Reinforced PVC Material – High-Strength PVC Coated Fabric for Industrial Applications

DERFLEX manufactures high-performance reinforced PVC material engineered for demanding industrial, commercial, military, and environmental applications. With excellent strength, waterproofing, UV resistance, and custom manufacturing options, our reinforced PVC fabrics are trusted worldwide for durable, long-term performance.

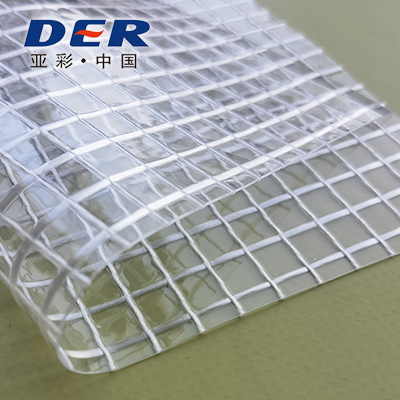

What Is Reinforced PVC Material?

Reinforced PVC material is a composite fabric consisting of a high-tenacity polyester mesh (scrim) coated or laminated with flexible polyvinyl chloride (PVC). The reinforcement provides structural stability, tear resistance, and dimensional strength, while the PVC coating delivers waterproofing, chemical resistance, UV stability, and long-lasting durability.

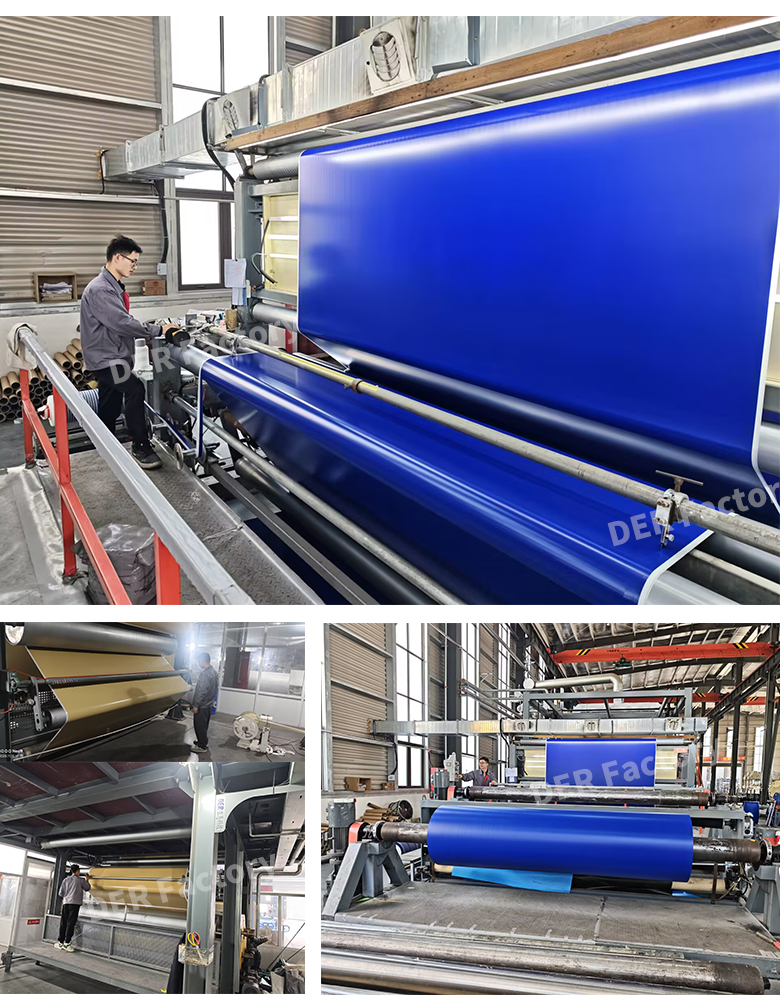

At DERFLEX, we produce reinforced PVC materials using advanced coating and lamination technologies:

- Knife coating

- Lamination / hot-melt lamination

- Calender coating

- Multi-layer reinforcement technologies

These processes ensure consistent physical performance, strong adhesion between layers, and superior weather resistance—ideal for tarpaulins, construction structures, truck side curtains, tents, canopies, and a wide range of industrial uses.

Main Features of DERFLEX Reinforced PVC Material

1. High Tensile and Tear Strength

The embedded polyester fabric acts as a structural backbone, significantly increasing load-bearing capacity and providing outstanding resistance to tearing, stretching, and mechanical stress. This makes DERFLEX reinforced PVC ideal for heavy-duty and long-term outdoor use.

2. 100% Waterproof and Weatherproof

PVC coatings provide complete protection against water, moisture, and humidity. Even under continuous rain, immersion, or extreme weather, the material maintains waterproofing capabilities without delamination.

3. UV, Heat, and Cold Resistance

Reinforced PVC can withstand prolonged outdoor UV exposure and extreme temperatures:

- Heat resistance: up to +70°C

- Cold resistance: down to -30°C or lower (depending on grade)

- Anti-aging formulation for sunny and high-altitude regions

4. Flame-Retardant Options

For applications requiring fire safety certification, DERFLEX offers flame-retardant grades compliant with:

- B1

- M2

- NFPA701

- EN13501-1 (upon request)

5. Chemical and Abrasion Resistance

Suitable for industrial facilities, chemical environments, and marine exposure. Reinforced PVC resists:

- Acids and alkalis

- Saltwater and moisture

- Industrial oils

- Surface abrasion and friction damage

6. Easy Welding and Fabrication

Reinforced PVC is compatible with:

- Hot-air welding

- High-frequency welding

- Solvent welding

- Sewing, bonding, or heat sealing

Ideal for large-area structures, covers, and modular fabrication.

7. Wide Range of Customization Options

DERFLEX offers complete custom manufacturing:

- Thickness: 0.3mm–1.8mm

- Base fabric: 200D–2000D

- Reinforcement patterns: plain, grid, strong mesh

- Surface style: matte, gloss, embossed, anti-slip

- Colors: any Pantone color available

- Roll sizes and lengths

- Special coatings: anti-fungal, anti-static, flame-retardant

Reinforced PVC Material Specifications

| Property | Value |

|---|---|

| Thickness | 0.3mm – 1.8mm (custom) |

| Weight | 260g – 1200g/m² |

| Base Fabric | Polyester 200D–2000D |

| Width | 1.02m – 3.20m |

| Tensile Strength | 1200–3500 N/5cm |

| Tear Strength | 150–450 N |

| Temperature Resistance | -30°C to +70°C |

| Surface Type | Matte / Glossy / Embossed |

| Flame Retardant | B1, M2, NFPA701 (optional) |

| UV Stability | 5–15 years |

| Color | All colors available |

Applications of Reinforced PVC Material

Due to its outstanding strength, flexibility, waterproofing, and long-term weather resistance, reinforced PVC material is widely used in industrial, construction, agricultural, marine, military, and environmental protection industries.

1. Tarpaulins & Heavy-Duty Covers

- Truck tarpaulins

- Industrial equipment covers

- Construction site covers

- Warehouse partition curtains

2. Tent & Shelter Fabric

- Commercial tents

- Military tents

- Disaster relief shelters

- Event canopies

3. Marine & Water Applications

- Boat covers

- Dockyard covers

- Inflatable structures

4. Agricultural Uses

- Crop covers

- Agricultural curtains

- Greenhouse fabric

5. Building & Construction

- Scaffolding covers

- Temporary roofing

- Building façade material

DERFLEX – Your Trusted Manufacturer of Reinforced PVC Materials

With over 20 years of experience, DERFLEX is a leading manufacturer of PVC coated fabrics, reinforced PVC materials, tarpaulins, geomembranes, and industrial flexible materials. Our factory operates multiple coating and lamination lines with strict quality control systems that ensure global-standard stability and long service life.

Our reinforced PVC materials are supplied to more than 80 countries and used in construction engineering, logistics, agriculture, transportation, industrial manufacturing, and environmental protection industries.

To learn more, visit https://www.derflex.com/.

FAQ – Reinforced PVC Material

1. What is reinforced PVC material?

Reinforced PVC material is a polyester mesh fabric coated with PVC for high strength and waterproof performance.

2. What is reinforced PVC used for?

It is commonly used for tarpaulins, tents, truck covers, boat covers, industrial curtains, and construction applications.

3. Can DERFLEX customize reinforced PVC fabrics?

Yes. Thickness, color, coating type, reinforcement density, and roll width can all be customized.

4. Is reinforced PVC waterproof?

Yes, PVC-coated materials are fully waterproof and weather-resistant even under long-term outdoor conditions.

5. What is the service life of reinforced PVC material?

Typically 5–15 years depending on UV grade and application environment.