Professional Tensile Fabric Supplier for Architectural & Industrial Applications

DERFLEX – A Global Tensile Fabric Supplier You Can Trust

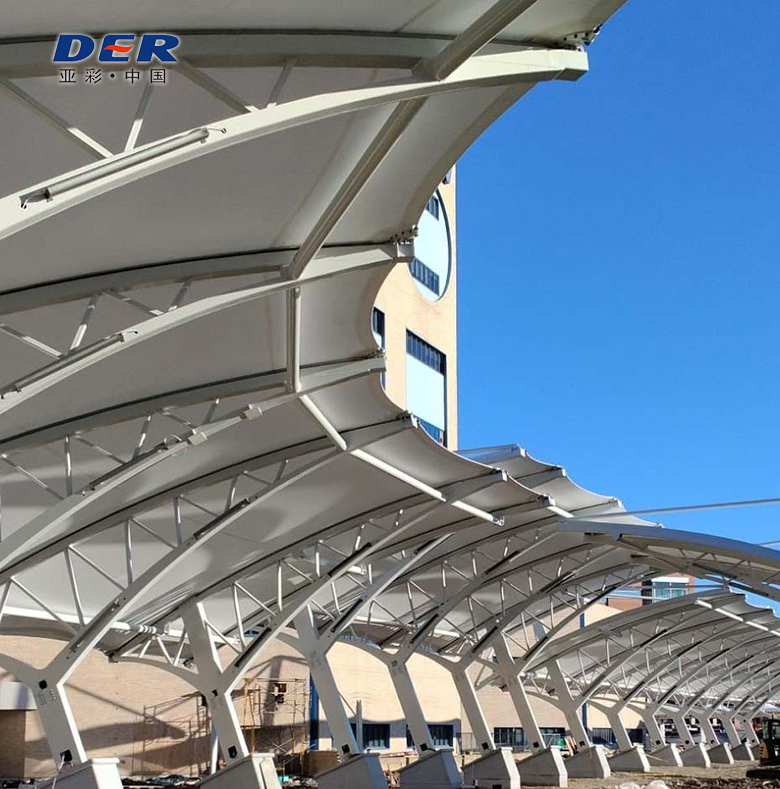

As modern architecture continues to evolve toward lightweight, sustainable, and visually dynamic structures, tensile fabrics have become a core material in contemporary design. DERFLEX stands at the forefront of this industry as a professional tensile fabric supplier with decades of manufacturing expertise.

From large-span architectural membrane structures to industrial roofing, shading systems, and tensile façades, DERFLEX delivers advanced coated fabric solutions engineered for strength, durability, and long-term performance.

Our tensile fabrics are trusted by architects, engineers, fabricators, and project developers in more than 100 countries.

What Is Tensile Fabric?

Tensile fabric is a high-strength technical textile designed to work primarily under tension rather than compression. It is commonly used in membrane structures where flexibility, lightweight construction, and large-span coverage are required.

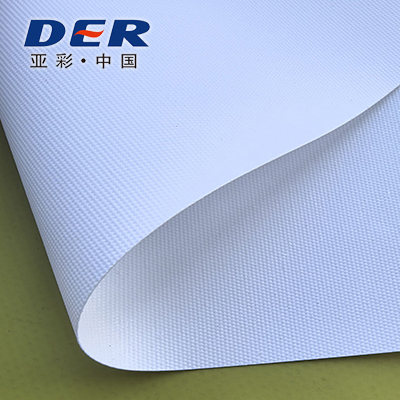

DERFLEX tensile fabrics are typically manufactured using high-tenacity polyester base cloth combined with advanced coating technologies such as PVC, PVDF, or PTFE.

This engineered composition allows tensile fabric structures to achieve exceptional load-bearing capacity, weather resistance, and design freedom.

Types of Tensile Fabrics Supplied by DERFLEX

PVC Coated Tensile Fabric

PVC coated tensile fabric is the most widely used material for membrane structures due to its cost-effectiveness, flexibility, and strong mechanical properties.

- High tensile strength

- Excellent weldability

- Wide color availability

- Suitable for permanent and semi-permanent structures

PVDF Tensile Membrane Fabric

PVDF surface treatment enhances self-cleaning properties and UV resistance, making it ideal for long-term architectural projects.

- Superior dirt resistance

- Extended service life

- Improved weatherability

PTFE Tensile Fabric

PTFE coated fiberglass fabric represents the highest performance category of tensile membranes, often used in landmark architectural structures.

- Exceptional fire resistance

- Service life exceeding 25–30 years

- Outstanding chemical and UV stability

Key Performance Advantages of DERFLEX Tensile Fabrics

- High tensile and tear strength

- Excellent dimensional stability

- Resistance to UV radiation and aging

- Waterproof and mildew resistant

- Customizable surface finishes

Each tensile fabric roll supplied by DERFLEX undergoes strict quality inspection to ensure consistent performance across large-scale projects.

Applications of Tensile Fabric Structures

- Architectural membrane roofs

- Stadiums and sports facilities

- Airport terminals and transport hubs

- Commercial canopies and walkways

- Car parking shade structures

- Industrial warehouses and storage shelters

- Exhibition halls and temporary structures

As a professional tensile fabric supplier, DERFLEX supports both permanent and temporary membrane structure projects.

Manufacturing Expertise Behind DERFLEX

DERFLEX is not a trading company. We operate as a manufacturing-driven enterprise with complete control over raw materials, coating processes, and quality management.

Production Capabilities

- High-speed PVC coating lines

- Precision knife-over-roll coating technology

- Advanced calendaring and laminating systems

- In-house tensile strength and aging testing

Quality Assurance

- ISO-certified production systems

- Strict batch consistency control

- Full traceability of raw materials

- Project-specific quality documentation

EEAT: Expertise, Experience, Authority, Trust

DERFLEX builds long-term trust by combining technical expertise with real-world project experience.

- Years of specialization in coated fabrics

- Global supply experience across diverse climates

- Proven performance in large-scale projects

- Transparent technical data and testing reports

Our reputation as a reliable tensile fabric supplier is built on consistent quality and professional service.

Customization & OEM Services

Every tensile structure project presents unique technical and aesthetic requirements. DERFLEX offers flexible OEM and customization services including:

- Custom fabric weights and thickness

- Tailored tensile strength specifications

- Special surface finishes and colors

- Project-based fire retardant standards

- Private labeling and packaging

Comparison: Tensile Fabric vs Traditional Roofing Materials

| Material | Weight | Span Capability | Design Flexibility | Maintenance |

|---|---|---|---|---|

| Tensile Fabric | Very Light | Excellent | Very High | Low |

| Steel Roofing | Heavy | Limited | Low | Medium |

| Concrete | Very Heavy | Poor | Very Low | High |

Global Supply & Project Support

DERFLEX supplies tensile fabrics to architects, fabricators, and contractors worldwide.

Our logistics system supports:

- Bulk roll shipments

- Project-based delivery schedules

- Export documentation and compliance

- Technical consultation support