Double-Membrane Covers – High-Performance Membrane Roofing Solutions

As a professional coated textile manufacturer, DERFLEX supplies advanced double-membrane covers engineered for airtight containment, thermal insulation and long-term structural stability. Our double membrane systems are widely used in biogas plants, wastewater treatment facilities, agricultural storage, and industrial gas holders.

What Is a Double-Membrane Cover?

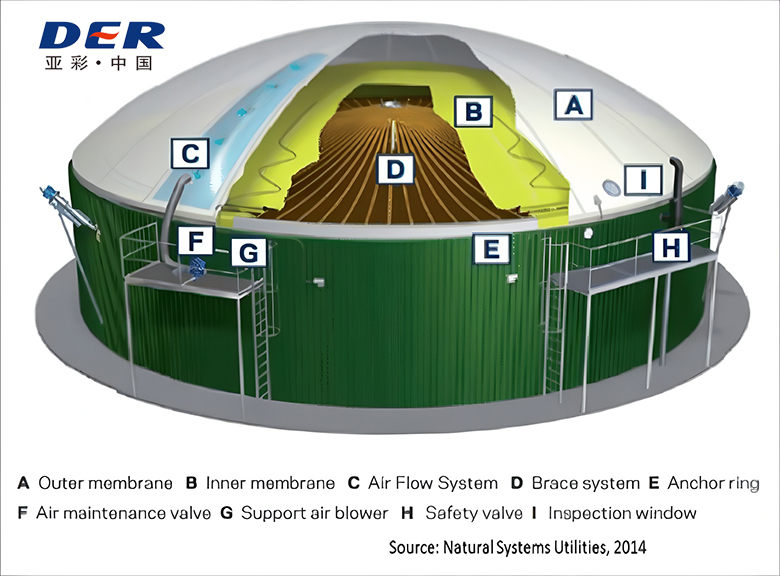

A double-membrane cover is a specialized tensile membrane structure consisting of two independent membrane layers: an inner gas-tight membrane and an outer protective membrane. Between these two layers, a controlled air pressure system forms an insulating air cushion that stabilizes the structure and improves energy efficiency.

Unlike single-layer membrane covers, double-membrane systems offer enhanced durability, superior thermal performance and reliable gas containment. This makes them an ideal solution for anaerobic digestion tanks, biogas storage domes, sludge tanks, and industrial reservoirs.

DERFLEX Double-Membrane Cover Structure

1. Inner Membrane (Gas-Tight Layer)

The inner membrane is designed for complete airtightness and chemical resistance. It directly contains biogas or process gases and must withstand continuous exposure to methane, hydrogen sulfide, moisture, and varying internal pressures.

- High-tenacity polyester base fabric

- PVC or PVDF coating for gas impermeability

- Excellent resistance to biogas corrosion

- Long-term flexibility under cyclic pressure

2. Outer Membrane (Weather Protection Layer)

The outer membrane protects the system from environmental exposure such as UV radiation, wind loads, rain, snow, and temperature fluctuations.

- UV-stabilized PVC coated fabric

- High tensile strength and tear resistance

- Self-cleaning surface options available

- Custom colors and surface finishes

3. Insulating Air Layer

A constant low-pressure air layer is maintained between the two membranes using a blower system. This air cushion improves thermal insulation, reduces condensation, and enhances structural stability.

Key Advantages of DERFLEX Double-Membrane Covers

Superior Airtight Performance

DERFLEX double-membrane covers are engineered to achieve extremely low gas permeability. This ensures minimal methane loss, improved biogas yield, and compliance with strict environmental regulations.

Thermal Insulation & Energy Efficiency

The insulating air layer significantly reduces heat loss, helping maintain optimal digestion temperatures and lowering overall energy consumption in biogas systems.

Long Service Life

With high-quality coated textiles and advanced welding technology, DERFLEX membrane covers typically achieve a service life of 15–20 years under proper operating conditions.

Low Maintenance Requirements

Smooth coated surfaces resist dirt accumulation, chemical corrosion and microbial growth, reducing maintenance costs over the system’s lifecycle.

Typical Applications

Biogas Plants

Double-membrane covers are extensively used in agricultural and industrial biogas plants as digester roofs and gas storage domes. They provide reliable gas containment while accommodating fluctuating gas volumes.

Wastewater Treatment Facilities

In municipal and industrial wastewater treatment, double-membrane covers help control odors, capture biogas, and protect tanks from weather exposure.

Agricultural Storage

Used for slurry tanks and manure storage, membrane covers reduce ammonia emissions, prevent rainwater ingress, and improve environmental compliance.

Industrial Liquid & Gas Storage

Double-membrane structures are suitable for various industrial storage applications where airtightness and weather resistance are critical.

Material Specifications

| Parameter | Specification Range |

|---|---|

| Base Fabric | High-tenacity polyester |

| Coating | PVC / PVDF / Acrylic |

| Total Weight | 750 – 1500 g/m² |

| Tensile Strength | Up to 5000 N / 5 cm |

| Temperature Resistance | -30°C to +70°C |

| UV Resistance | ≥ 10 years outdoor exposure |

Manufacturing & Quality Control

DERFLEX operates advanced coating, laminating, and high-frequency welding lines to ensure consistent membrane quality. Each double-membrane cover material batch undergoes strict quality inspections, including tensile testing, gas permeability testing, and weathering simulation.

Our production processes comply with international quality standards, ensuring stable performance for global engineering projects.

Why Choose DERFLEX as Your Double-Membrane Cover Supplier?

- Over 20 years of coated textile manufacturing experience

- In-house R&D and material customization

- Stable quality and large-scale production capacity

- Global export experience to Europe, Americas, Middle East and Asia

- Technical support for engineering and installation partners

By choosing DERFLEX, you work directly with a manufacturer that understands both material science and real-world application requirements.

Frequently Asked Questions (FAQ)

How long does a double-membrane cover last?

Under normal operating conditions, DERFLEX double-membrane covers typically last 15–20 years depending on environment and maintenance.

Can DERFLEX customize membrane size and thickness?

Yes. We provide full customization including fabric weight, coating type, color, and mechanical performance.

Are your membranes suitable for harsh climates?

Our membranes are designed to withstand UV exposure, wind loads, snow loads, and wide temperature ranges.