilization. Many Derflex membranes are recyclable and designed for long-term reuse.

Why Choose Derflex for Tensile Fabric Roof Structures?

- Decades of manufacturing expertise

- Advanced coating and textile technologies

- Global supply capability

- Strict quality control and testing

- Technical support for architects and engineers

Frequently Asked Questions

Are tensile fabric roof structures suitable for extreme climates?

Yes. Derflex tensile membranes are engineered to withstand high wind loads, heavy rain, snow, and intense UV exposure, making them suitable for diverse climatic conditions worldwide.

How is maintenance handled?

Most tensile fabric roofs require minimal maintenance due to self-cleaning coatings and dirt-resistant surface treatments.

Can tensile roofs be used for permanent buildings?

Absolutely. Modern tensile fabric roof structures are designed as permanent architectural solutions with long service lives.

Contact Derflex for Tensile Fabric Roof Solutions

If you are planning a tensile fabric roof structure project, Derflex offers expert consultation, material selection guidance, and high-performance architectural membranes tailored to your needs.

Visit our official website: https://www.derflex.com