Membrane Materials Used for Air-Supported Badminton Courts

DERFLEX – Professional Manufacturer & Supplier of Sports Membrane Materials

Overview: Air-Supported Badminton Courts and Membrane Materials

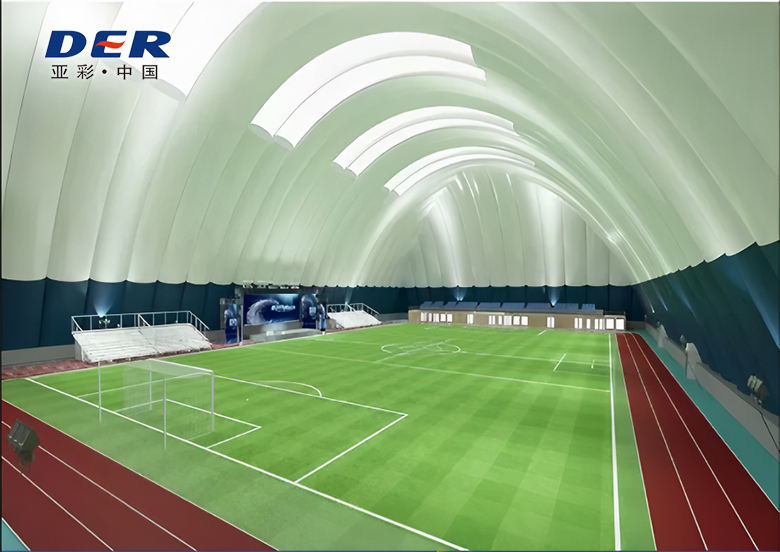

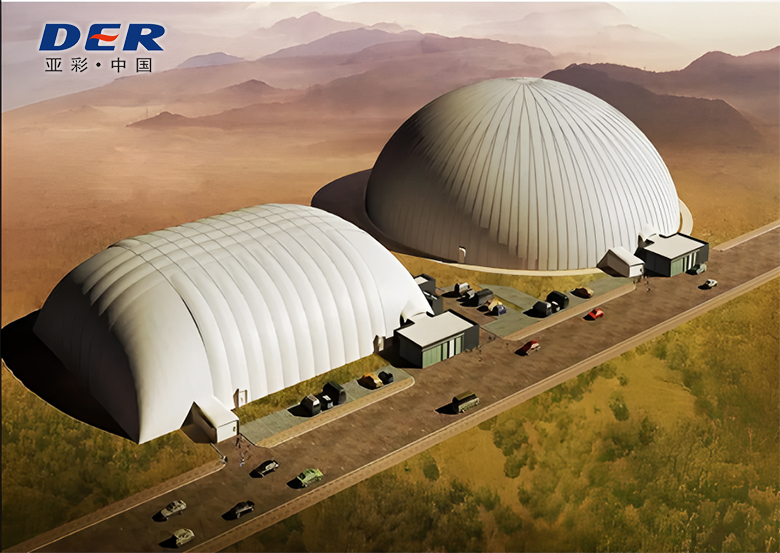

Air-supported badminton courts represent a modern, efficient, and cost-effective solution for indoor sports facilities. Unlike traditional steel or concrete buildings, air-supported structures rely entirely on internal air pressure to maintain shape and stability. The core material enabling this system is the high-performance membrane fabric.

As a professional membrane material manufacturer, DERFLEX supplies engineered membrane fabrics specifically designed for air-supported badminton courts, sports domes, and multi-purpose inflatable halls.

These membrane materials must meet strict requirements including airtightness, tensile strength, fire resistance, weather durability, and long-term dimensional stability. DERFLEX membrane solutions are engineered to meet international sports and building standards.

What Is an Air-Supported Badminton Court?

An air-supported badminton court is a fully enclosed sports facility constructed using membrane materials that are stabilized by constant internal air pressure. The structure eliminates the need for internal columns or heavy steel frames, creating a large, unobstructed playing space ideal for badminton training and competitions.

Air-supported badminton courts are widely used for:

- Professional badminton training centers

- Sports clubs and community gyms

- School and university sports halls

- Temporary or seasonal sports facilities

- Multi-court badminton domes

Why Membrane Materials Are Critical for Air-Supported Structures

The membrane material is the structural backbone of an air-supported badminton court. Unlike conventional roofing materials, membrane fabrics must perform multiple functions simultaneously:

- Maintain airtight enclosure

- Withstand internal air pressure

- Resist wind, snow, and external loads

- Provide fire safety compliance

- Offer thermal and acoustic performance

- Allow sufficient daylight diffusion

DERFLEX membrane materials are engineered to deliver balanced performance across all these critical dimensions.

Types of Membrane Materials Used for Air-Supported Badminton Courts

PVC Coated Polyester Membrane

PVC coated polyester membrane is the most commonly used material for air-supported badminton courts. It offers an optimal balance between mechanical strength, flexibility, airtightness, and cost efficiency.

- High-tenacity polyester base fabric

- Double-sided PVC coating

- Excellent weldability for airtight seams

- Customizable thickness and weight

PVDF Surface Treated Membrane

For long-term sports domes, PVDF surface treatment is applied to enhance durability and self-cleaning properties.

- Superior UV resistance

- Improved dirt and stain resistance

- Reduced maintenance costs

- Extended service life

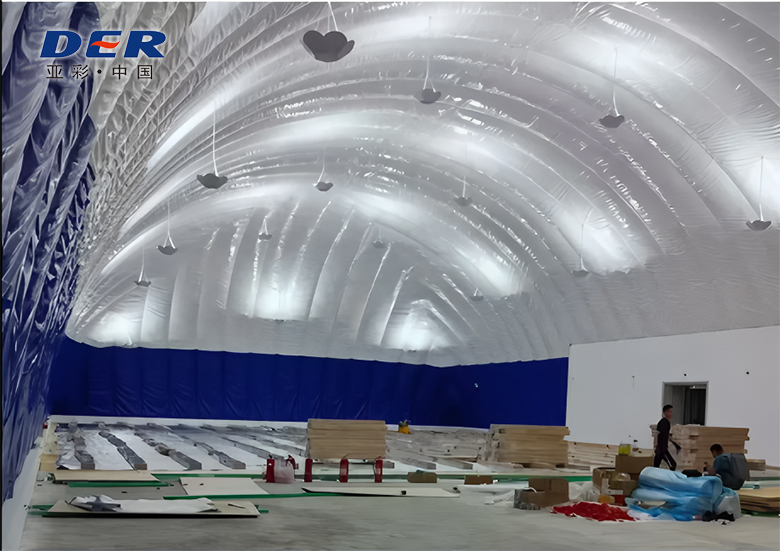

Insulated Double-Layer Membrane Systems

Many air-supported badminton courts use double-layer membrane systems with an air insulation cavity. This design significantly improves thermal insulation and energy efficiency.

- Inner airtight membrane layer

- Outer weather-resistant membrane layer

- Enhanced temperature control

- Lower heating and cooling costs

Key Performance Requirements for Badminton Court Membrane Materials

Airtightness

Airtight performance is the most critical requirement for air-supported structures. DERFLEX membrane materials feature low air permeability and high-quality welding compatibility to ensure long-term pressure stability.

Tensile Strength & Tear Resistance

The membrane must withstand continuous internal pressure, wind loads, and snow accumulation. DERFLEX membranes use high-tenacity yarns and optimized coating formulations to achieve excellent tensile and tear strength.

Fire Retardancy

Safety is essential for public sports facilities. DERFLEX supplies membrane materials that comply with international fire standards such as:

- EN 13501

- DIN 4102 B1

- NFPA 701

- BS 7837

Weather & UV Resistance

Outdoor air-supported badminton courts require membranes capable of resisting UV radiation, rain, snow, temperature fluctuations, and aging.

DERFLEX membranes are formulated for long-term outdoor exposure.

Advantages of DERFLEX Membrane Materials for Air-Supported Badminton Courts

- High airtight performance

- Excellent mechanical strength

- Stable dimensional behavior

- Long service life (10–20+ years)

- Low maintenance requirements

- Custom color and translucency options

Each membrane roll undergoes strict quality control and testing before delivery.

Manufacturing Expertise Behind DERFLEX

DERFLEX is a manufacturing-driven enterprise specializing in coated technical textiles. Unlike trading companies, we maintain full control over:

- Base fabric weaving

- PVC coating formulation

- Surface treatment processes

- Quality inspection and testing

Production Capabilities

- Advanced PVC coating lines

- Knife-over-roll coating technology

- High-frequency welding compatibility

- In-house testing laboratories

EEAT: Expertise, Experience, Authority, Trust

- Years of experience in sports membrane materials

- Global project references across multiple climates

- Stable long-term supply capability

- Transparent technical data and certifications

DERFLEX membrane materials are trusted by sports dome manufacturers, engineering contractors, and developers worldwide.

Applications Beyond Badminton Courts

- Air-supported football domes

- Tennis air domes

- Multi-purpose sports halls

- Swimming pool air structures

- Exhibition and event domes

Comparison: Air-Supported Membrane Structure vs Traditional Buildings

| Factor | Air-Supported Membrane | Steel Structure | Concrete Building |

|---|---|---|---|

| Construction Time | Very Fast | Medium | Slow |

| Weight | Very Light | Heavy | Very Heavy |

| Span | Large, Column-Free | Limited | Limited |

| Cost Efficiency | High | Medium | Low |

Global Supply & Technical Support

DERFLEX supplies membrane materials for air-supported badminton courts worldwide. Our services include:

- Bulk membrane roll supply

- Project-based specifications

- Export packaging and logistics

- Technical consultation