What Is Heavy-Duty PVC Fabric Roll?

Heavy-duty PVC fabric roll is a reinforced vinyl-coated textile designed for industrial-grade strength, long-term durability, and extreme outdoor stability. Manufactured from high-tenacity polyester base cloth and coated with premium-grade polyvinyl chloride (PVC), it delivers exceptional performance in applications such as truck tarps, industrial curtains, construction covers, container shelters, awnings, tents, and protective outdoor equipment.

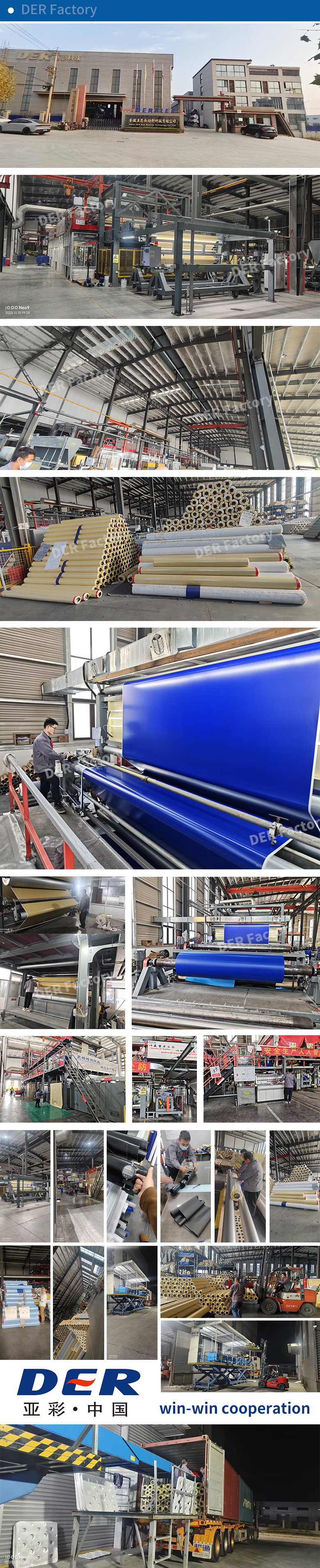

As a global manufacturer with over 20 years of production experience, DERFLEX (https://www.derflex.com) supplies a full series of heavy-duty PVC fabric rolls, ranging from 300gsm lightweight tarpaulin to 2000gsm extra-thick industrial vinyl.

Main Features of Heavy-Duty PVC Fabric Roll

- ✔ High tensile & tear strength – suitable for heavy-load and industrial environments

- ✔ 100% waterproof – prevents water leakage, suitable for outdoor covers

- ✔ Anti-UV & anti-aging – long-lasting color and material stability

- ✔ Fire retardant (optional) – meets B1, B2, NFPA 701 standards

- ✔ Anti-mildew & anti-fungal – maintains cleanliness in humid conditions

- ✔ Easy to weld – supports high-frequency welding, hot air welding, and hot wedge welding

- ✔ Wide temperature range – suitable for -30°C to +70°C environments

- ✔ Multiple color options – custom colors available on request

Technical Specifications

| Item | Specification |

|---|---|

| Material | PVC coated polyester fabric |

| Thickness | 0.3mm – 2.0mm (customizable) |

| Weight | 300gsm – 2000gsm |

| Tensile Strength | 1500–6000 N/5cm (warp/weft) |

| Tear Strength | 150–800 N |

| Coating Technology | Lamination or knife coating |

| Surface Treatment | Acrylic, lacquer, matte, glossy |

| Flame Retardant | B1 / B2 / M2 / NFPA 701 (optional) |

| Temperature Resistance | -30°C to +70°C |

| Standard Width | 1.02m / 1.5m / 1.83m / 2m / 3.2m |

| Color | Customizable |

| Roll Length | 30m / 50m / 100m or custom |

DERFLEX Production Process

- High-tenacity polyester yarn selection

- Weaving into base cloth

- PVC coating using lamination or knife coating

- Surface treatment (glossy/matte/acrylic)

- Cooling & tension control

- Trimming and quality inspection

- Roll packaging & labeling

Customization Options

DERFLEX offers full customization based on industry requirements:

- Custom color (RAL color matching)

- Custom GSM (300gsm–2000gsm)

- Anti-slip textures

- Printable surface for branding

- Extra UV protection

- Low-temperature resistance

- Fire retardant formula

- Roll width & length customization

Packing & Global Shipping

Standard packing includes:

- Hard paper roll core

- Protective PE film

- Label with batch number

- Pallet packing for protection during long-distance transport

We ship globally to Europe, USA, Australia, South America, Middle East, and Asia.

FAQ – Heavy-Duty PVC Fabric Roll

1. What GSM should I choose?

300–600gsm for lightweight covers, 650–900gsm for truck tarps, 1000–2000gsm for industrial use.

2. Can PVC fabric be printed?

Yes, it is compatible with eco-solvent, UV, and latex printing.

3. How many years can it last?

Outdoor lifespan is 3–10 years depending on GSM and UV exposure.

4. Can DERFLEX produce fire-retardant PVC fabric?

Yes, we offer B1, B2, M2, and NFPA 701 flame-retardant formulations.

5. Do you offer free samples?

Yes, free A4 samples are available for global customers.